Optical fiber connection structure

An optical fiber connection and optical fiber technology, which is applied in the structural field of connecting two optical fibers, can solve the problems of dust collection, difficult to cause dust collection effect, etc., and achieve the effect of simple connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Embodiments of the present invention will be described in detail below with reference to the drawings.

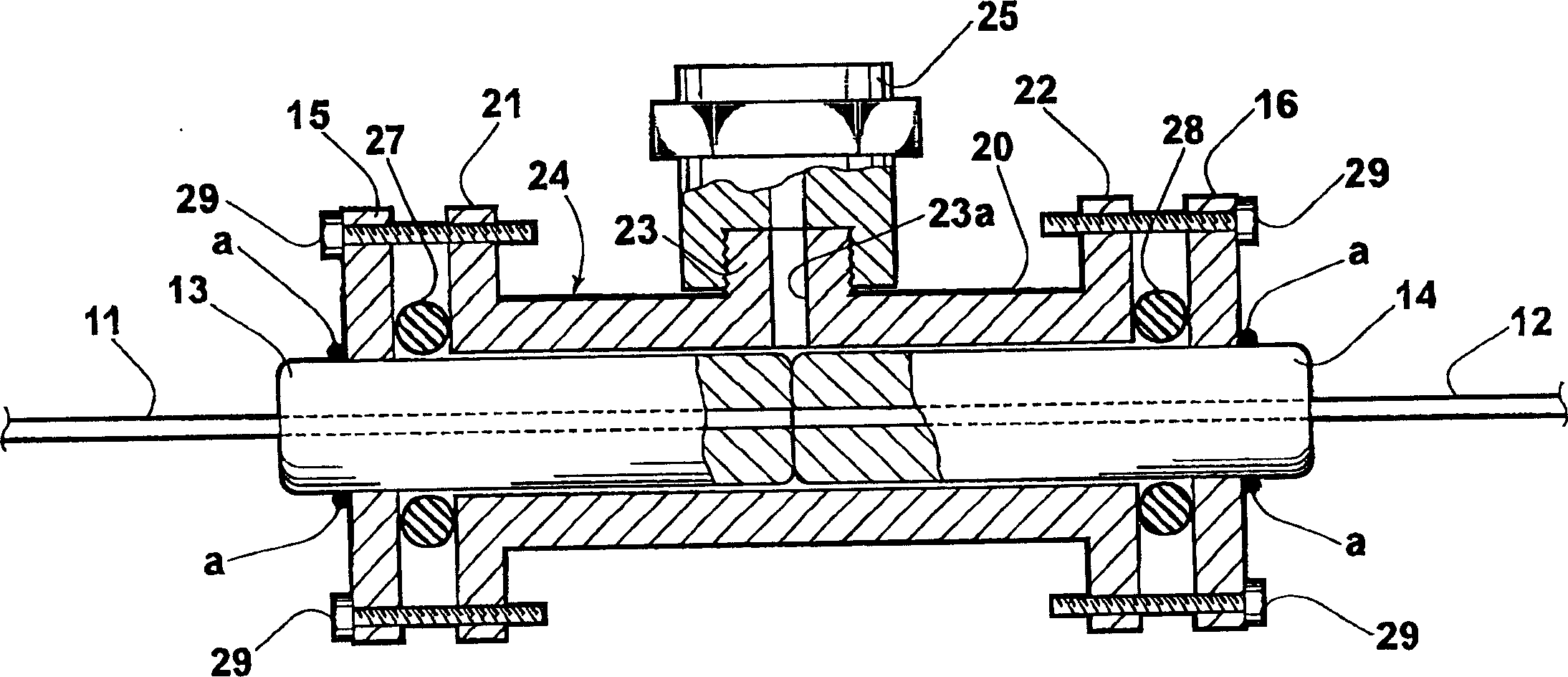

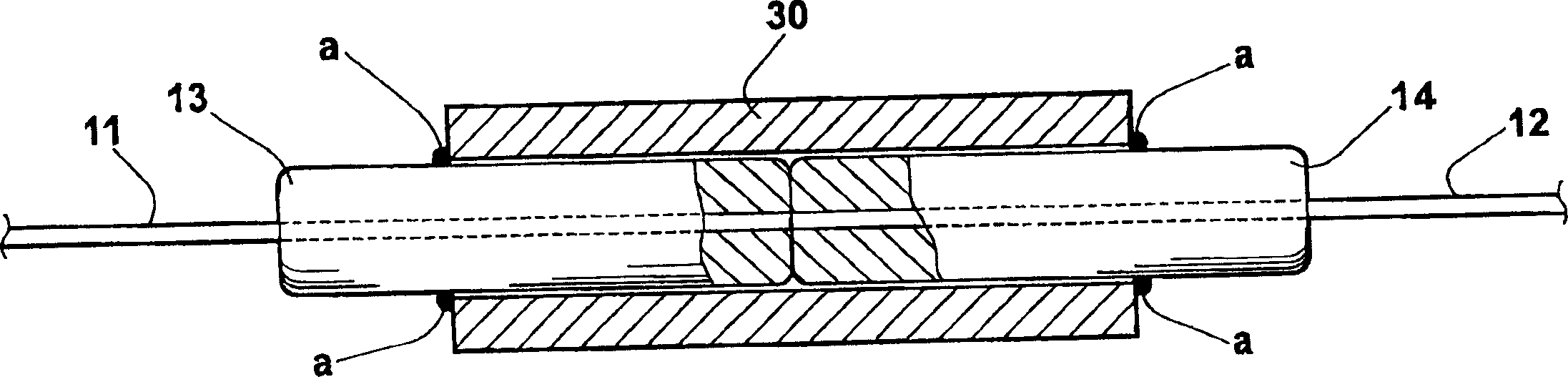

[0046] figure 1 It is a side cross-sectional shape showing the connecting structure of the optical fiber in the first embodiment of the present invention. The connection structure of this optical fiber has two multimode optical fibers (hereinafter referred to as optical fibers) 11,12, each front end of which is inserted and fixed to two cylindrical ferrules 13,14 of the front end; in these ferrules 13,14 Circular flanges 15, 16 fixed near each rear end of each rear end; connector 24 inserted through ferrule 13, 14; O-ring 27 installed on the outer periphery of ferrule 13 inside flange 15; 16 inside and O-ring 28 installed on the outer periphery of ferrule 14.

[0047] The ferrules 13, 14 are formed of ceramics, glass, metal or a combination thereof. In the case of ceramics or glass, it is desirable to metallize the side surface by metal plating or sputtering. Als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com