Building material soleplate

A technology for floor and building materials, which is applied in the direction of architecture, building structure, floor, etc., can solve the problems of peeling off tiles, complicated processes, and complicated resin floor forming molds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

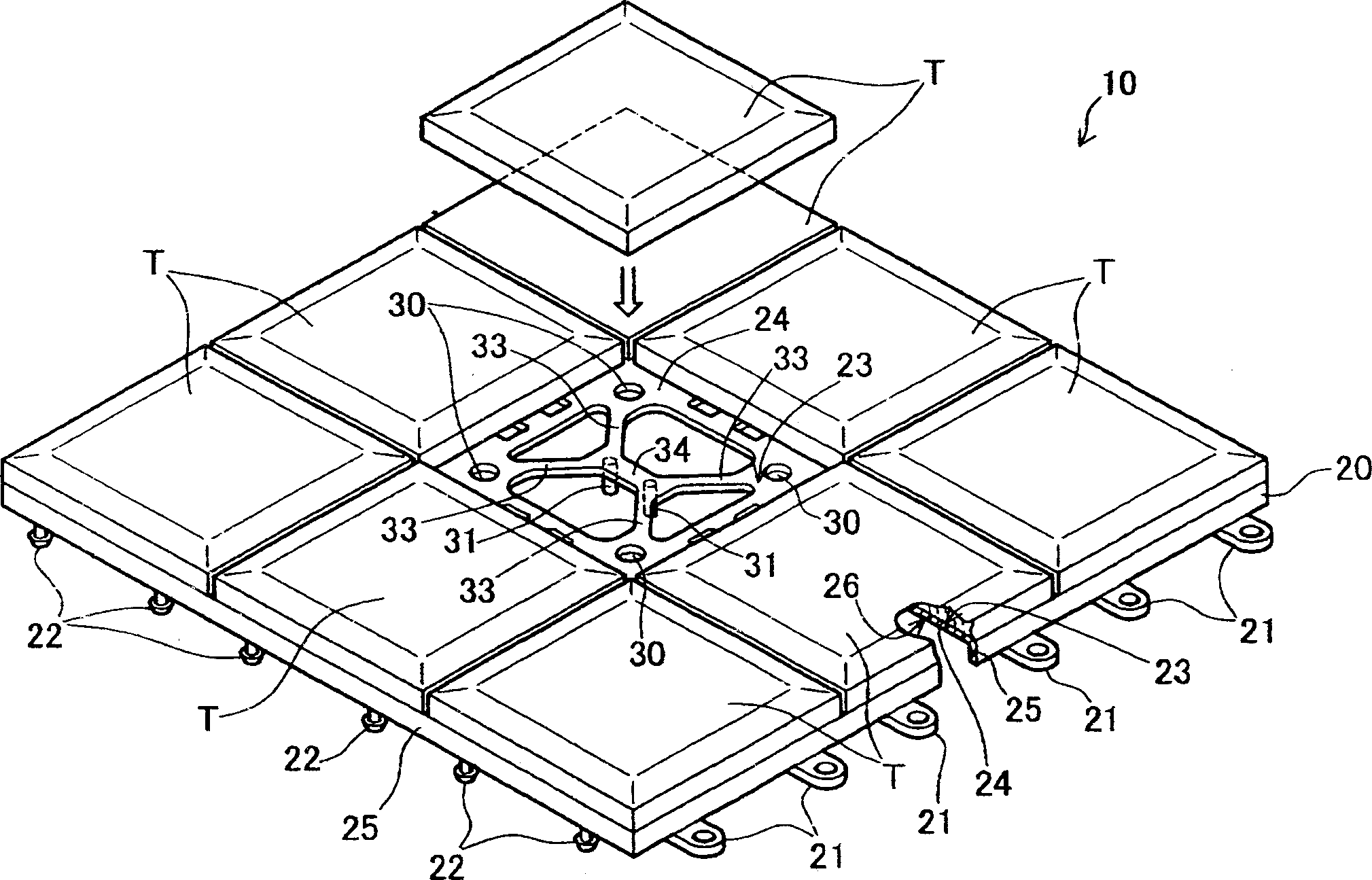

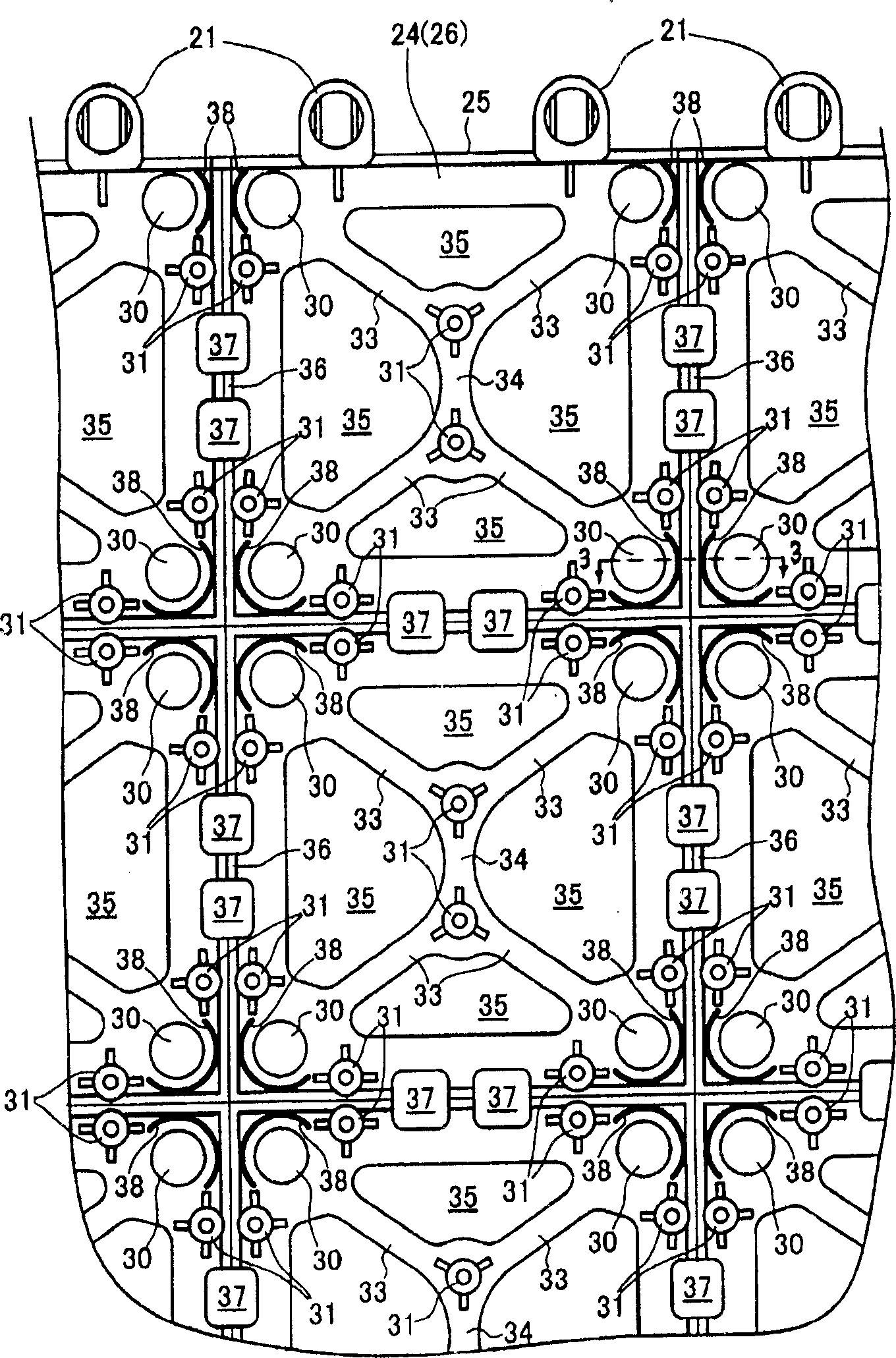

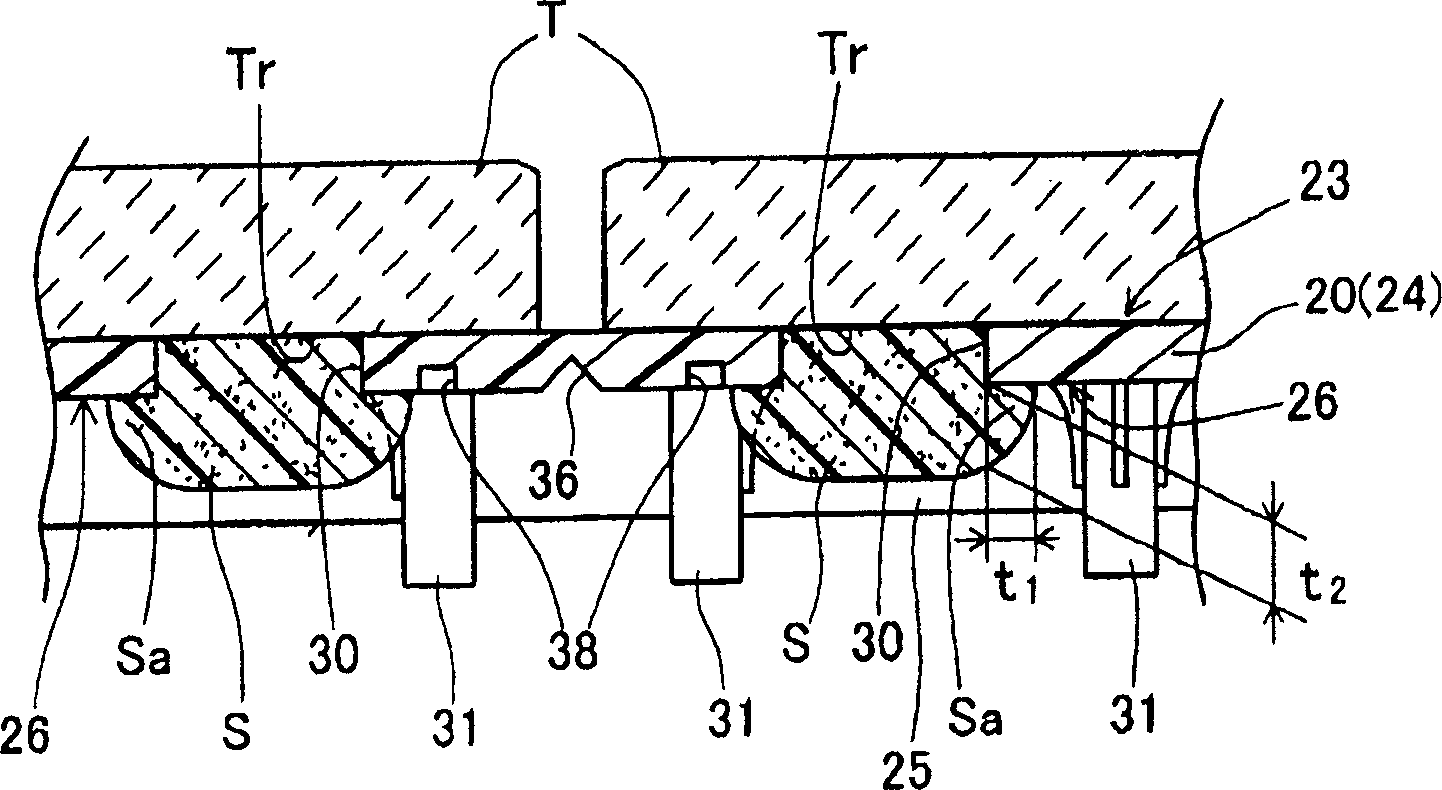

[0029] Hereinafter, embodiments of the present invention will be described based on examples. figure 1 It is a schematic perspective view showing the tile base plate 10 of the embodiment, figure 2 It is an explanatory drawing explaining a part of the bottom surface of the resin base plate 20 which the tile base plate 10 has, image 3 In order to make the facing brick T as the upper ground figure 2 Explanatory diagram of the 3-3 line section in the middle, Figure 4 It is a perspective view schematically showing the main part of the resin base plate 20 .

[0030] As shown in the figure, the tile base 10 is formed by stacking square tiles T in 3×3 rows on the upper surface (the upper surface 23 ) of the square resin base 20 . The tile bottom plate 10 can be connected in the left-right direction and the front-back direction in the figure, and the end piece of the resin bottom plate 20 has a connecting arm 21 for this connection and a connecting hook 22 inserted therein.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com