Heat pump type hot water supply system with cooling function

A hot water supply and heat pump technology, applied in the field of heat pump hot water supply system, can solve the problems of high equipment cost and operating cost, and achieve the effect of realizing the cooling function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

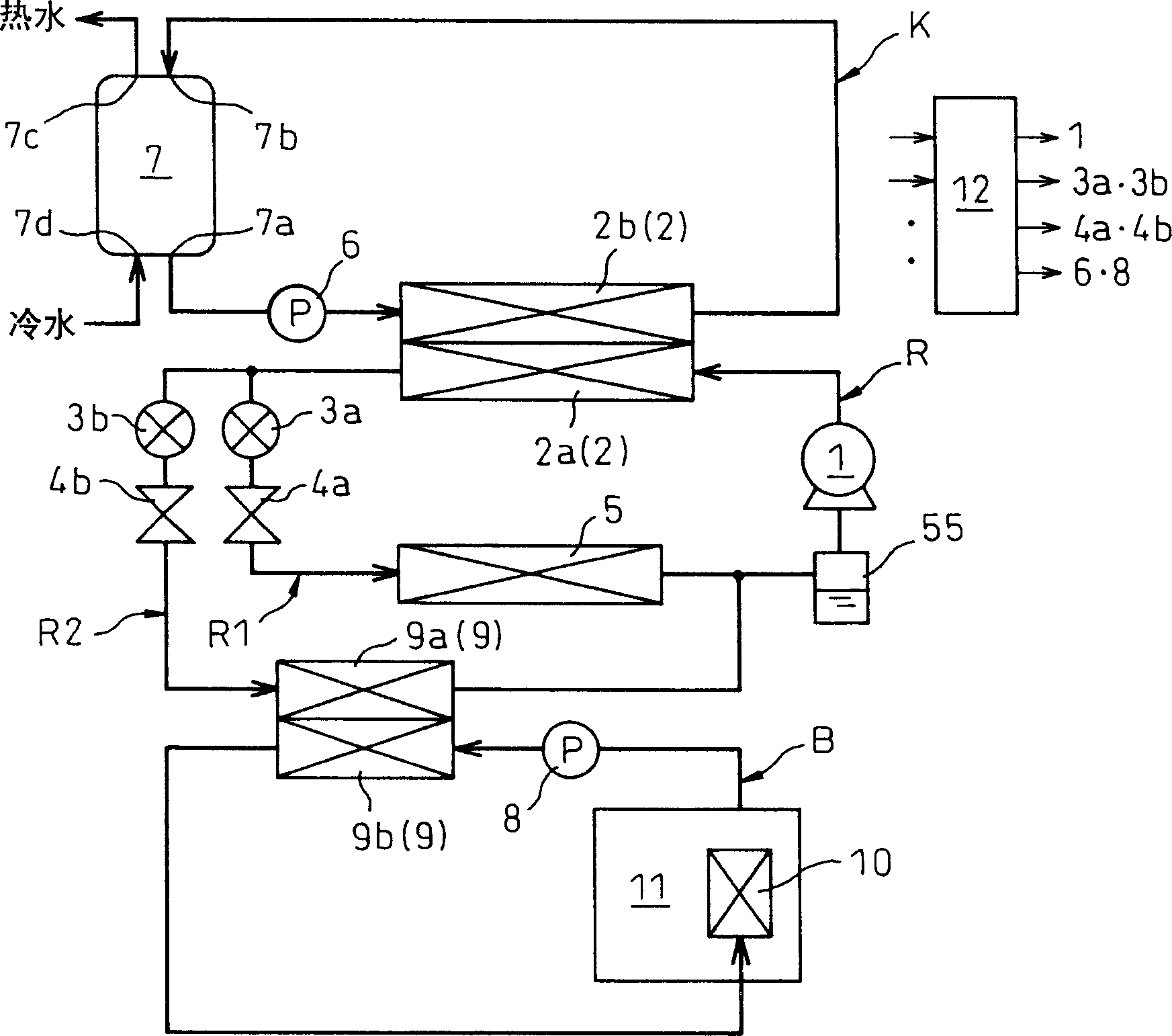

no. 1 example

[0040] Hereinafter, an embodiment of the present invention will be described with reference to the drawings. figure 1 It is a schematic configuration diagram of a heat pump hot water supply system with cooling function according to the first embodiment of the present invention, wherein water is heated to supply hot water while brine is cooled at the same time. In the heat pump type hot water supply system with cooling function according to the current embodiment, using a supercritical heat pump cycle, water is heated to a certain high temperature (about 90°C in the current embodiment) while being cooled using brine as described below The heat exchanger 9, brine such as an antifreeze solution or the like as a heat exchange medium, is cooled to a certain low temperature (about -10°C in the present embodiment). In this way, brine is used to cool a certain space or end 11, such as a refrigerator, freezer or wine cellar.

[0041] A supercritical heat pump cycle (hereinafter referr...

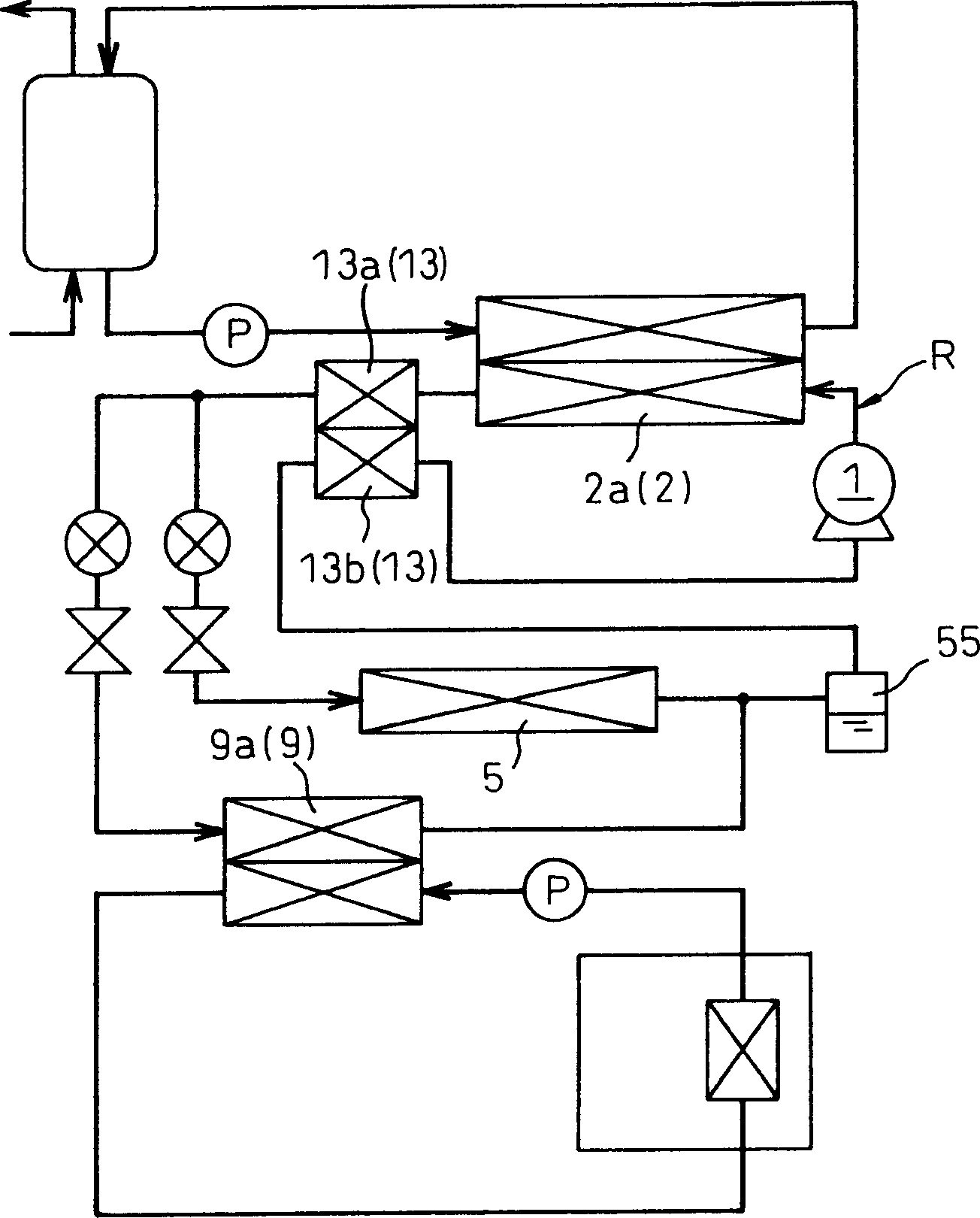

no. 2 example

[0064] figure 2It is a schematic structural diagram of a heat pump hot water supply system with cooling function according to the second embodiment of the present invention. The difference between the present embodiment and the above-mentioned first embodiment is that: according to the present embodiment, the refrigerant circuit R includes: a refrigerant heat radiation heat exchanger 13 having a high-pressure refrigerant passage 13a (in which flows through water High-pressure refrigerant of heat exchanger 2) and low-pressure refrigerant passage 13b (in which low-pressure refrigerant flowing through air heat exchanger 5 or brine cooling heat exchanger 9 flows). By heating the low-temperature refrigerant flowing through the low-pressure refrigerant passage 13b, the heat of the high-pressure refrigerant flowing in the high-pressure refrigerant passage 13a is radiated.

[0065] Unlike conventional systems that use internal heat exchangers to increase compressor extraction pressu...

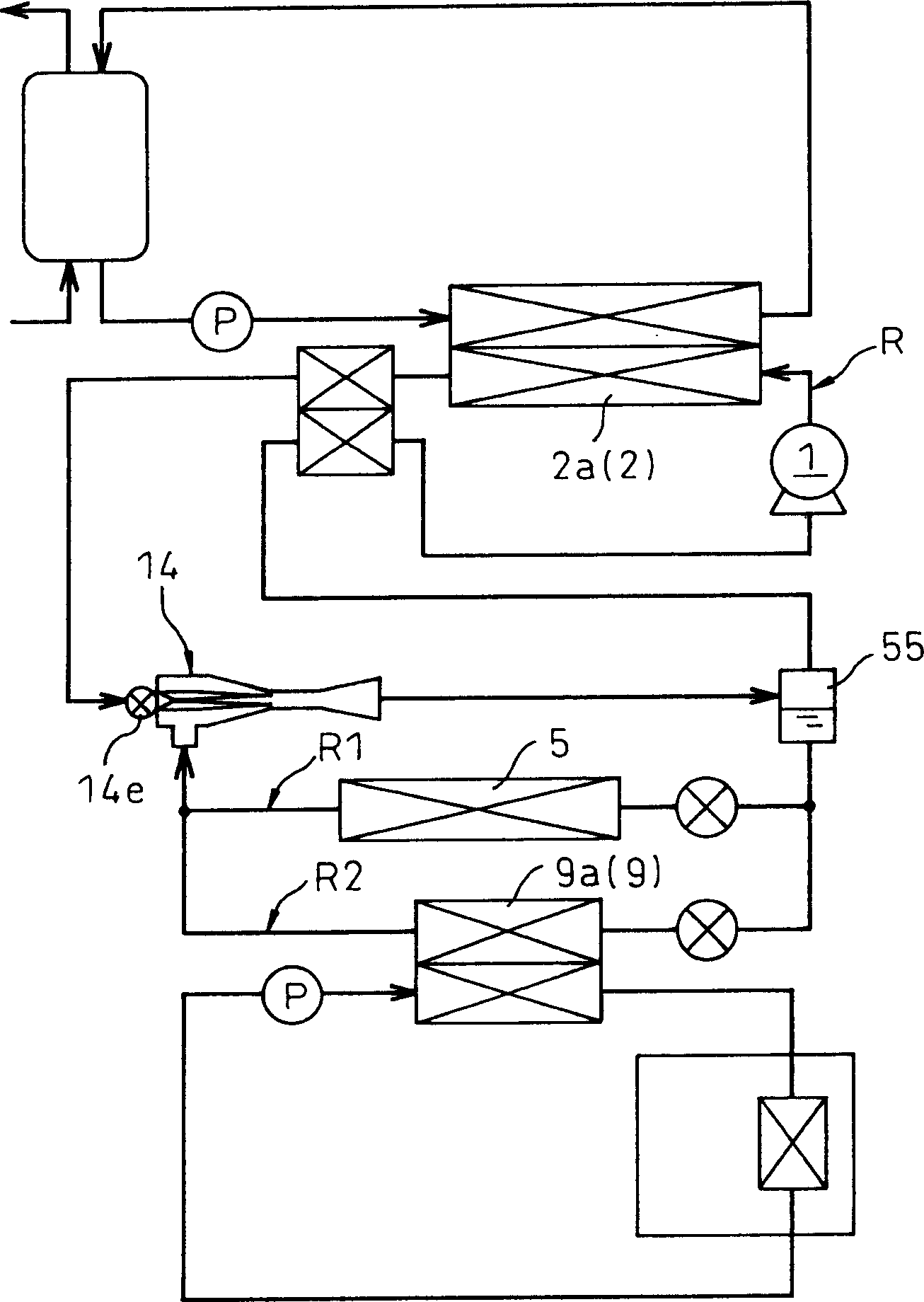

no. 3 example

[0068] image 3 It is a schematic structural diagram of a heat pump hot water supply system with cooling function according to the third embodiment of the present invention. The present embodiment differs from the second embodiment described above in that, according to the present embodiment, the first and second expansion valves 4a, 4b are replaced with the ejector 14 as the decompression expansion means. refer to Figure 4 The structure of the injector 14 constituting the characteristic of the present invention is explained.

[0069] The ejector 14 includes: a nozzle 14a, which is used to convert the pressure energy (pressure head) of the high-pressure refrigerant compressed by the refrigerant compressor 1 and flowing through the compressed water heat exchanger 2 into velocity energy (velocity head), Thereby, the refrigerant is decompressed and expanded; an extraction part 14b: utilizes the high-speed refrigerant flow ejected from the nozzle 14a to extract the evaporated w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com