Reinforced concrete roof laying technology and dedicated vacuum tube

A reinforced concrete and vacuum tube technology, applied in the direction of roof, building, building structure, etc., can solve the problem of increasing the compression weight of the lower concrete layer of the roof, failing to achieve mutual involvement and supporting decompression, and increasing the roof slump and crack coefficient. and other problems, to achieve the effect of saving manpower and material resources, reducing manufacturing costs, reducing slump and crack coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

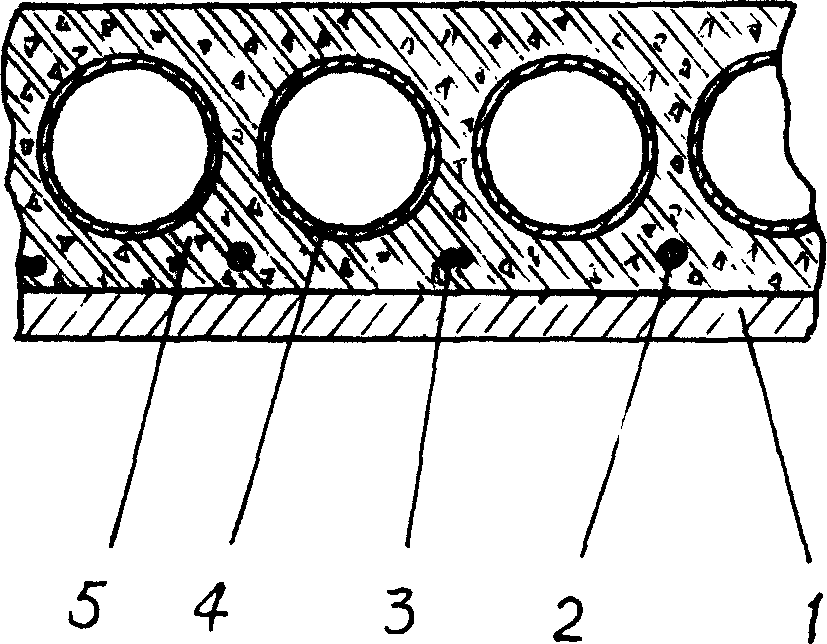

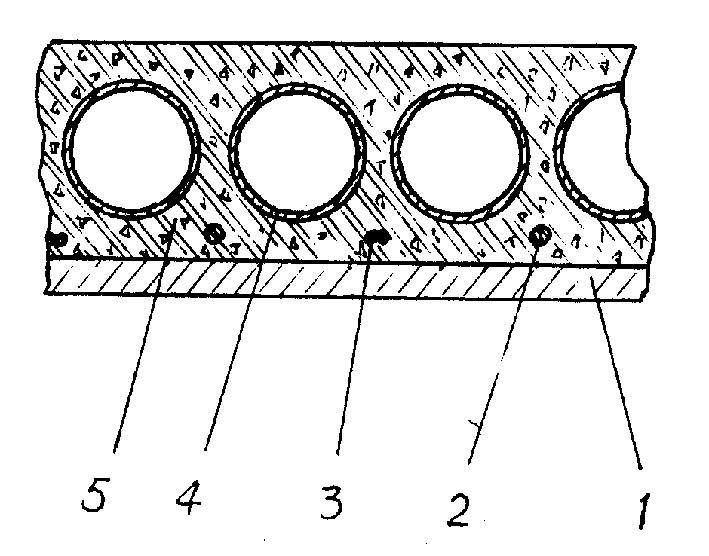

[0013] Reinforced concrete roof pouring technical method of the present invention, combines figure 1 , take the manufacture of a roof with a width of 4 meters as an example to describe in detail:

[0014] a. Support the top form 1 with planks and steel plates.

[0015] b. Lay the steel bars side by side at a height of 20mm from the top form. The steel bars are arranged in the form of main and auxiliary bars at intervals, the diameter of the main bar is 10mm; the diameter of the auxiliary bars is 4mm, two in a bundle. After laying a main reinforcement 2, lay out a bundle of auxiliary reinforcement 3 at a distance of 112mm; then, lay a bundle of main reinforcement 2 at an interval of 112mm...and so on until it is fully paved.

[0016] c. The poured concrete layer is up to 30mm thick.

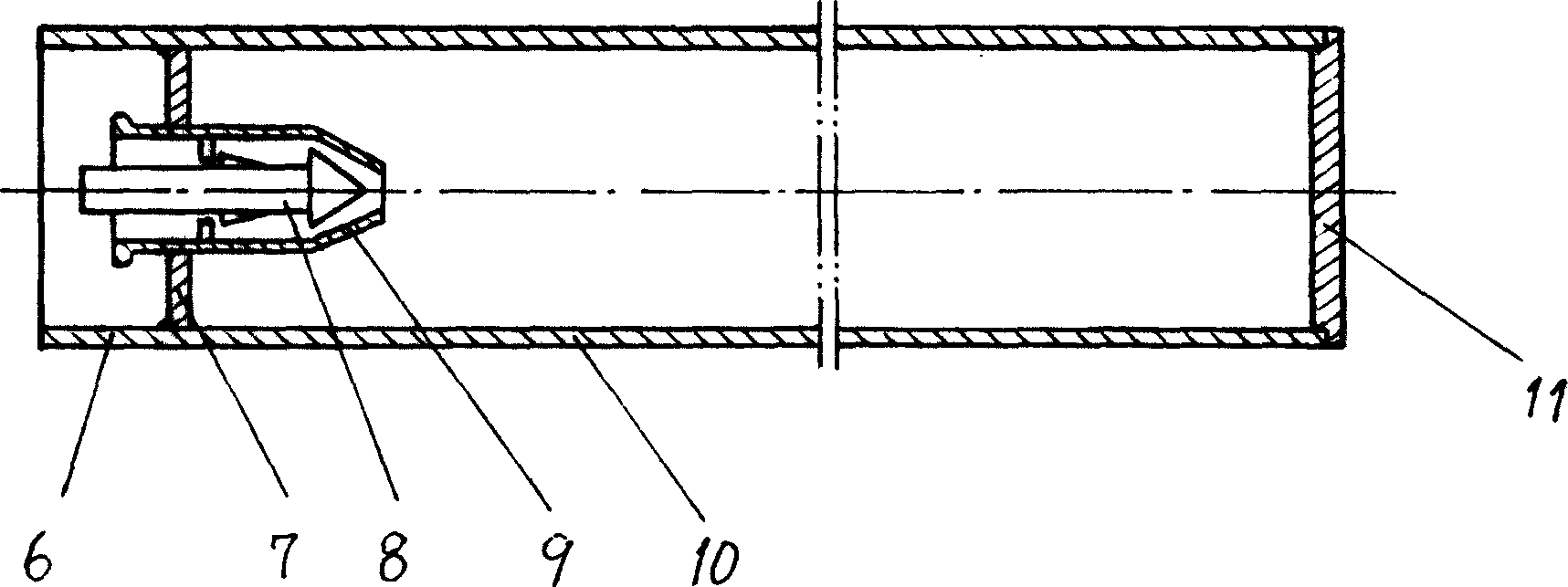

[0017] d. Lay vacuum tubes 4 in the same direction as the steel bars on the concrete layer 5, and each vacuum tube is positioned directly above between two (bundle) steel bars. The diameter (o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com