Producing device for electro-optical device, electro-optic device, and electronic instruments

An electro-optical device and manufacturing device technology, applied in instruments, respiratory filters, optics, etc., can solve problems such as impurities mixed in, liquid crystal display quality degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

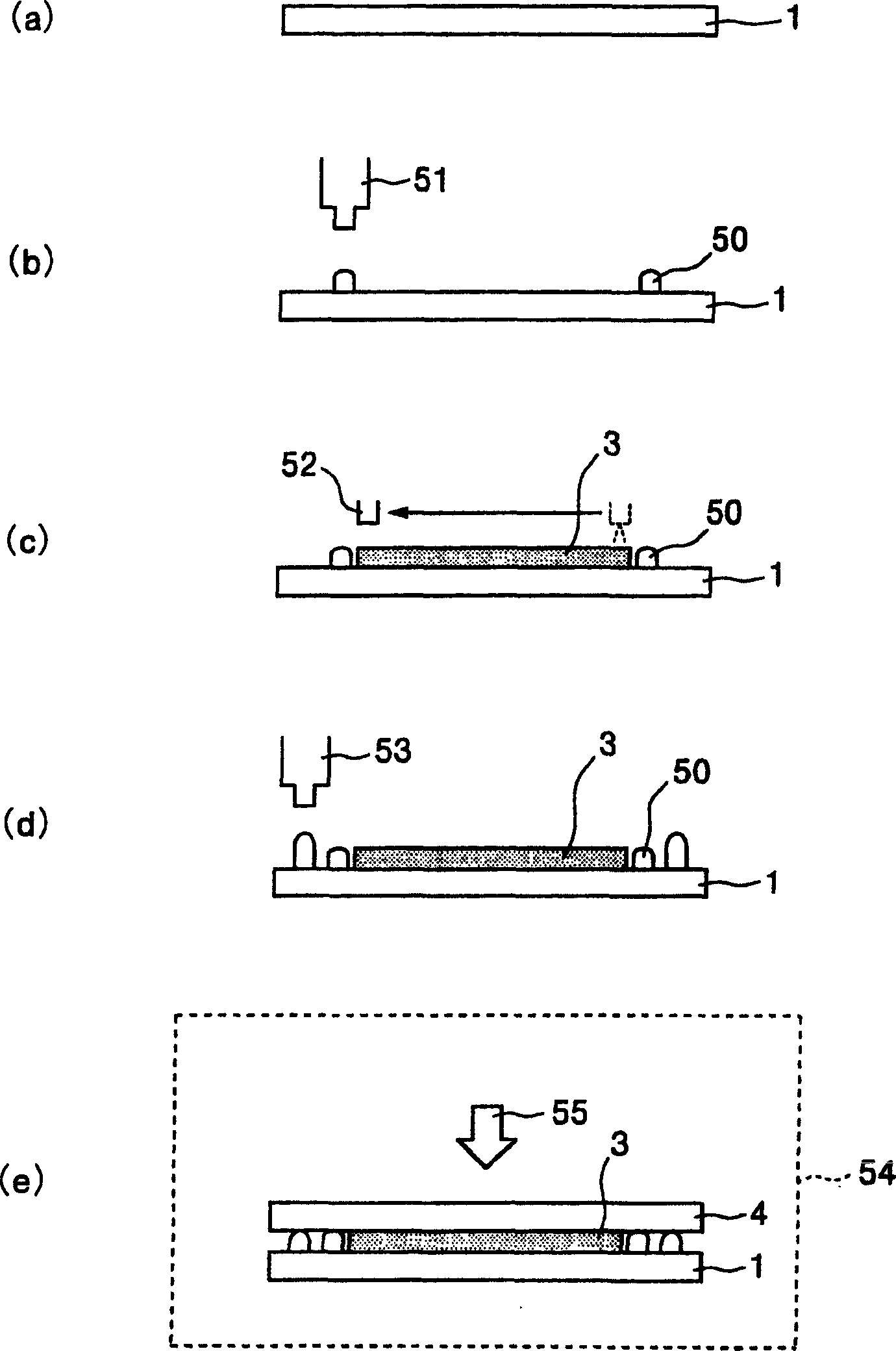

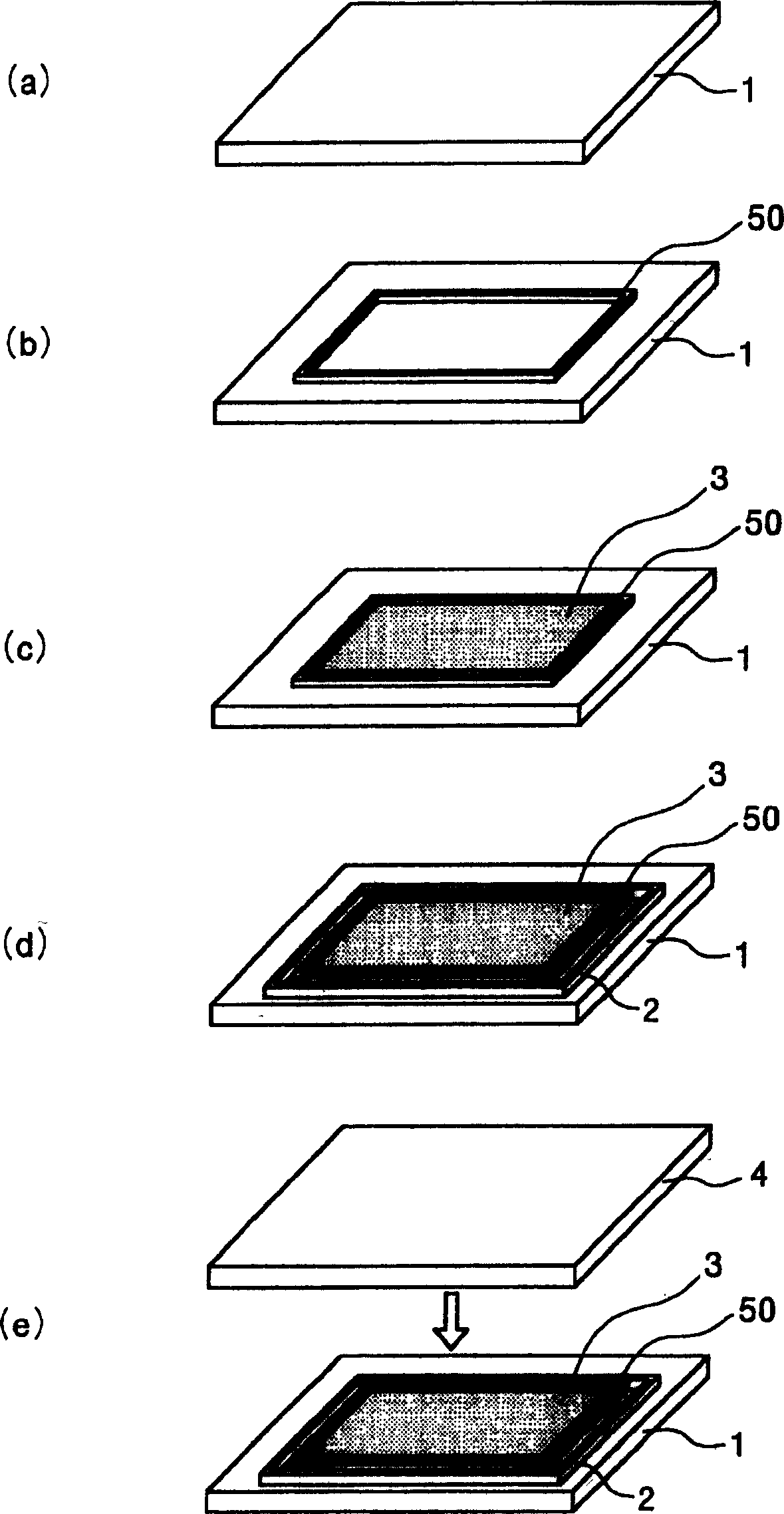

Embodiment 1

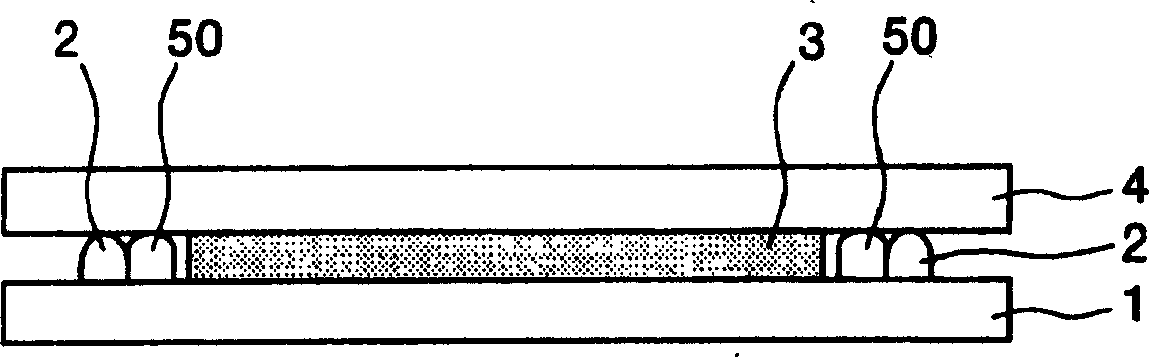

[0043] First, refer to Figure 4 The structure of the liquid crystal display panel which is the electro-optic device of the present invention will be described. The liquid crystal display panel 100 of this embodiment has a first substrate 1 and a second substrate 4 arranged oppositely, and liquid crystal display elements 106 and 107 are respectively formed on the inner surfaces of the first substrate 1 and the second substrate 4 .

[0044] Specifically, as Figure 4 As shown, a reflective film (aluminum, silver) 101, a color filter (CF) 102, a protective (OVC) layer 103, a transparent electrode 104, and an alignment film 105 are sequentially formed on the first substrate 1 as the first substrate side. Liquid crystal display element 106.

[0045] On the other hand, a transparent electrode 104 and an alignment film 105 are formed on the opposite second substrate 4 . The transparent electrode 104 is formed of a transparent electrode material such as ITO (Indium Tin Oxide), pro...

Embodiment 2

[0079] Below, refer to Figure 8 with Figure 9 Specific examples of electronic equipment to which the liquid crystal display panel of the present invention can be applied will be described.

[0080] First, an example in which the liquid crystal display panel of the present invention is applied to a display portion of a portable personal computer (so-called notebook computer) will be described. Figure 8 It is a perspective view showing the mechanism of this personal computer. Such as Figure 8 As shown, a personal computer 91 has a main body 912 provided with a keyboard 911, and a display 913 to which a liquid crystal display panel of the present invention is applied.

[0081] Next, an example in which the liquid crystal display panel of the present invention is applied to a display portion of a mobile phone will be described.

[0082] Such as Figure 9 As shown, in addition to a plurality of operation buttons 921, a mobile phone 92 also has a receiver port 922, a speake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com