Spiral fluorescent light tube

A fluorescent tube, spiral type technology, applied in the field of spiral fluorescent tubes, can solve the problems of limited application, long arc length, affecting the rapid establishment of luminous flux, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

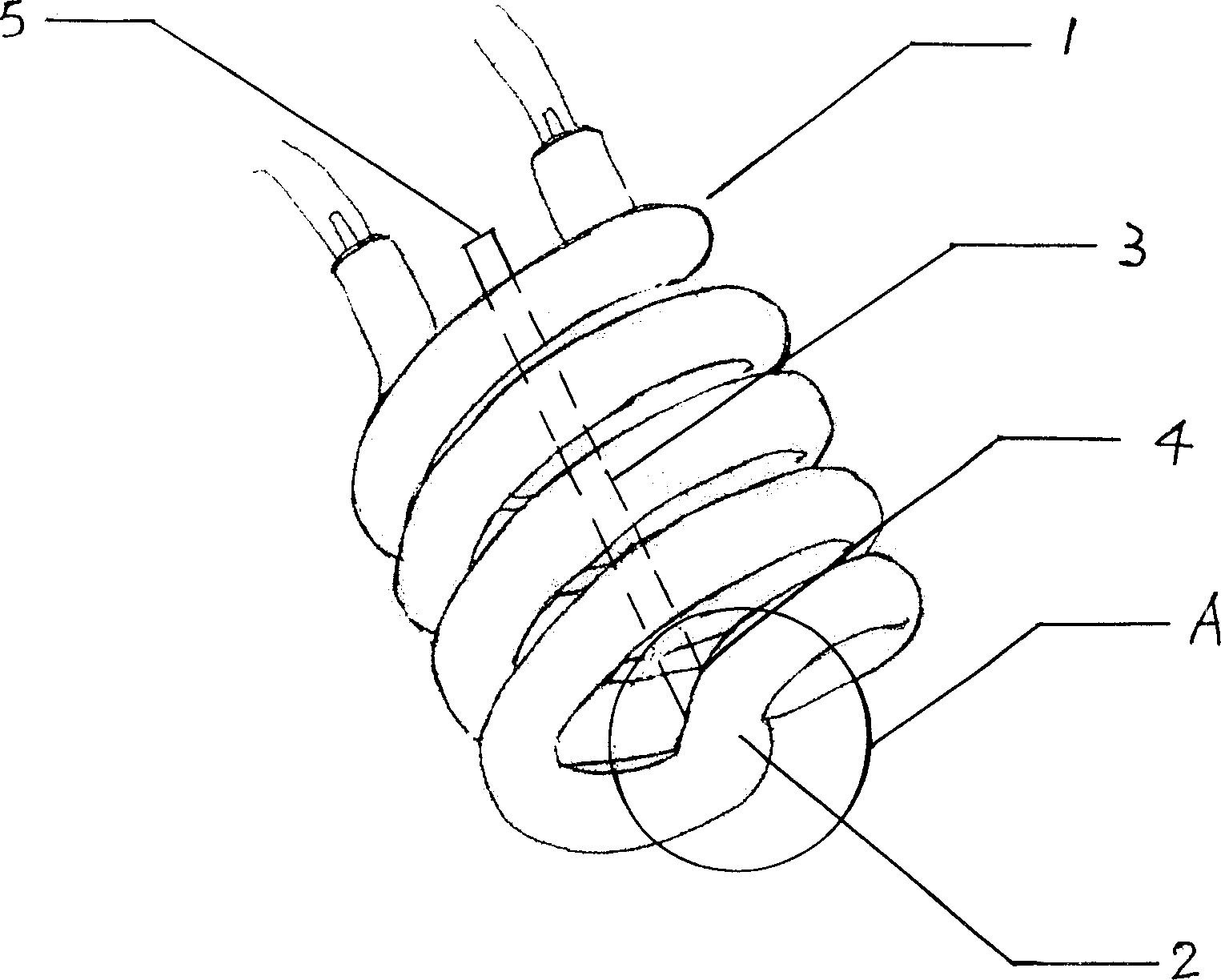

[0008] Such as figure 1 As shown, place one end of the glass tube at the cold end 3 within the range of the top 2 of the spiral fluorescent tube 1, drill a hole in the connecting part 4 of the lamp tube and then seal and connect the cold end tube 3 with the lamp tube 1. When connecting, ensure that the cold The glass tube at end 3 is unimpeded with lamp tube 1.

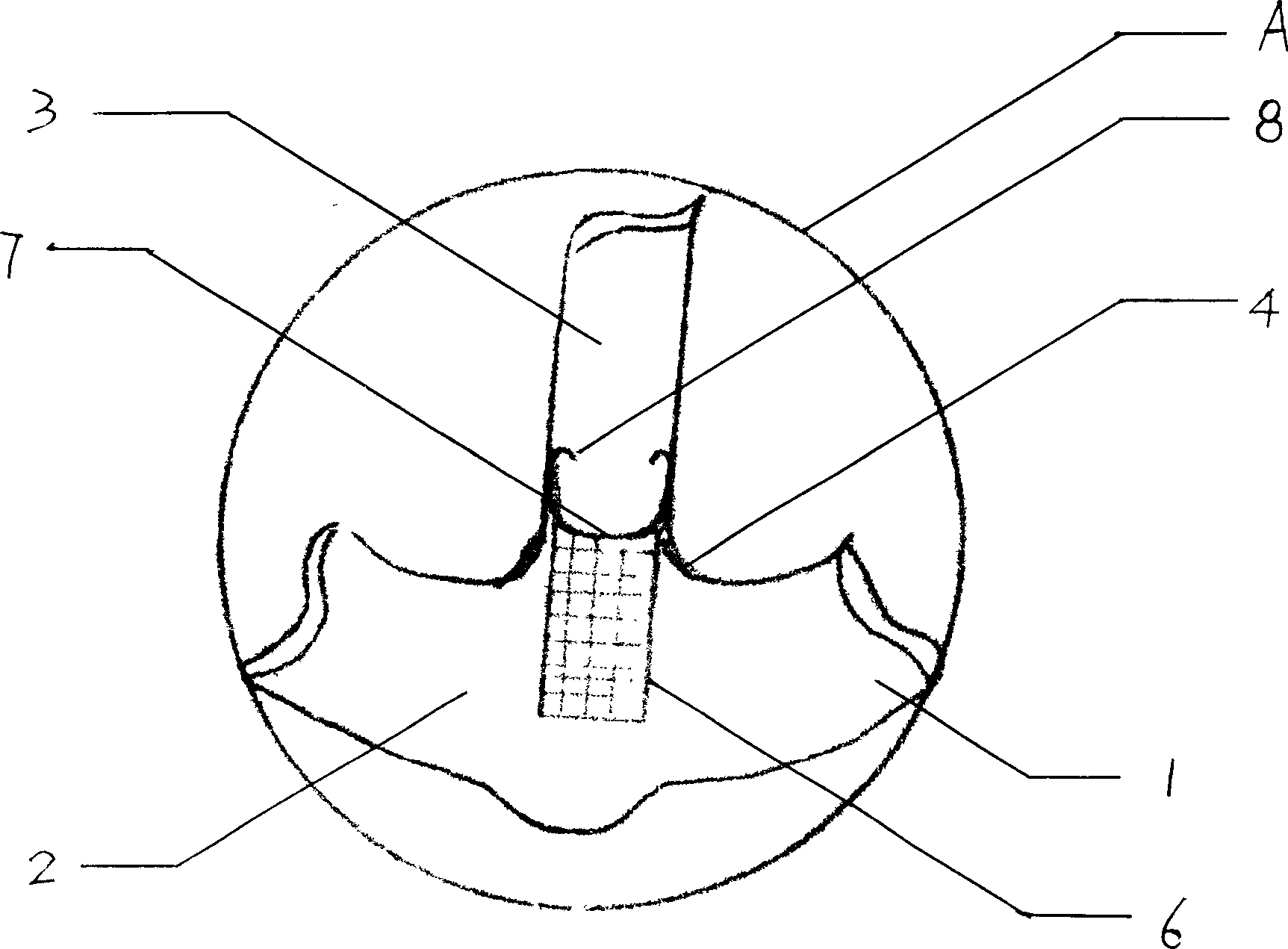

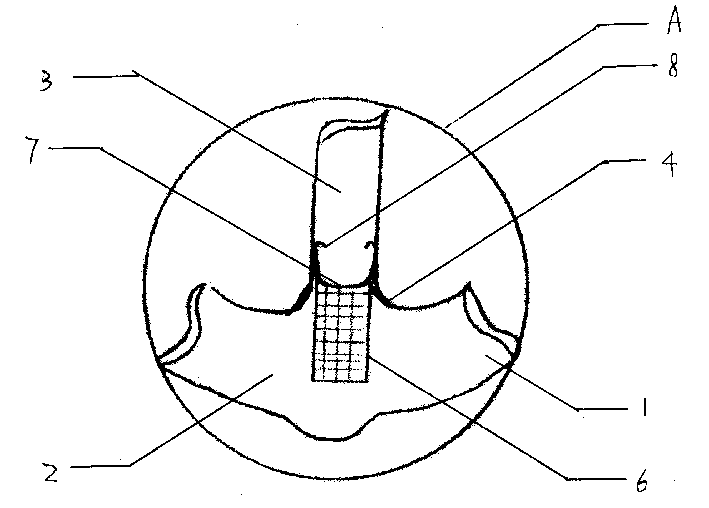

[0009] figure 2 yes figure 1 The expansion diagram of A. After the auxiliary amalgam 6 is connected with the guide wire 8 through the joint 7, the auxiliary amalgam 6 is placed in the lamp tube at the top 2 of the spiral fluorescent tube 1, and the guide wire 8 is placed in the glass tube of the connecting cold end 3, For fixing auxiliary amalgam6. The other end 5 of the connected cold end 3 glass tube is sealed. Since the important photoelectric parameters such as the operating voltage (tube voltage) and luminous efficiency of fluorescent lamps are closely related to the mercury pressure in the tube, the optimu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap