Image forming method and device, manufacture of device, conductive film layout, photoelectric device and electronic machine

A technology for optoelectronic devices and conductive films, which is used in semiconductor/solid-state device manufacturing, conductive pattern formation, and discharge tube/lamp manufacturing. The effect of forming motion, smooth pattern formation, and suppressing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] [Formation method of figure]

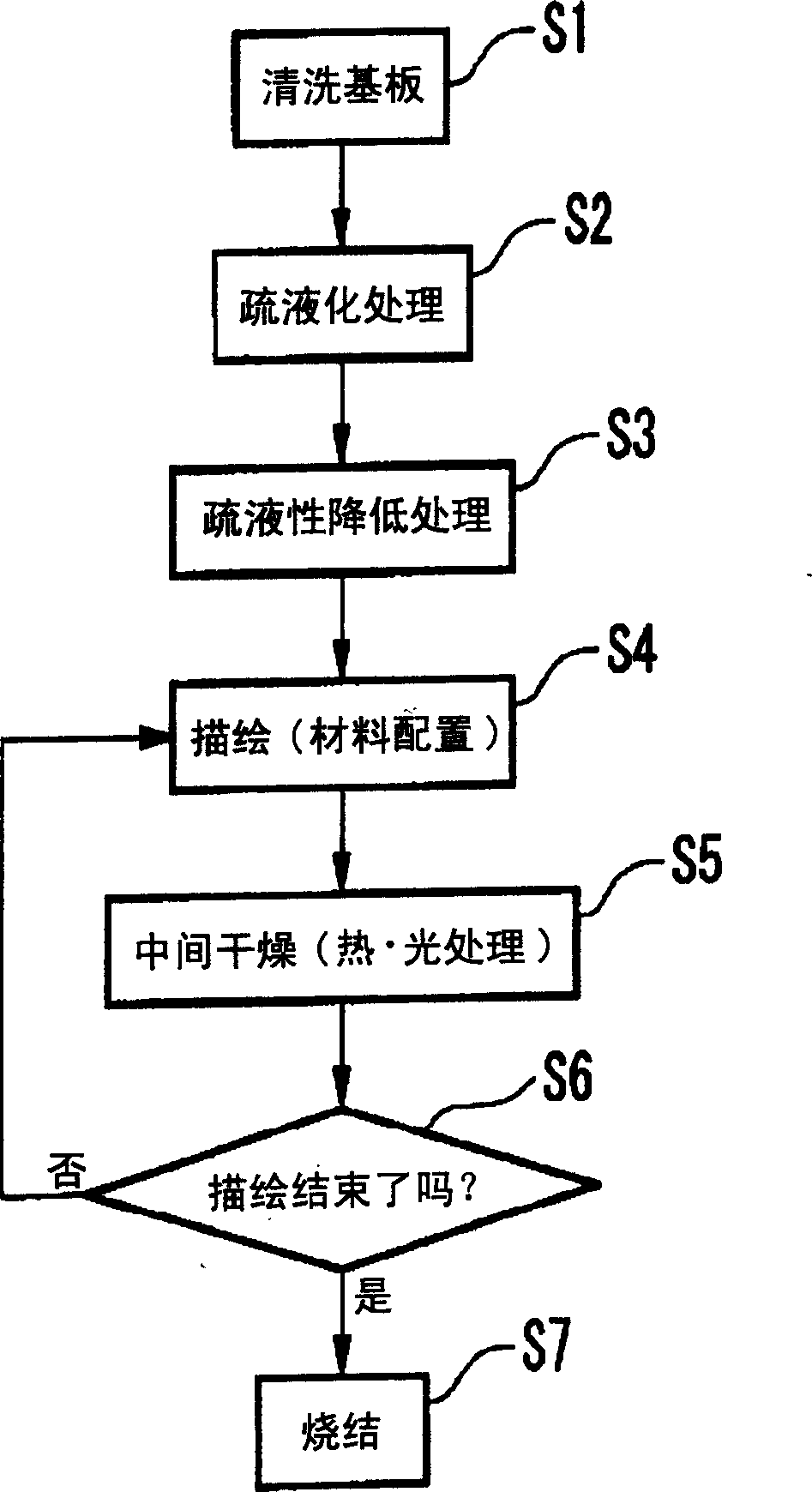

[0047]Next, the pattern forming method of the present invention will be described with reference to the drawings. figure 1 It is a flowchart showing an embodiment of the pattern forming method of the present invention.

[0048] Here, in this embodiment mode, a case where a conductive film wiring pattern is formed on a substrate will be described as an example.

[0049] figure 1 Among them, the pattern forming method according to this embodiment includes: a step of cleaning the substrate on which droplets of the liquid material are placed using a predetermined solvent or the like (step S1); a lyophobic treatment step (step S2) constituting a part of the substrate surface treatment step; adjusting A lyophobic reduction treatment step (step S3) that constitutes a part of the surface treatment process to lyophobicize the surface of the substrate after the lyophobic treatment; disposing the wiring including the conductive film on the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com