Plastic bottle blank heater

A technology for plastic bottles and heaters, which is applied in the field of heaters for plastic preforms, and can solve problems such as uneven temperature in the heating zone, affecting the heating quality of plastic preforms, and inability to adapt to different requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

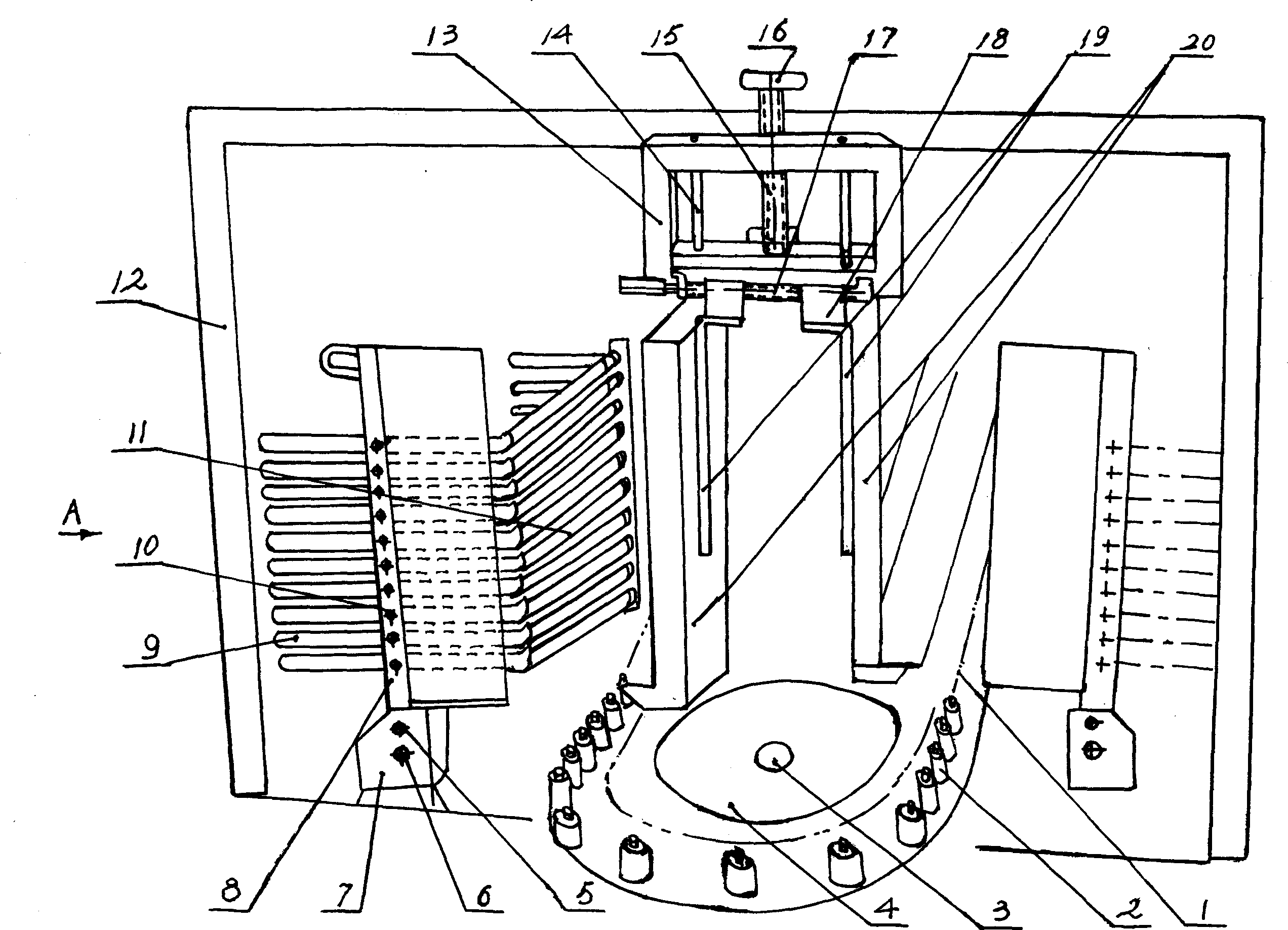

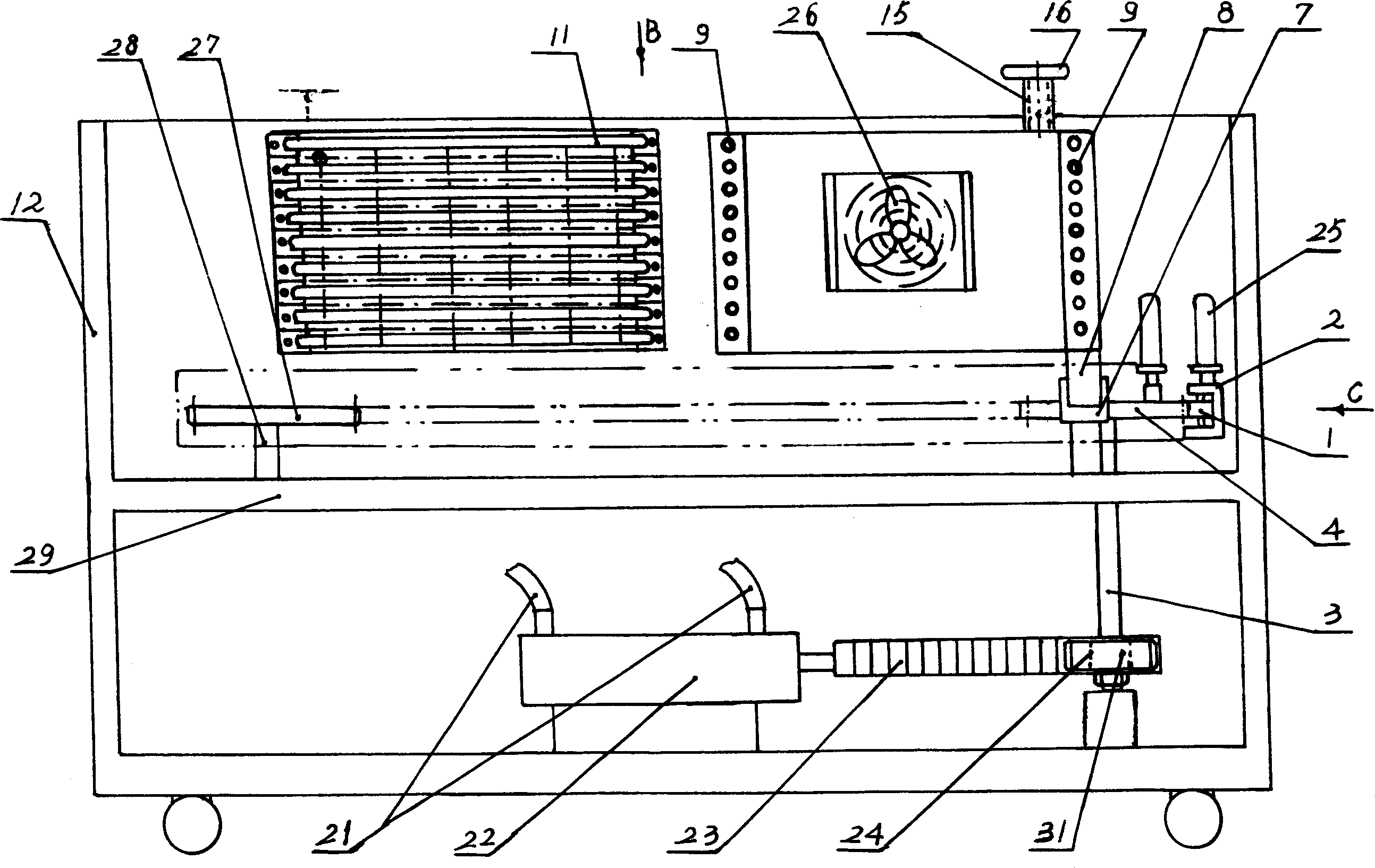

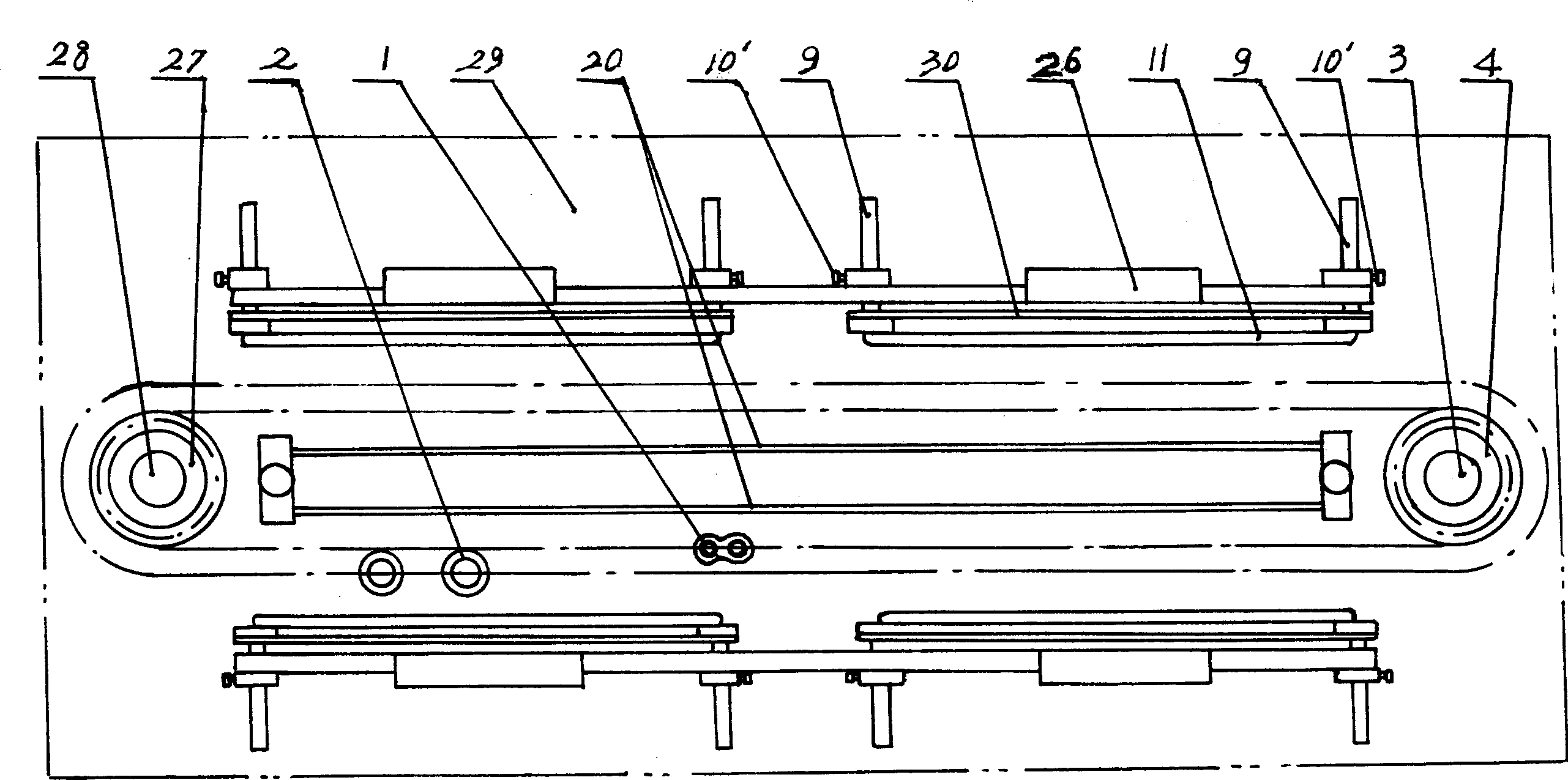

[0007] The invention discloses a plastic bottle preform heater for producing plastic hollow containers. There is a frame 12 of the heater, and the frame 12 is mainly installed to drive the plastic preform to run (including the circular revolution of the plastic preform, such as figure 1 , image 3 Shown, and rotation, rotation is the same as the transmission mechanism of prior art), and the heating device etc. that plastic bottle blank is heated are formed. The heating device is the heating lamp tube 11 located on both sides of the workbench 29 of the frame. When assembling, the two ends of the heating lamp tube 11 are connected with the adjusting rod 9 to form a U shape. The adjusting rod 9 is movably assembled with the bracket, and the bracket is installed on the frame 12. On the workbench 29, the reflection plate 20 corresponding to the heating lamp tube 11 is installed in the middle of the workbench 29. Through the following more specific structure, the bracket for instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com