Valve control apparatus for IC engine

A control device and valve control technology, applied in valve device, engine control, fuel injection control, etc., can solve the problems of reducing weight and manufacturing cost, reducing fuel economy, increasing power consumption, etc., to improve power output, improve Fuel economy, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

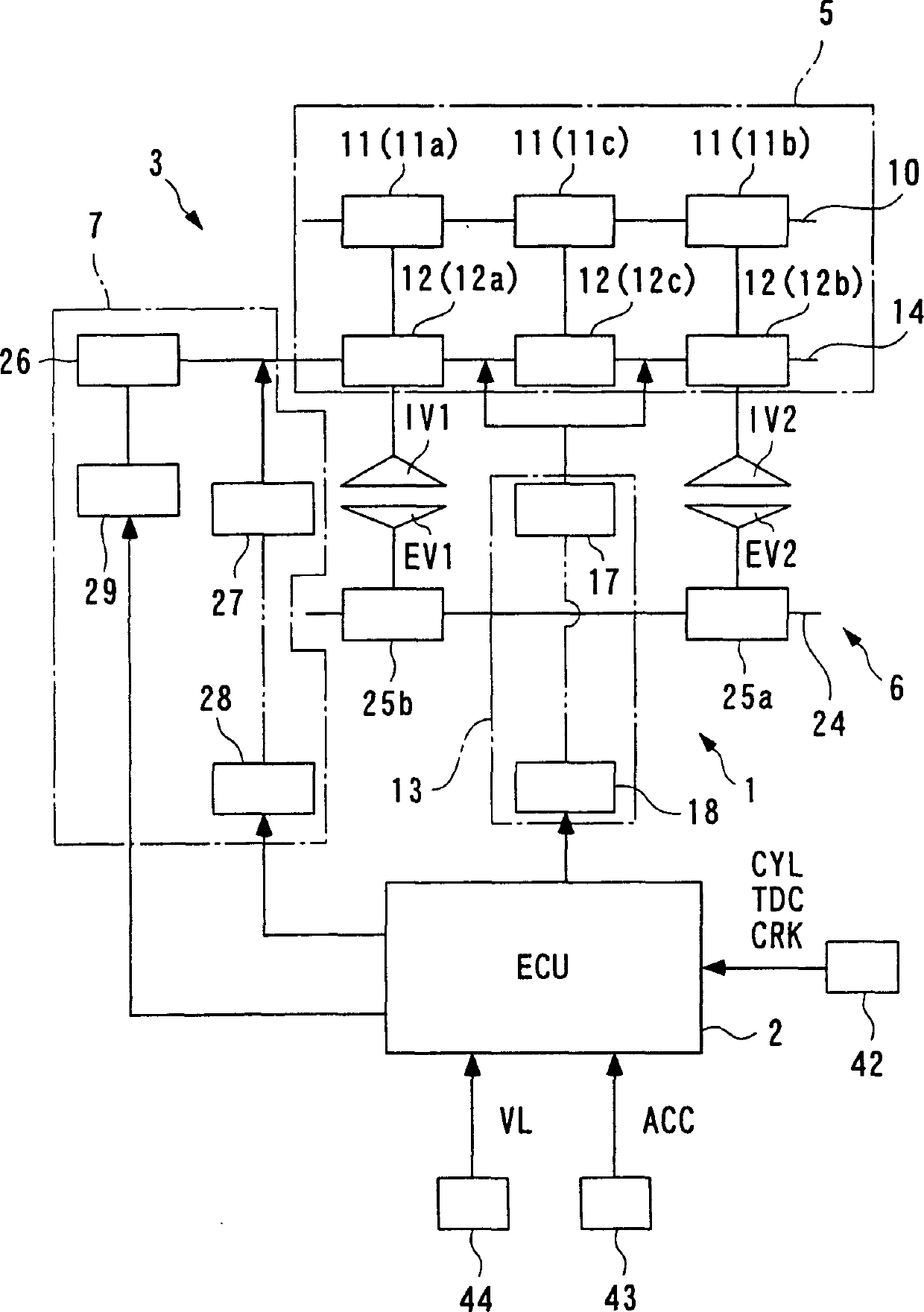

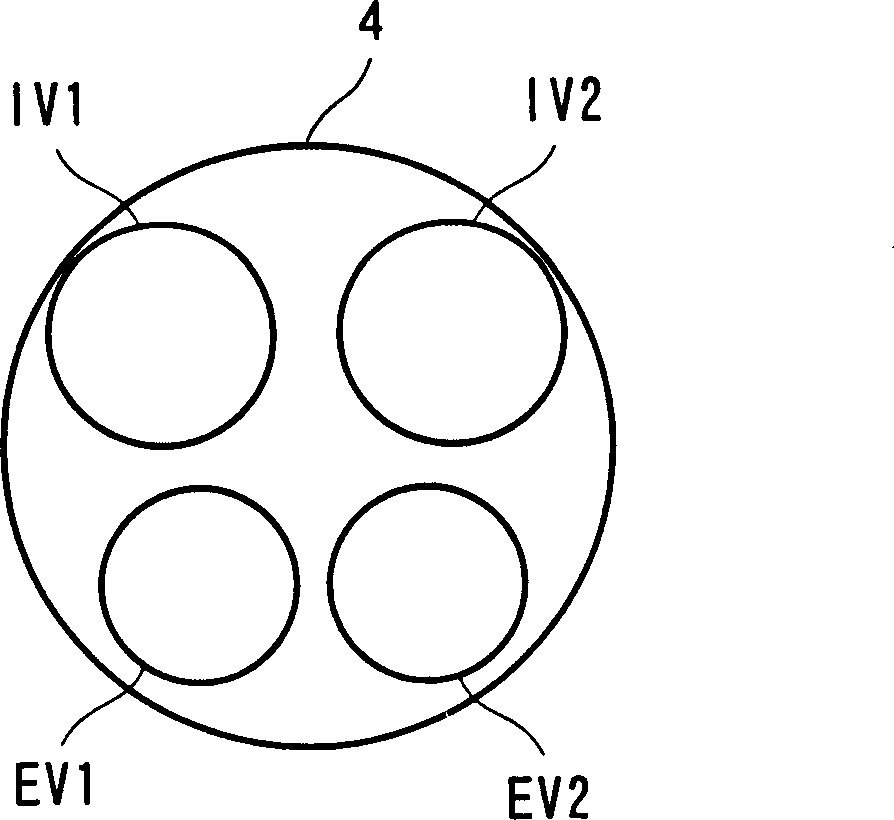

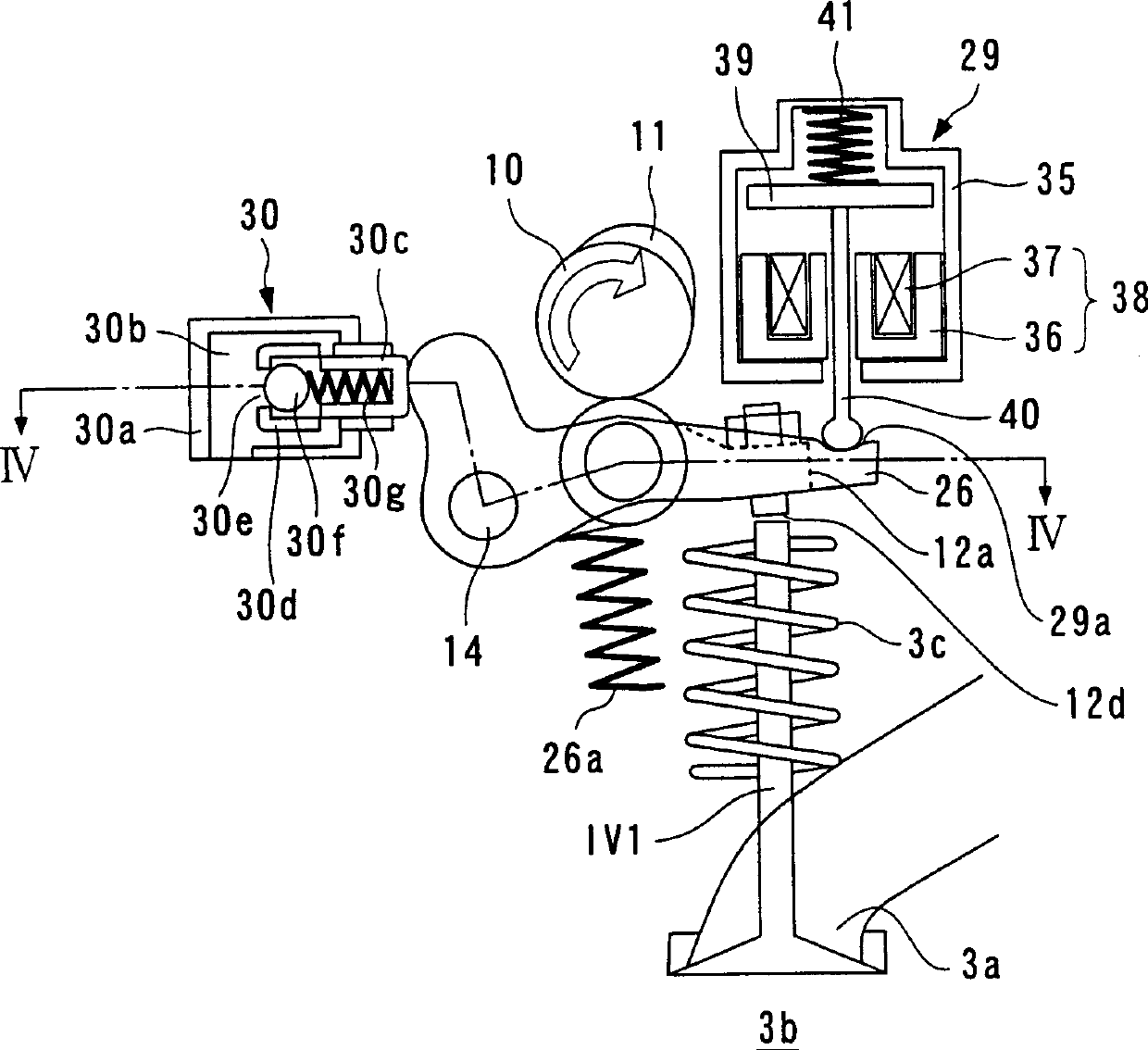

[0057] A valve control device for an internal combustion engine according to an embodiment of the present invention will be described below with reference to the drawings. Fig. 1 schematically shows the structure of a valve control device to which the present invention is applied. An internal combustion engine (hereinafter referred to as "engine") 3 shown therein is a four-cylinder (only one cylinder is shown in FIG. 2 ) in-line DOHC engine mounted on a vehicle not shown. As shown in FIG. 2, each cylinder 4 is provided with first and second intake valves IV1, IV2 and first and second exhaust valves EV1, EV2 as engine valves. As shown in FIG. 3 showing an example of the first suction valve IV1, the suction valves IV1, IV2 are arranged such that they can respectively be in the closed position (shown in FIG. 3 ) for closing the suction port 3a of the engine 3 and an open position (not shown) for opening the suction port 3a, in which the suction valve protrudes into the combustio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com