AIr conditioner flow divider

A shunt and air conditioner technology, which is applied to the details of space heating and ventilation, heating methods, lighting and heating equipment, etc. Heat exchange capability, easy positioning, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

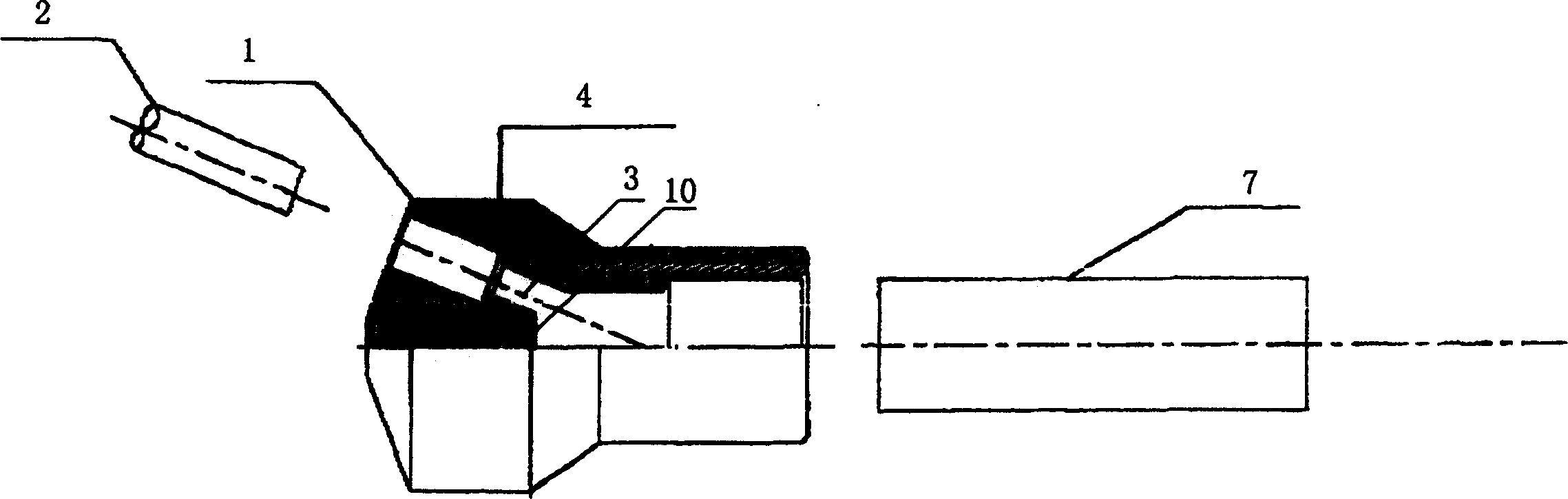

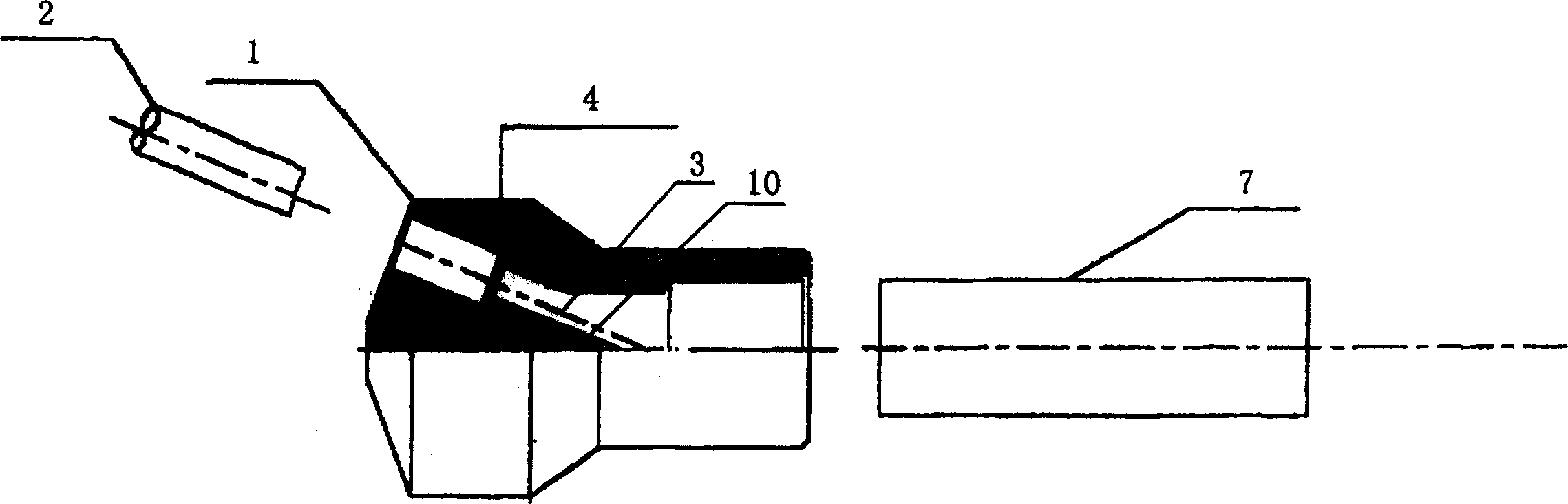

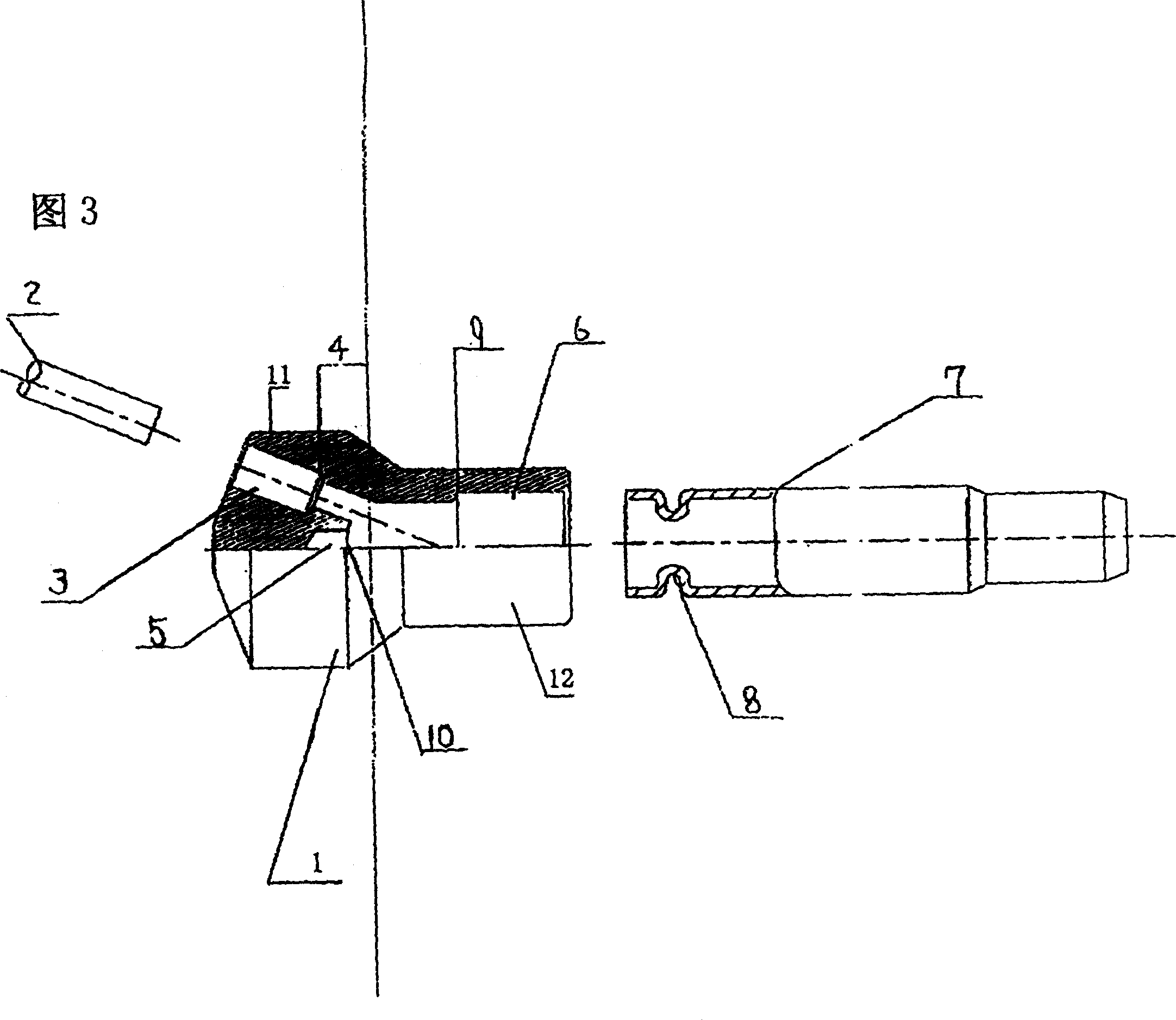

[0019] Referring to FIG. 3, it is a half-sectional view of the liquid distribution head of the air conditioner flow divider of the present invention. As shown in FIG. 3 , the bottom surface of the cavity of the liquid distributor 1 is a groove 5 , and the liquid distributor 1 is composed of a head 11 and a cylinder 12 . There are multiple liquid distribution holes 3 in the head 11 of the liquid distribution head to form a multi-way shunt, such as four-way shunt, the distribution holes 3 are evenly distributed on the arc of the head 11 of the liquid distribution head, and the liquid distribution holes 3 are variable diameters. For the hole, the aperture near the outside is large, and the aperture in the inside is small, and the branch pipe 2 can be inserted into the large hole to the variable diameter part 4 for positioning.

[0020] An inner groove 5 is arranged on the bottom surface of the inner cavity of the liquid-dispensing head 1, and the inner groove 5 is arranged in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com