Apparatus for mixing and reacting at least tow fluids

A fluid and equipment technology that is applied in the field of small-scale or micro-mixing operations and can solve problems such as large structures and high pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

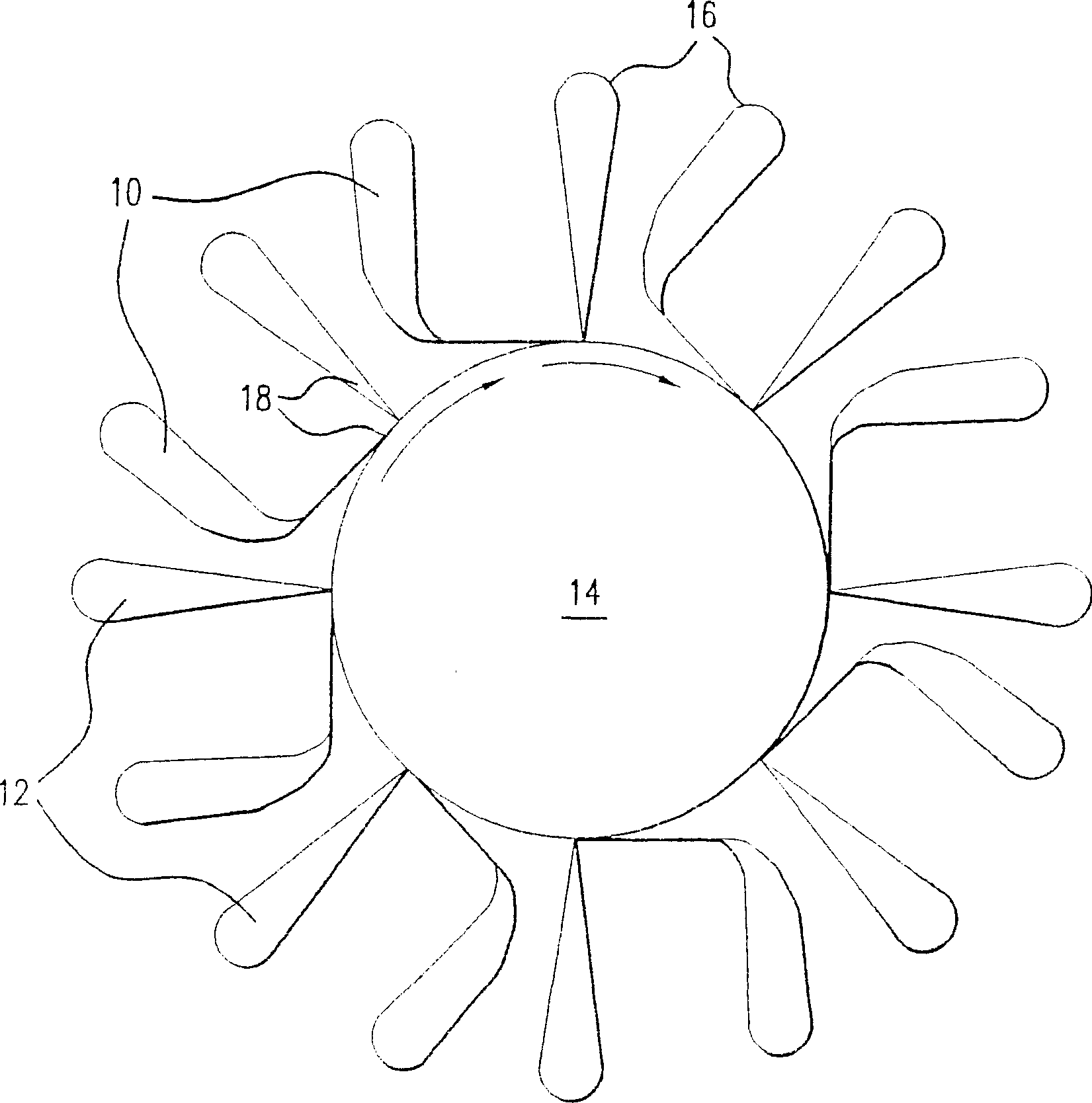

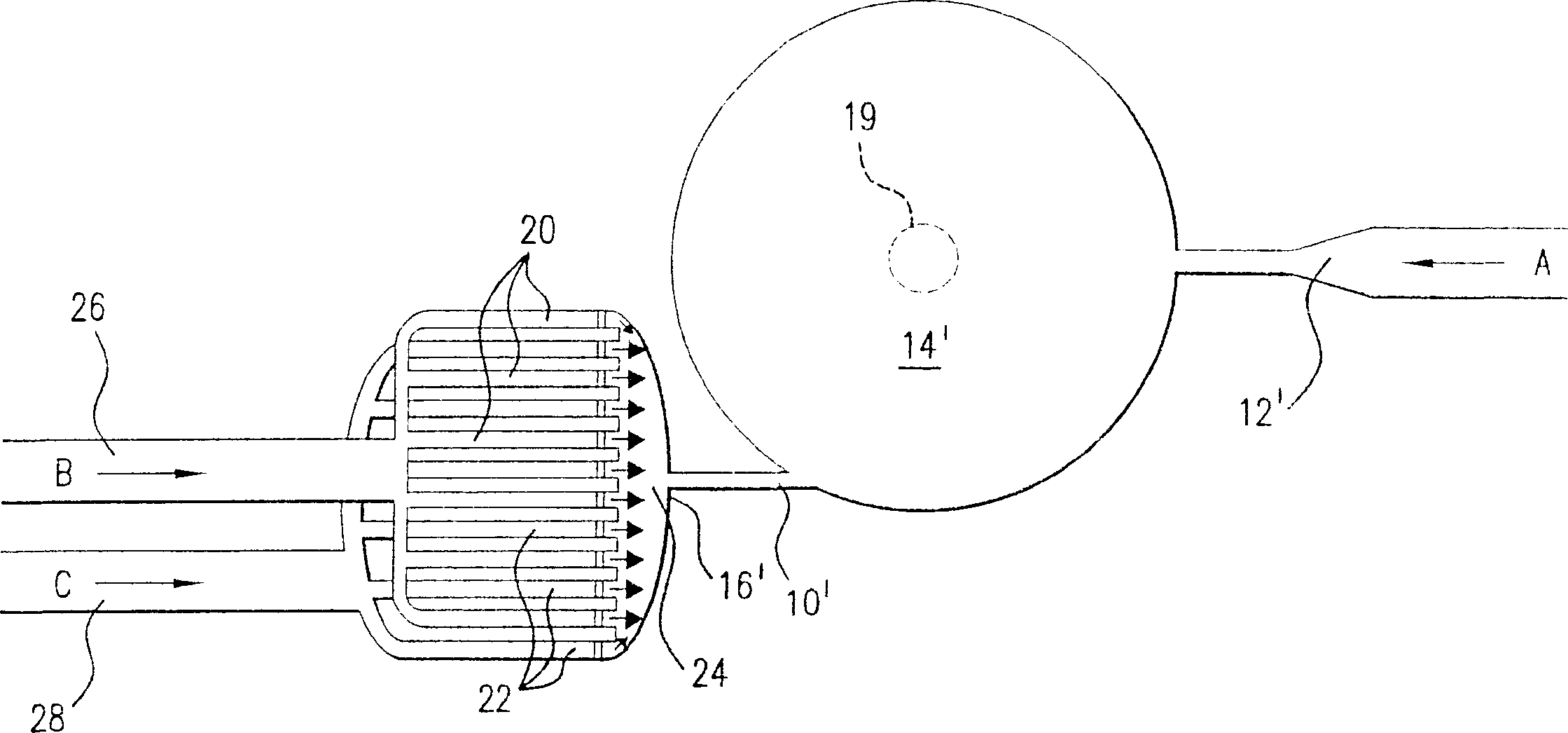

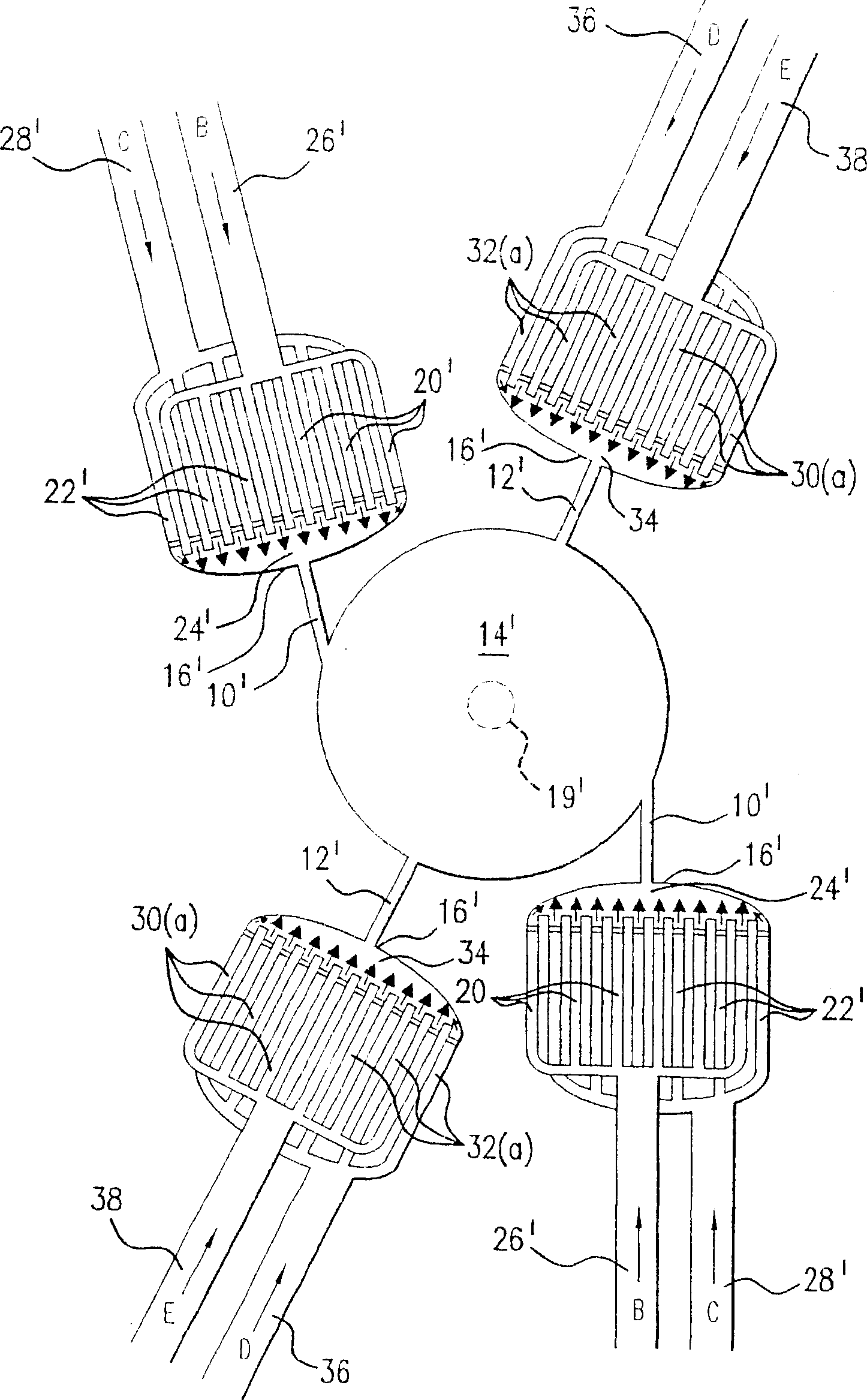

Method used

Image

Examples

Embodiment 1-5

[0074] Components comprising stacked plates were fabricated from glass and static mixers using the swirl mixing principle as already described to see if helical flow was formed under different conditions. Water and air are injected into the mixing chamber in tangential and radial directions, respectively, relative to the mixing chamber. Use a high-speed camera with digital graphics processing to see if the helical flow of the flowing liquid is formed. This can easily be determined from observing the path of the air bubbles in the water flow. The experimental results are summarized in Table 1.

[0075]

[0076] From these results, it can be seen that the desired helical flow is obtained when the liquid / gas kinetic energy ratio is 0.66 or higher. A lower limit of 0.5 is estimated for the kinetic energy ratio of fluids flowing in the tangential / radial direction. It should be noted that the much higher throughput of fluid flowing in the tangential direction can preven...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap