Method for producing joint between corrugated tube and coupling

A connecting piece and corrugated technology, applied in the field of connection generation, can solve problems such as high equipment cost, and achieve the effect of low cost, small size and compact connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

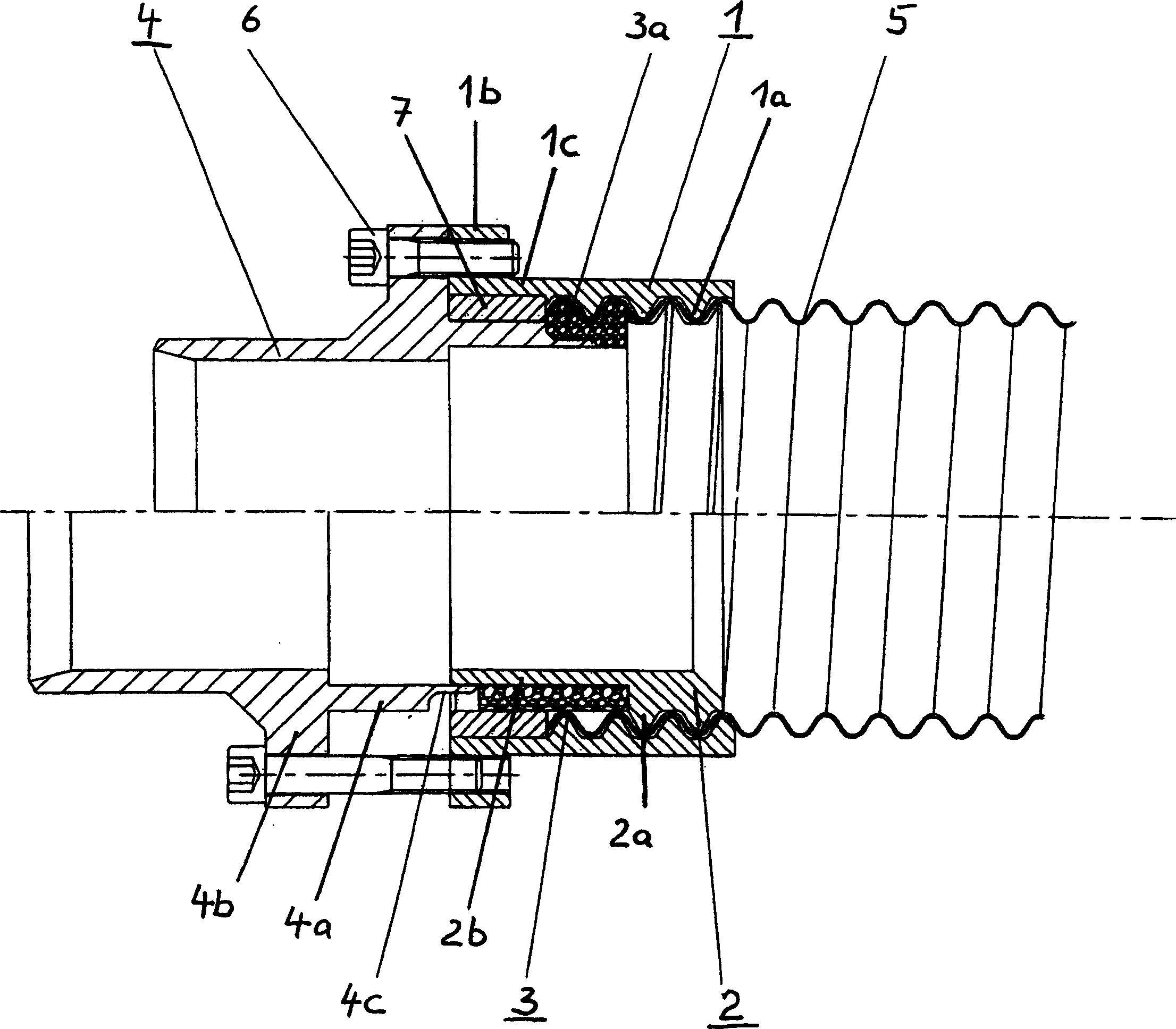

[0016] First, the support ring 2 is screwed with its coarse-pitch thread 2 a into the smooth end of the bellows 5 to such an extent that a part of the smooth wall region 2 b protrudes beyond the end of the bellows 5 . A graphite sealing ring 3 is put on the light wall part 2b, the length of this sealing ring is slightly shorter than the length of the light wall part 2b.

[0017] A compression ring 1 is screwed onto the bellows 5 by means of its coarse-pitch thread 1 a such that the last thread ends at the end of the bellows 5 and the bare area 1 c extends beyond the end of the bellows.

[0018] A metal pipe 7 is arranged on the sealing ring 3 .

[0019] The connecting part 4 has a projection 4a, which can be slid into the annular gap between the bellows 5 and the bare wall portion 2b.

[0020] The flanges 4 b , 1 b are brought closer to each other by means of fastening screws 6 , which are passed through holes, not shown in detail, in the flange 4 b of the connecting part 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com