Heat separating structure for gas burning radiation roaster

An oven, gas technology, applied in the field of other parts of the oven, can solve the problems of safety, lack of economy, etc., and achieve the effect of preventing safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

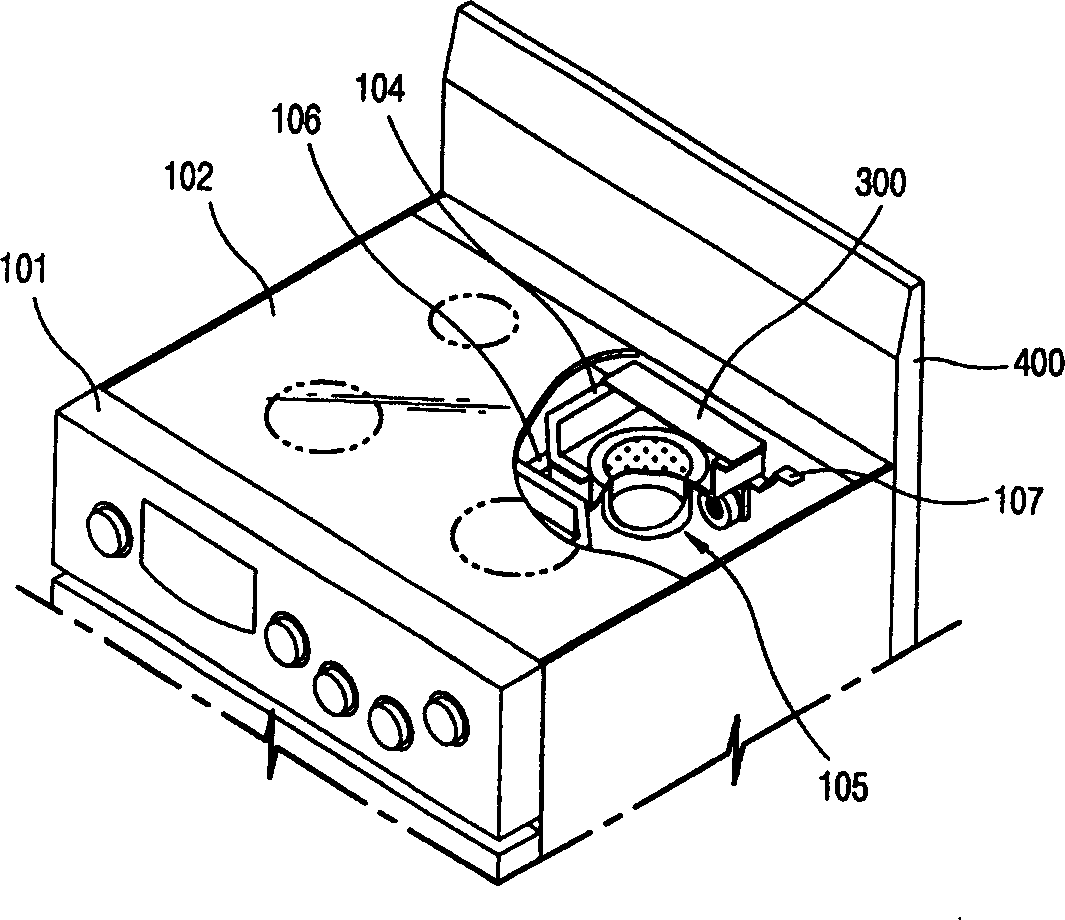

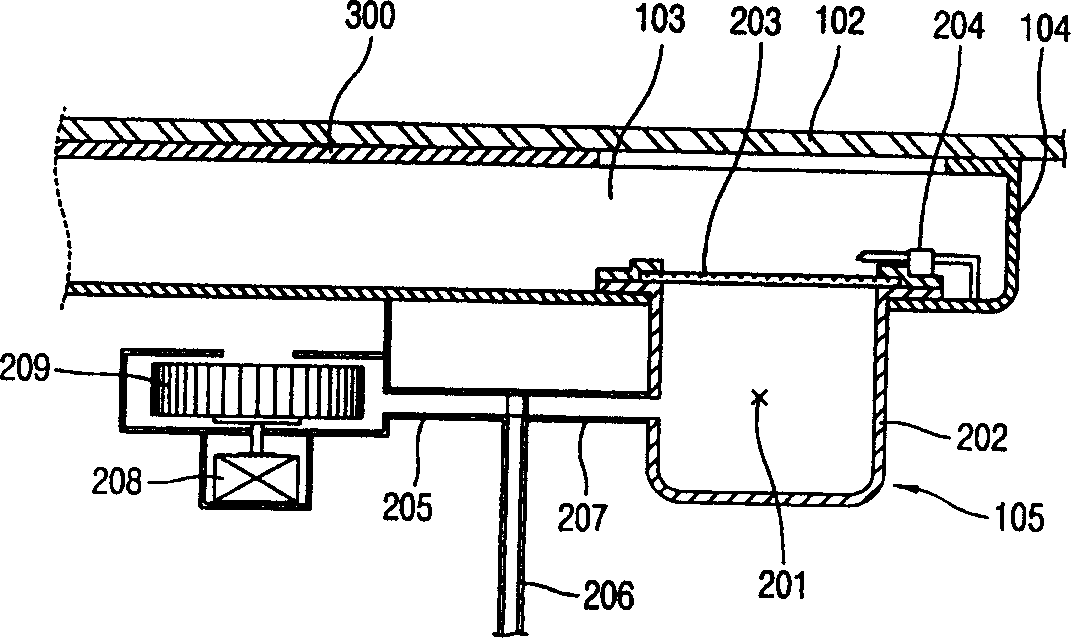

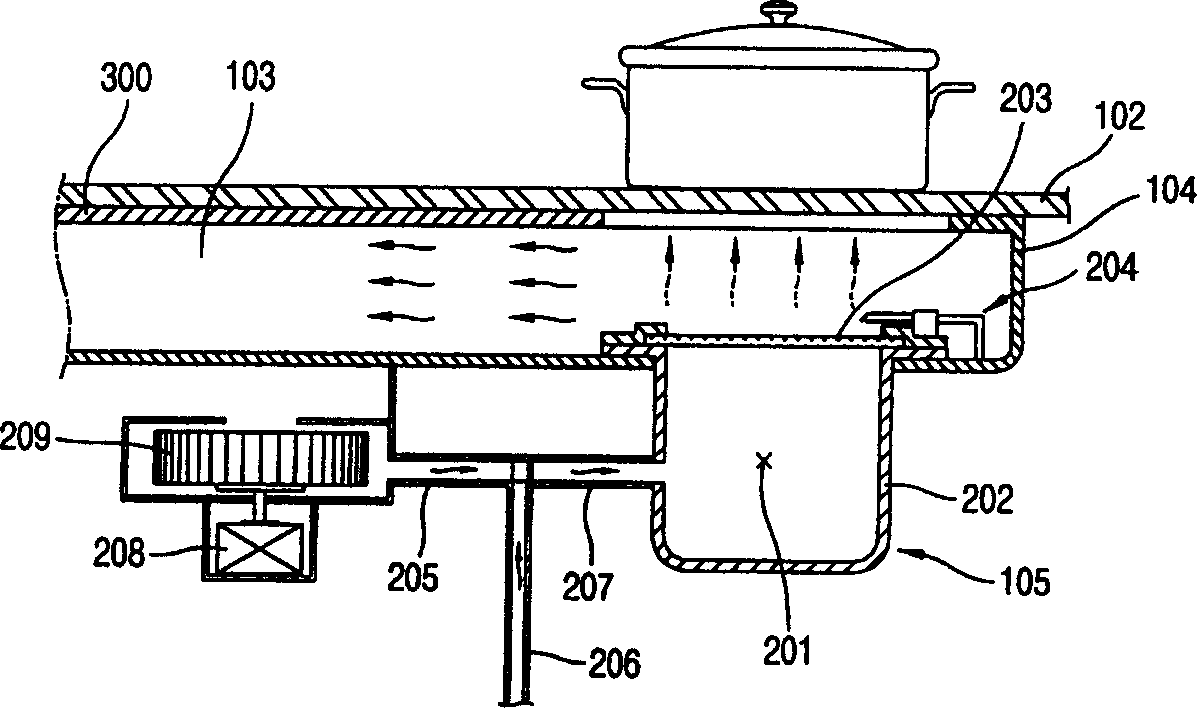

[0020] Below, with reference to the heat insulation structure experiment diagram of the gas radiation oven of the present invention having the above structure, the present invention is described in detail, as shown in the figure, the gas radiation oven with the heat insulation structure of the present invention is opened from the upper side, A shell (101) with a certain space; a ceramic glass (102) that covers the opening on the upper side of the shell (101) and can be placed for cooking; A plurality of burner sleeves (104) connected to form an exhaust passage (103) between them; respectively connected to the burner sleeves (104) to burn the mixed gas and generate radiation waves (105) ; In order to communicate with the above-mentioned exhaust channel (103), it is arranged on the lower side of the burner casing (104), and the exhaust gas is discharged to the rear part (400) The exhaust hole (106); the above-mentioned exhaust tube (106) is fixed ) and the burner bushing (104) c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com