Manufacturing method of semiconductor device and oxidization method of semiconductor substrate

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as not pointing out the oxide film, not describing the conditions of the oxide film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

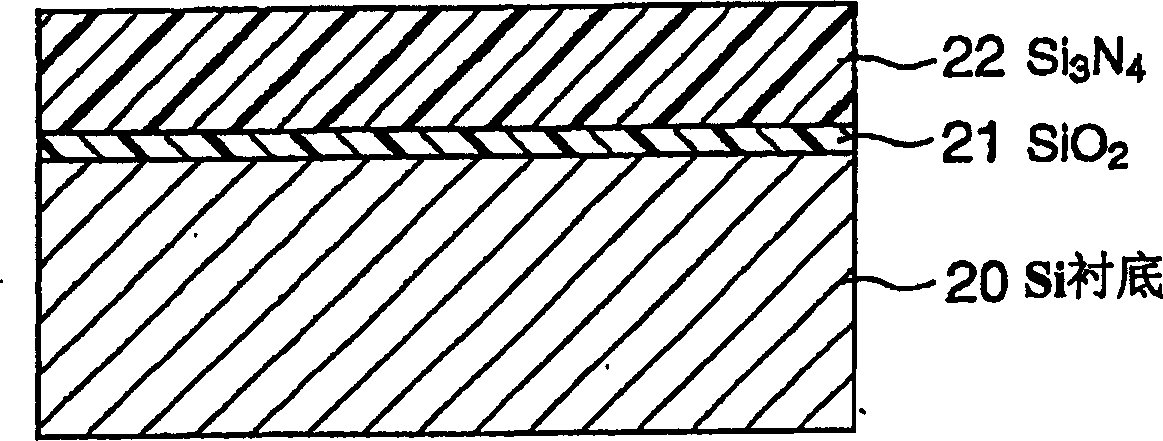

[0039] refer to Figure 1 to Figure 7 , a method for manufacturing a semiconductor device according to an embodiment of the present invention is described step by step. Here, as an example, the manufacture of a DRAM as a semiconductor device will be described. refer to figure 1 , a silicon oxide film 21 and a silicon nitride film 22 are sequentially formed on a silicon substrate 20 by ordinary techniques.

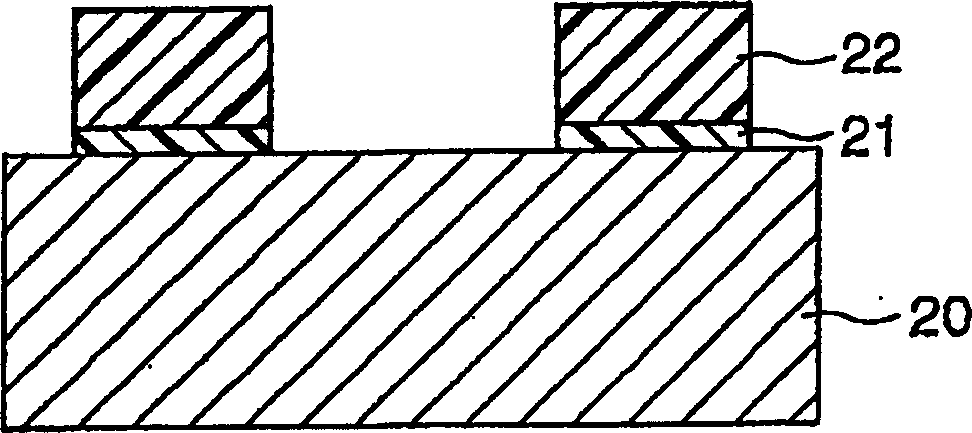

[0040] Next, if figure 2 As shown, after the region where the groove is to be formed is covered by a mask (not shown), the silicon nitride film 22 and the silicon oxide film 21 are selectively etched using photolithography and dry etching techniques, and the silicon substrate Only silicon nitride film 22 and silicon oxide film 21 in the element region remain on substrate 20, and the surface of silicon substrate 20 is divided into an element region and a region for groove formation.

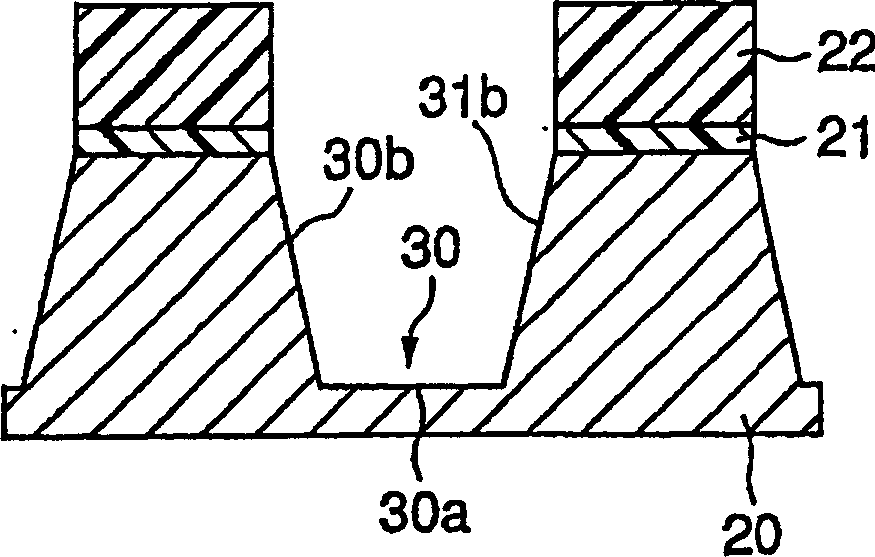

[0041] In this case, as image 3 As shown, the silicon oxide film 21 and the silicon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com