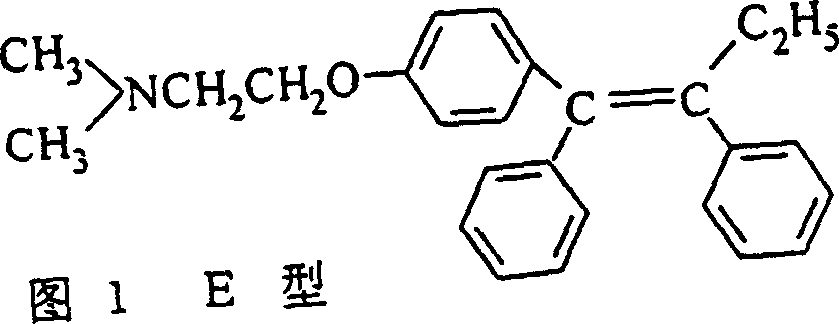

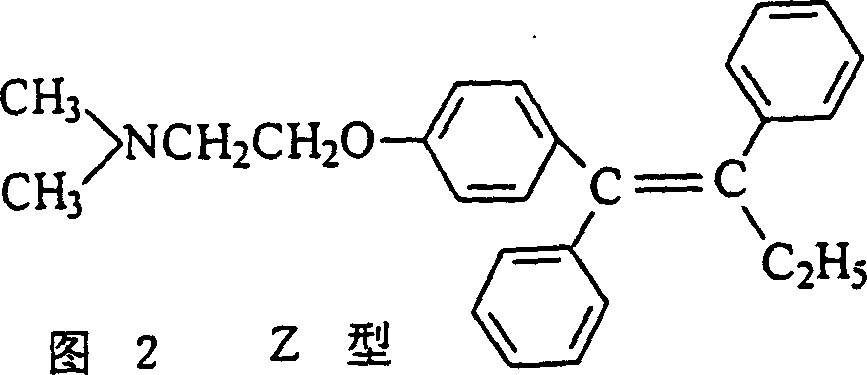

Process for preparing high purity low E type Tamoxifen citrate

A technology of tamoxifen and citrate, applied in the field of chemical pharmaceutical industry, can solve the problems of difficult production of high-purity and low-E-type tamoxifen, high-purity and low, and achieve low cost, relatively efficient separation process short process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 10 grams of tamoxifen, the content of the E-isomer is 1.8%. Add it into 200 ml of 0.05% sulfuric acid, heat and stir to dissolve; cool to room temperature, and filter to obtain tamoxifen sulfate with increased Z-isomer content.

[0032] Neutralize with alkali to obtain 8 grams of tamoxifen. Tested according to the method specified in the British Pharmacopoeia (98 edition), the content of the E-isomer is 0.02%.

Embodiment 2

[0034] 10 grams of tamoxifen, the content of the E-isomer is 2.1%. Add it into 200 ml of 1% sulfuric acid, heat and stir to dissolve; cool to room temperature, and filter to obtain tamoxifen sulfate with increased Z-isomer content.

[0035] Neutralize with alkali to obtain 6.8 g of tamoxifen. Tested according to the method specified in the British Pharmacopoeia (98 edition), the content of the E-isomer is 0.01%.

Embodiment 3

[0037] 10 grams of tamoxifen, the content of the E-isomer is 1.5%. Add it into 100 ml of 0.5% hydrochloric acid, heat and stir to dissolve; cool to room temperature, and filter to obtain tamoxifen sulfate with increased Z-isomer content.

[0038] Neutralize with alkali to obtain 7.5 g of tamoxifen. Tested according to the method specified in the British Pharmacopoeia (98 edition), the content of the E-isomer is 0.03%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com