Liquid hydrogen fuel carrying and heat exchanging system of hydrogenfuel high speed airplane

A liquid hydrogen, high-speed technology, applied in the field of aircraft, can solve the problems of aero-engines that do not have high-power, non-polluting portable power sources, limited calorific value per unit mass, and cannot be implemented, and achieve significant economic and social benefits. The effect of alleviating energy shortage and eliminating air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

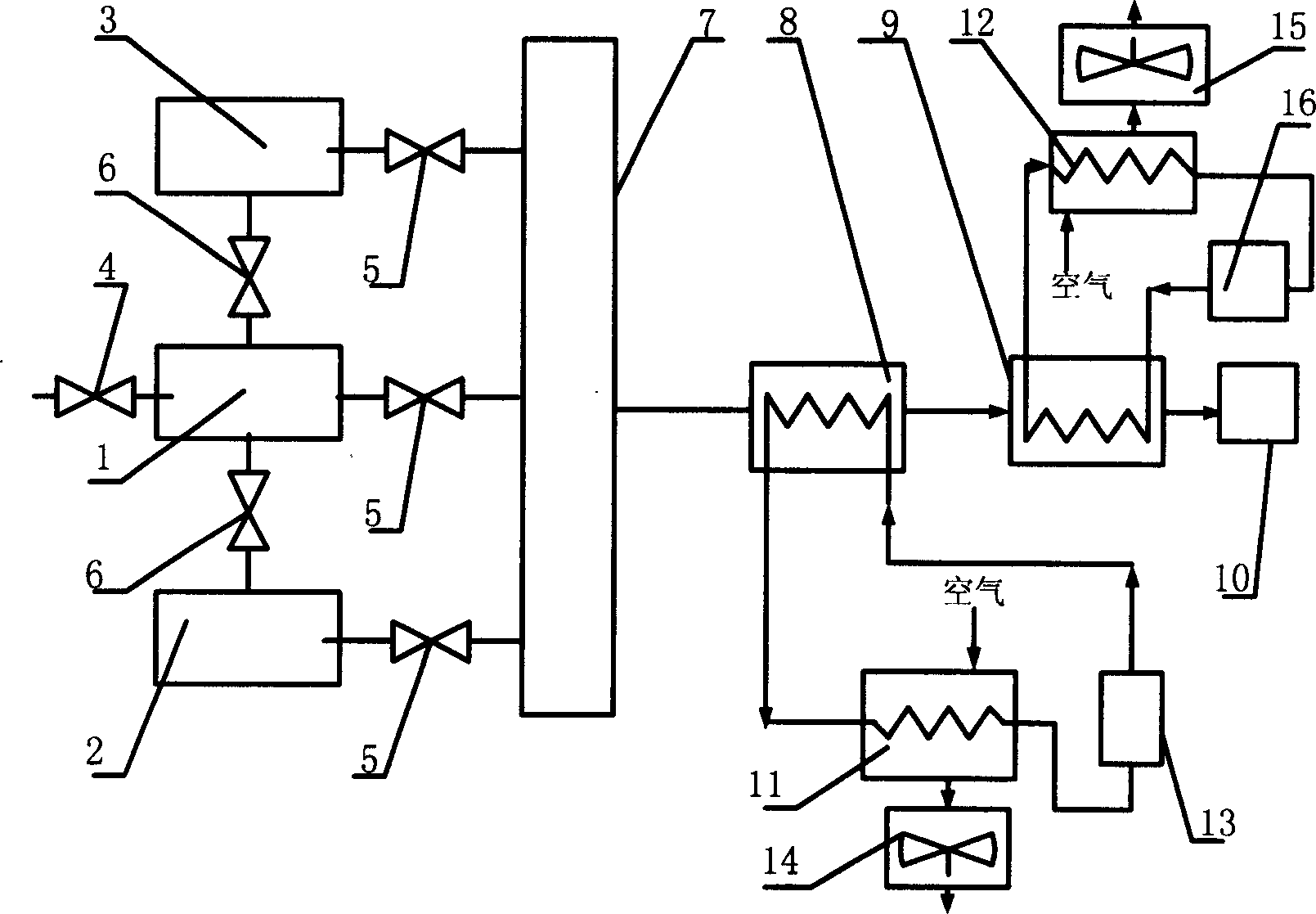

[0009] Such as figure 1 As shown, the present invention mainly includes: main liquid hydrogen storage tank 1, wing liquid hydrogen storage tank group 2, fuselage liquid hydrogen storage tank group 3, stop valves 4, 5, 6, liquid hydrogen main pipe 7, first evaporator 8. Second evaporator 9, engine combustion chamber 10, hydraulic oil heat exchanger 11, lubricating oil heat exchanger 12, hydraulic system 13, fans 14, 15, lubrication system 16.

[0010] The main liquid hydrogen storage tank 1 is placed in the fuel tank of the aircraft, the wing liquid hydrogen storage tank group 2 and the fuselage liquid hydrogen storage tank group 3 are a group of boxes made according to the shape of the wing and the fuselage respectively, and are placed in Inside the wings and fuselage. The wing liquid hydrogen storage tank group 2 and the fuselage liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com