Sidelight type aphototropism module and liquid crystal display device

A liquid crystal display device and backlight module technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of complex assembly structure, light leakage, material waste, etc., and achieve the effect of simplifying assembly and simplifying the complexity of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

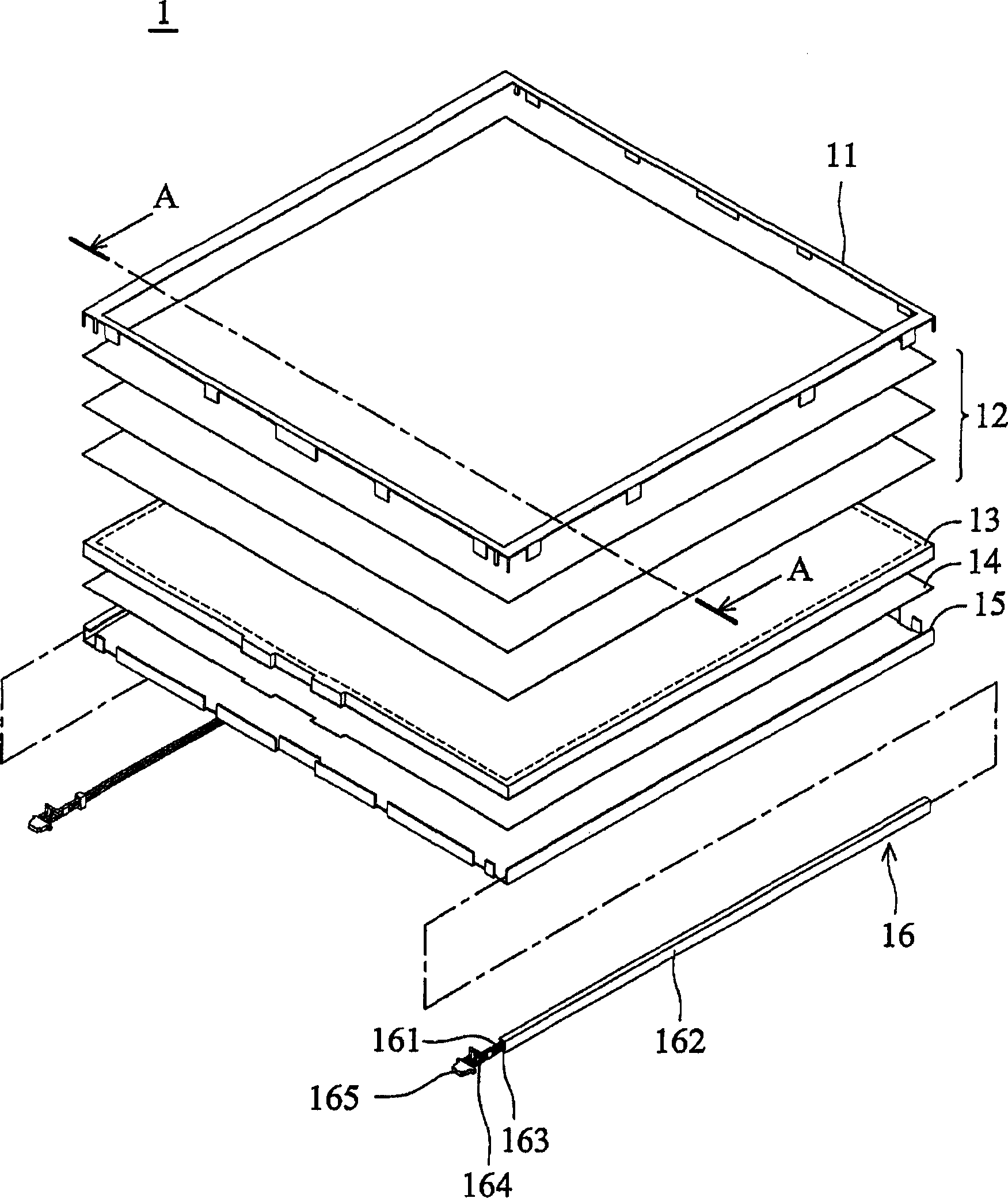

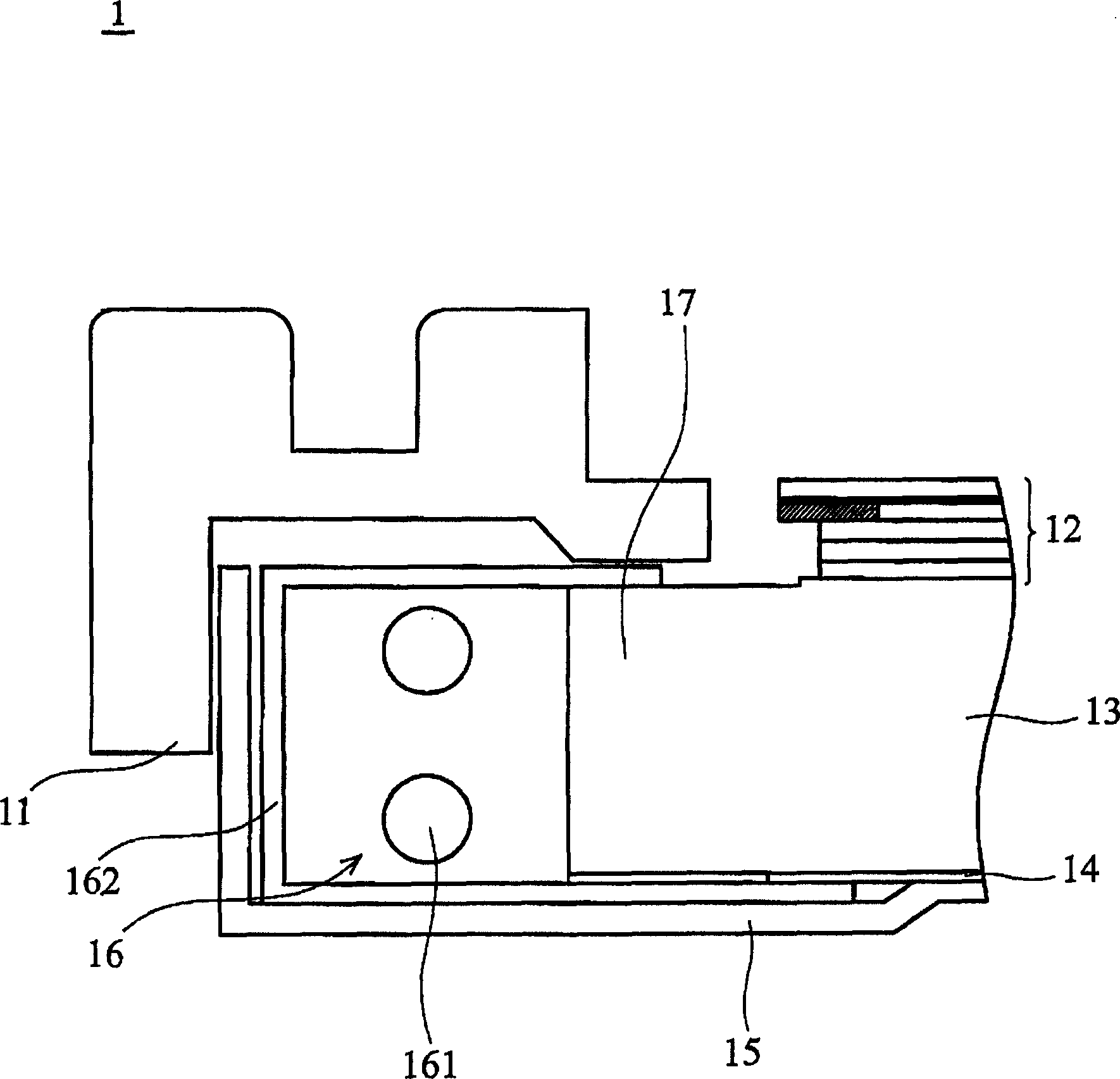

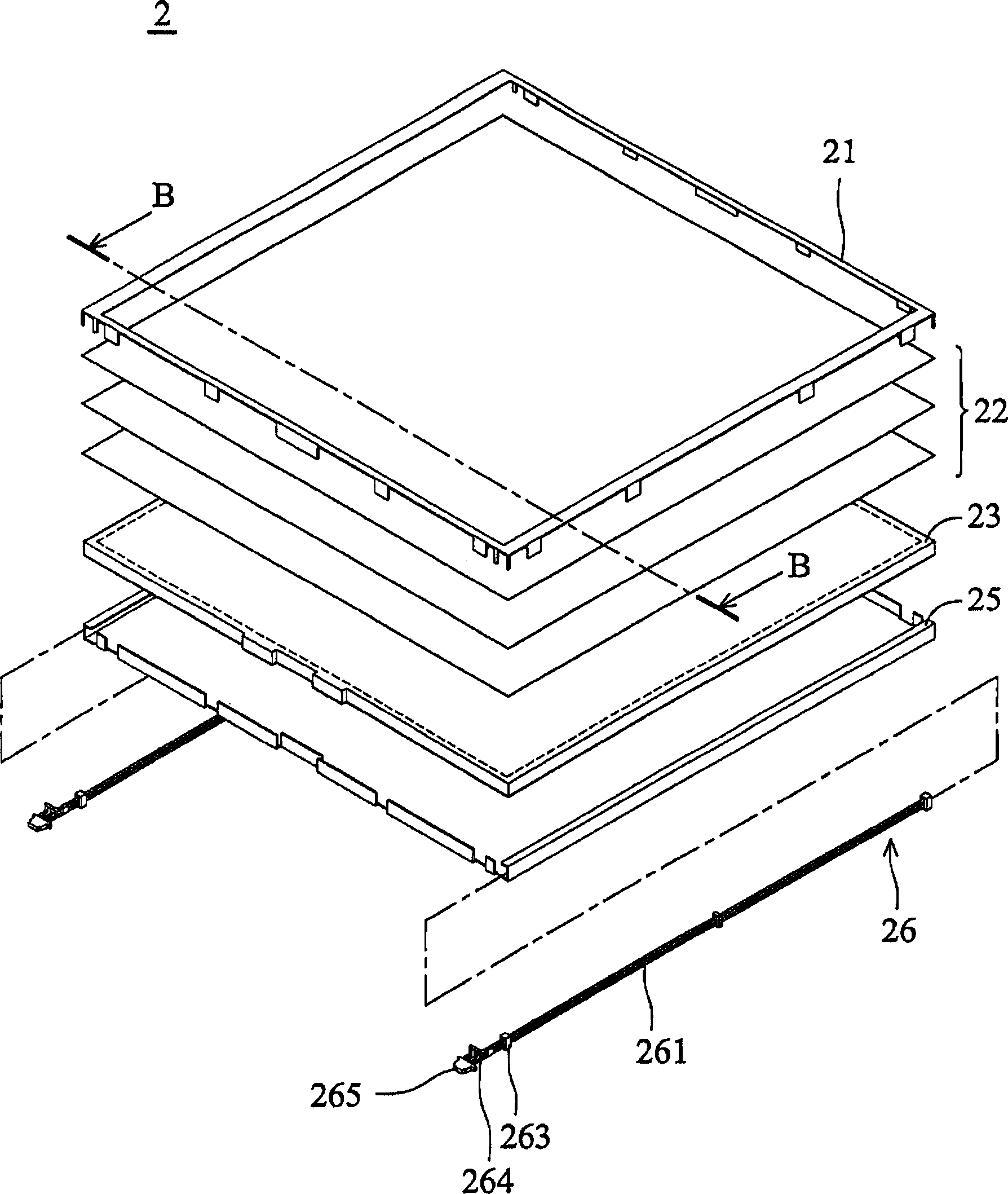

[0015] See image 3 , using an embodiment to illustrate the edge-lit backlight module 2 of the present invention. The edge-lit backlight module 2 of this embodiment is composed of a frame 21 , a light-diffusing device group 22 , a light guide plate 23 , a reflective backplane 25 and light source groups 26 arranged on both sides. The edge type backlight module 2 of this embodiment and figure 1 The difference of the shown existing edge-lit backlight module 1 is that the existing edge-lit backlight module 1 separates the reflective sheet 14 from the back plate 15, while the edge-lit backlight module 2 of this embodiment separates the reflective sheet and the backplane 15. The functions of the backboard are combined into one, and exist in the form of a reflective backplane 25 . As for other components, they are the same as the existing edge-lit backlight modules, for example, the light source group 26 is provided with a lamp tube 161 as a light source, a light source group refle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com