High performance self-regulating roational flow type gas liquid separator

A liquid separator and self-adjusting technology, which is applied in the direction of swirling devices and devices whose axial direction can be reversed, can solve the problems of granular sludge crushing, low work efficiency, and increasing the gas content of reflux, and achieve Low cost, simple structure, no effect of moving parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

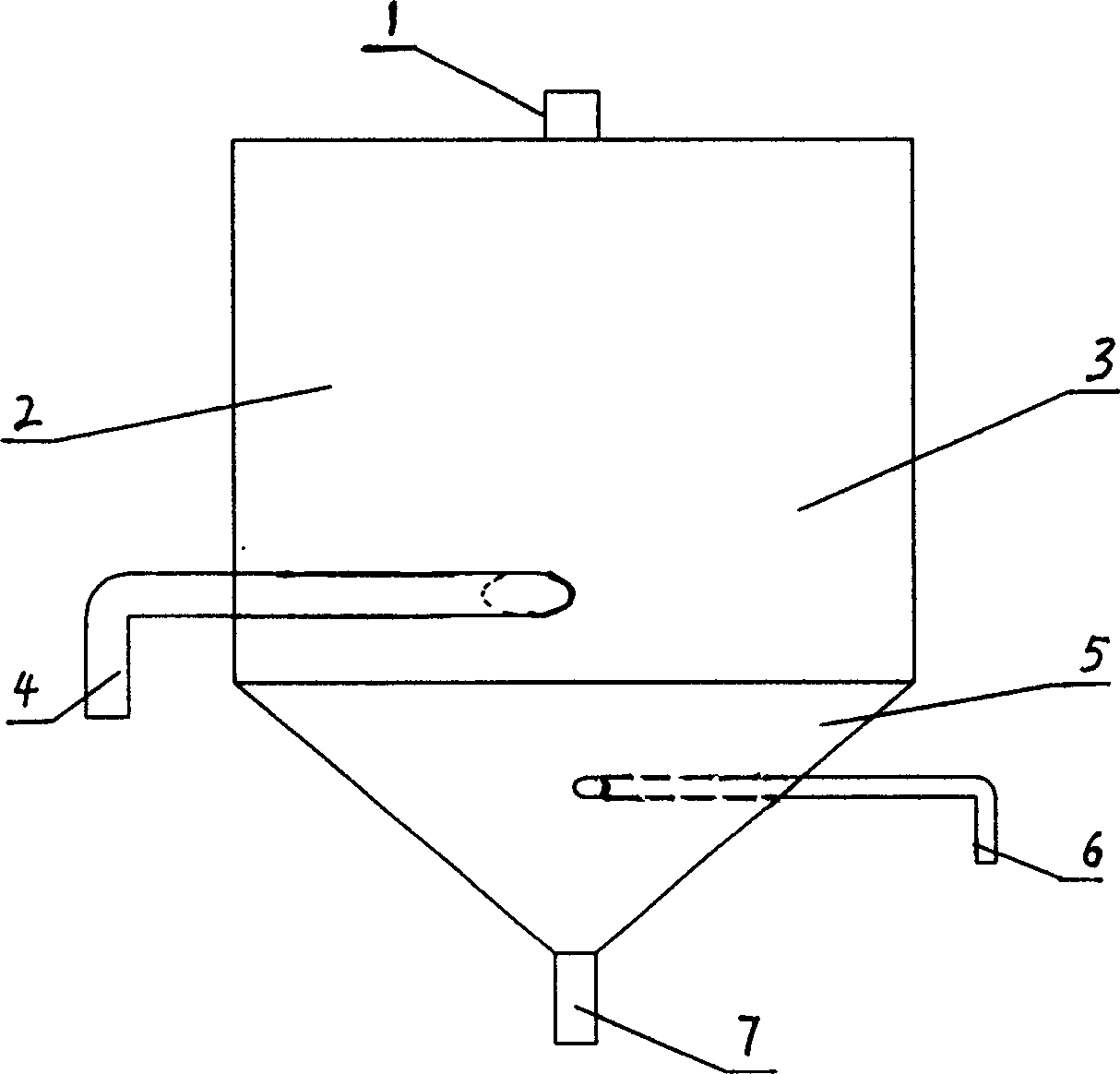

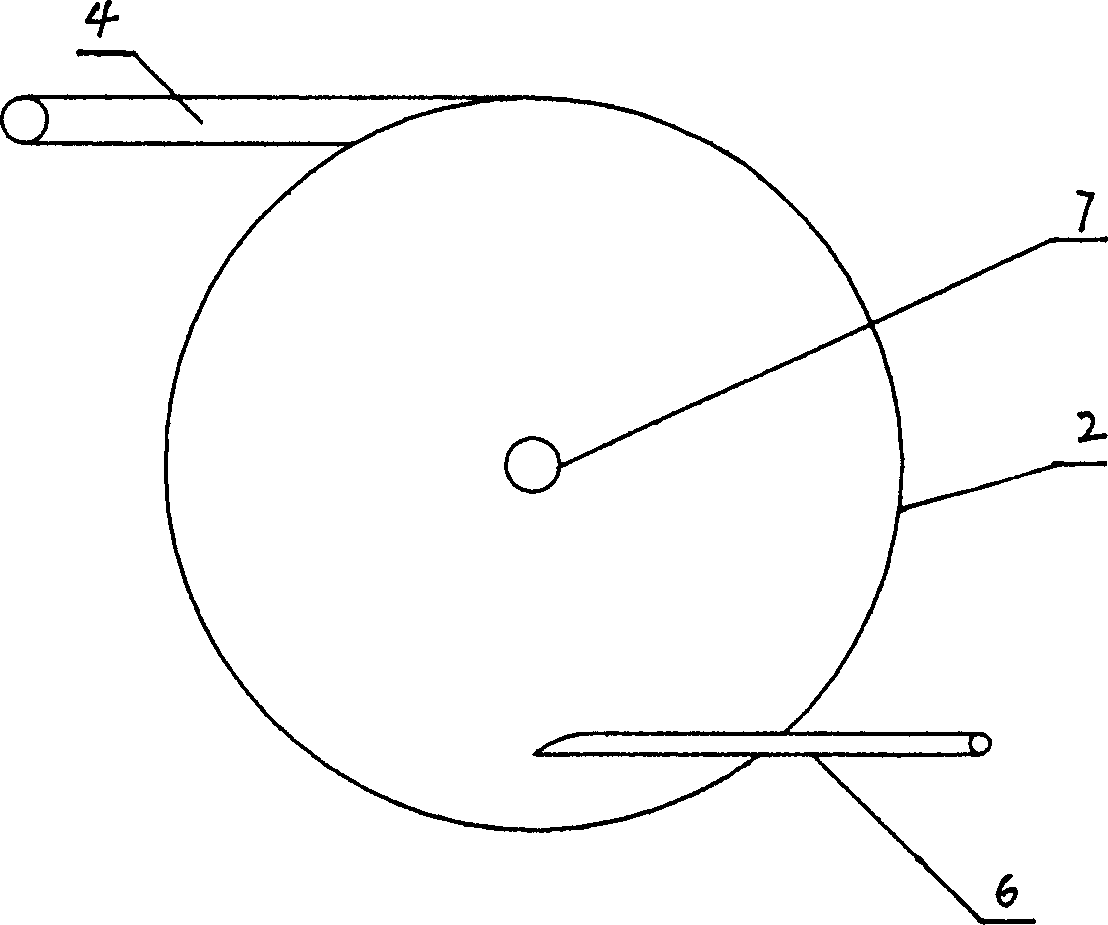

[0019] The present invention consists of a separator housing 2, a water inlet pipe, an outlet pipe 7 and a biogas conduit 1. The separator housing 2 is composed of a cylindrical upper housing 3 and a conical lower housing 5. The biogas The conduit 5 is installed on the central top of the upper casing 3 , and the water outlet pipe 7 is installed on the bottom of the lower casing 5 . The shape of the lower casing 5 is conical with a cone angle of 60° to 90°.

[0020] The water inlet pipe is composed of the main riser 4 and the starting auxiliary riser 6. The main riser 4 enters the inner wall of the cylindrical upper shell 3 along the tangential direction perpendicular to the central axis and sticks to the inner wall of the upper shell 3 side. The riser tube 6 enters the inner wall of the lower housing 5 along the tangenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com