Slide core unit

A core mold and mold technology, which is applied in the field of sliding core mold devices, can solve the problems of increased maintenance cost of a forming metal mold 1, and achieve the effects of reduced maintenance cost and simplified structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

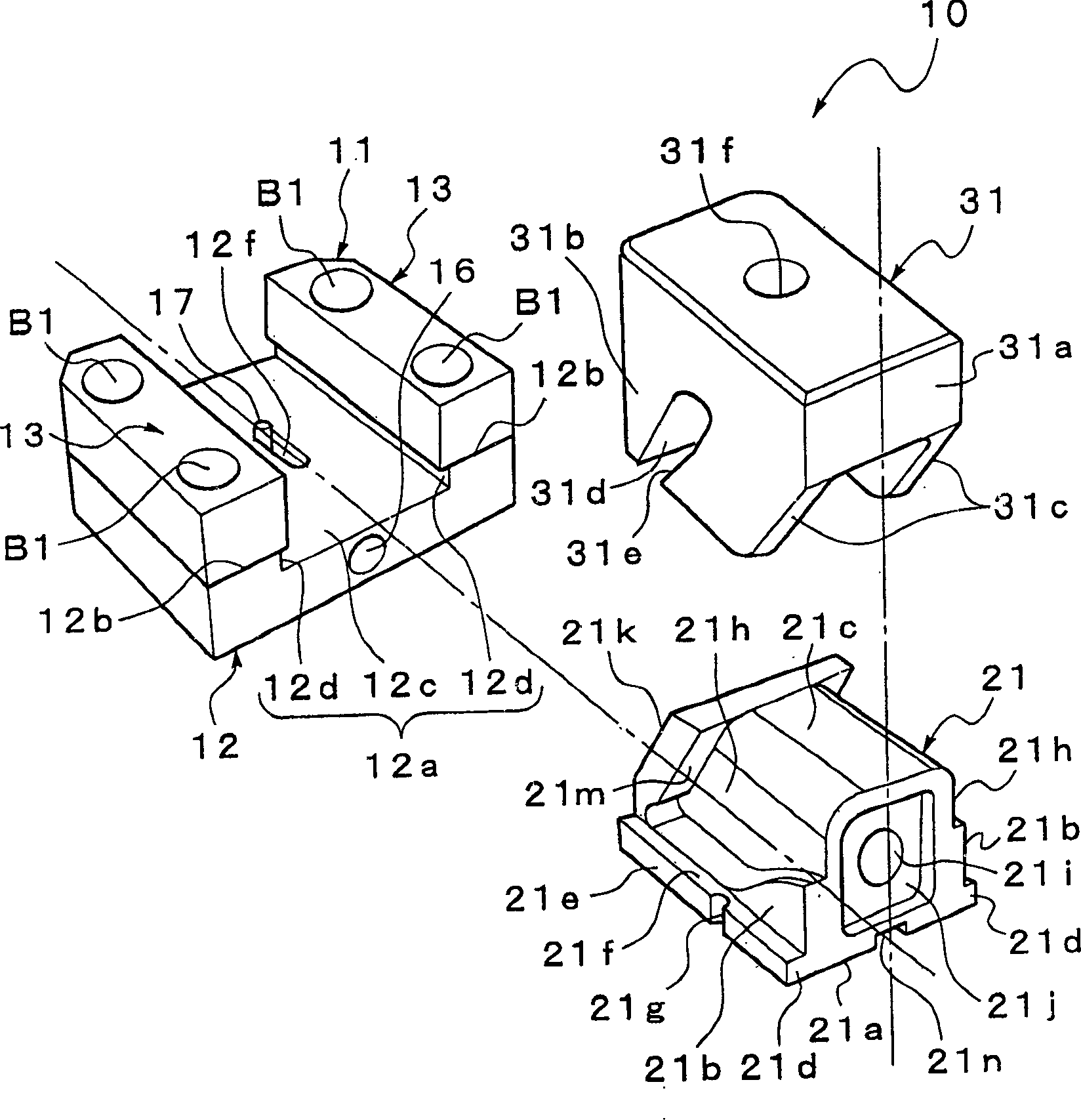

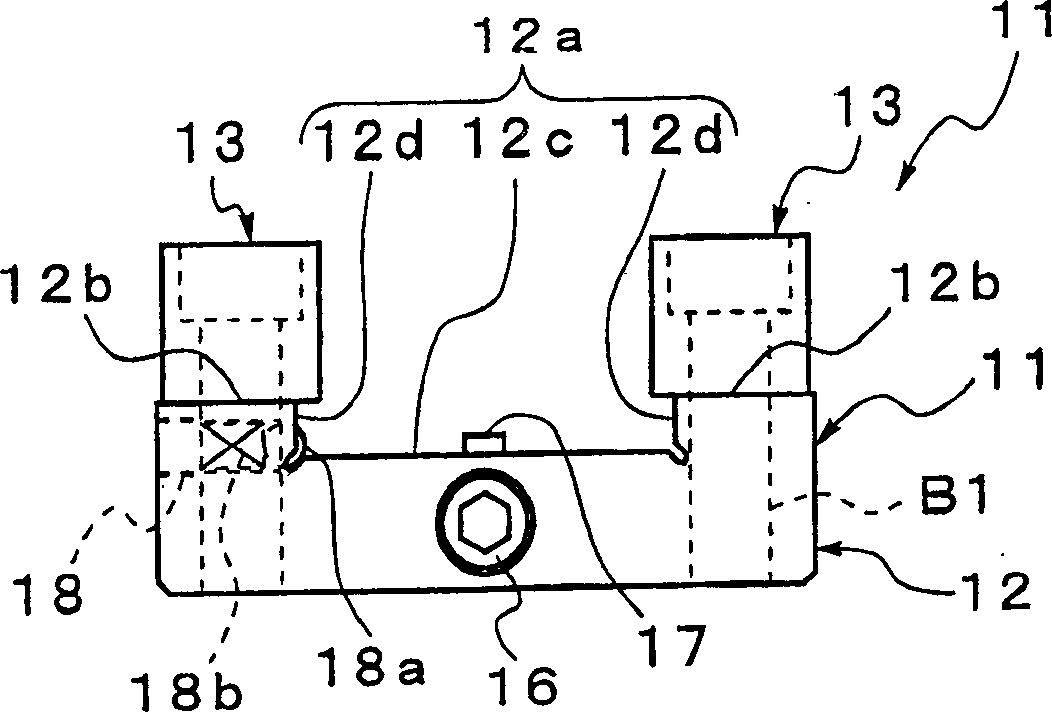

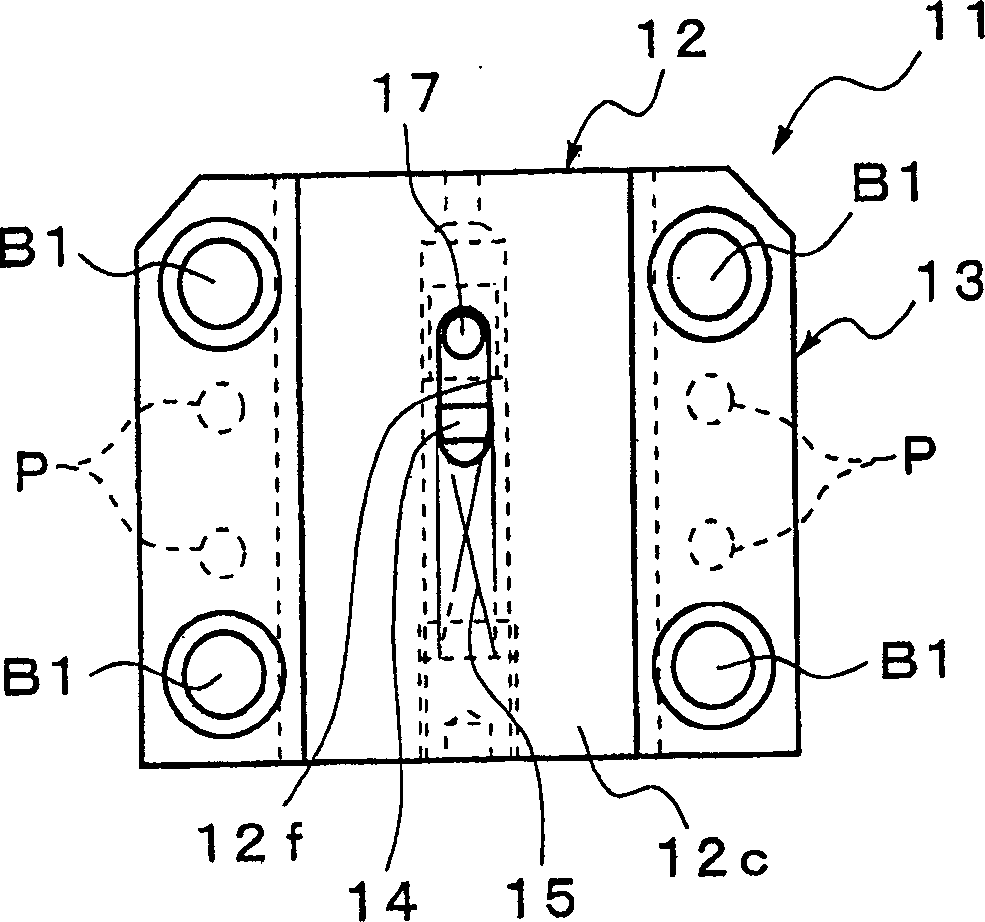

[0050] First, refer to Figure 1 to Figure 9 The first embodiment will be described. However, the same symbols are assigned to the same components as those in the prior art example, and the description thereof will be simplified.

[0051] Such as Figure 8 and Figure 9 As shown, the slide core mold device 10 shown in this embodiment is set in the forming metal mold 8 . The molding metal mold 8 has a pair of molds, that is, a fixed mold 6 and a movable mold 7 that are freely openable and closed, and these fixed molds 6 and movable molds 7 are respectively fixed to fixed plates of an injection molding machine (not shown). and movable disk. The injection molding machine drives the movable mold 7 in the opening and closing direction by moving the movable platen in the forward and backward direction relative to the fixed platen.

[0052] In addition, if Figure 8 As shown, when the molding metal mold 8 is in the mold-closed state, the mating surfaces 6a, 7a of the fixed mold...

no. 2 Embodiment approach

[0085] Next, refer to Figure 12 ~ Figure 1 6b to describe the second embodiment of the present invention. However, the same reference numerals are given to the same components as those of the first embodiment, and the description thereof will be simplified.

[0086] The sliding core device 10A shown in this embodiment has a configuration in which a sliding core 21A is provided with an urging mechanism that acts on the sliding core 21A in a direction retreating from the chamber 8a with respect to the guide member 11A. Apply force.

[0087] Such as Figure 12 , Figure 13a and Figure 13b As shown, the guide member 11A is formed in the shape of a square rod, and a groove-shaped rail portion 11 b linearly extending in the axial direction is formed on an upper surface 11 a of one side thereof. The rail portion 11b has inner surfaces 11d vertically standing up from both ends in the width direction of the planar bottom surface 11c, and sections protruding inward from each othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com