Pile-soil action indoor testing apparatus

A technology of test device and action chamber, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., to achieve good repeatability, facilitate the correction of test results, and eliminate the effects of initial displacement system errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

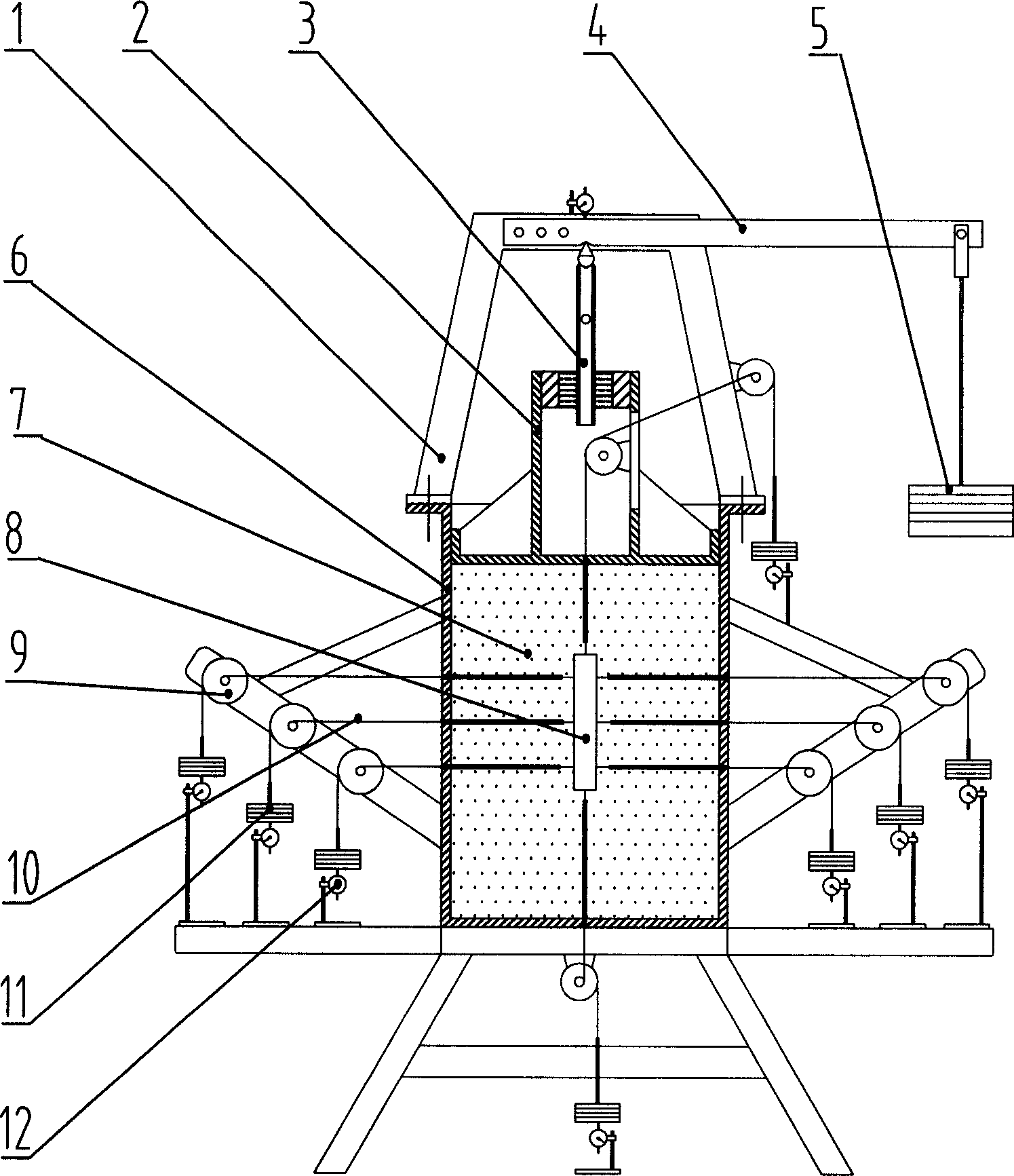

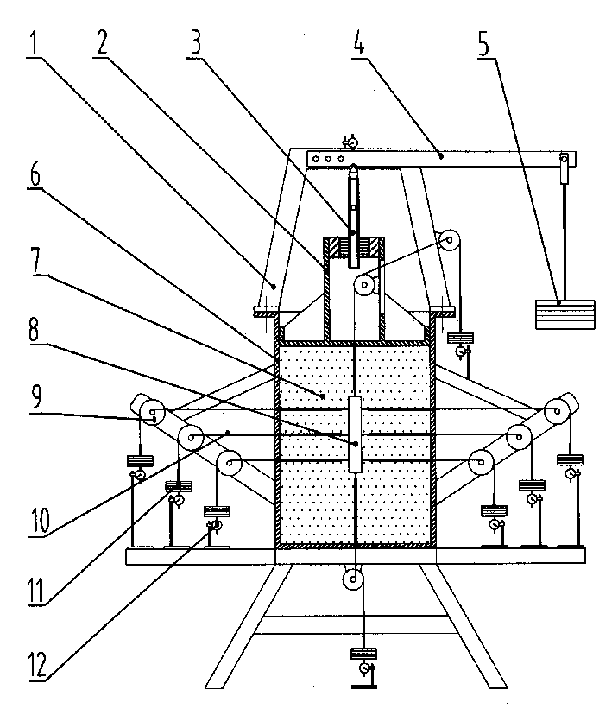

[0016] Now in conjunction with the accompanying drawings of the description, the present invention will be further described:

[0017] (1) Manufacture the overlying earth pressure ballast system, bucket body, and loading system of the device according to the design requirements, and complete the device.

[0018] (2) Connect the model pile to the casing (the one that needs to go through the ballast cover is only connected to the pile first), and apply lateral force in a balanced manner.

[0019] (3) Put the test foundation soil into the barrel and pre-bury the model piles (usually the diameter of the pile is not greater than 1 / 6 of the inner diameter of the barrel, and the thickness of the soil at the top and bottom of the pile is not less than 5 times the diameter of the pile). The overburden pressure ballast system is installed, and the vertical force is applied to the model pile in balance through the set of wires.

[0020] (4) Refer to the geotechnical consolidation test p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com