Multi-cavity conjoined chamber unaerated elastic burst-proof tyre

An explosion-proof tire and conjoined technology, which is applied to non-pneumatic tires, highly elastic wheels, tire parts, etc., can solve the problems of high production cost, small load capacity, and not been widely promoted and used, and achieves low use cost and elimination of The effect of the hidden danger of an accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

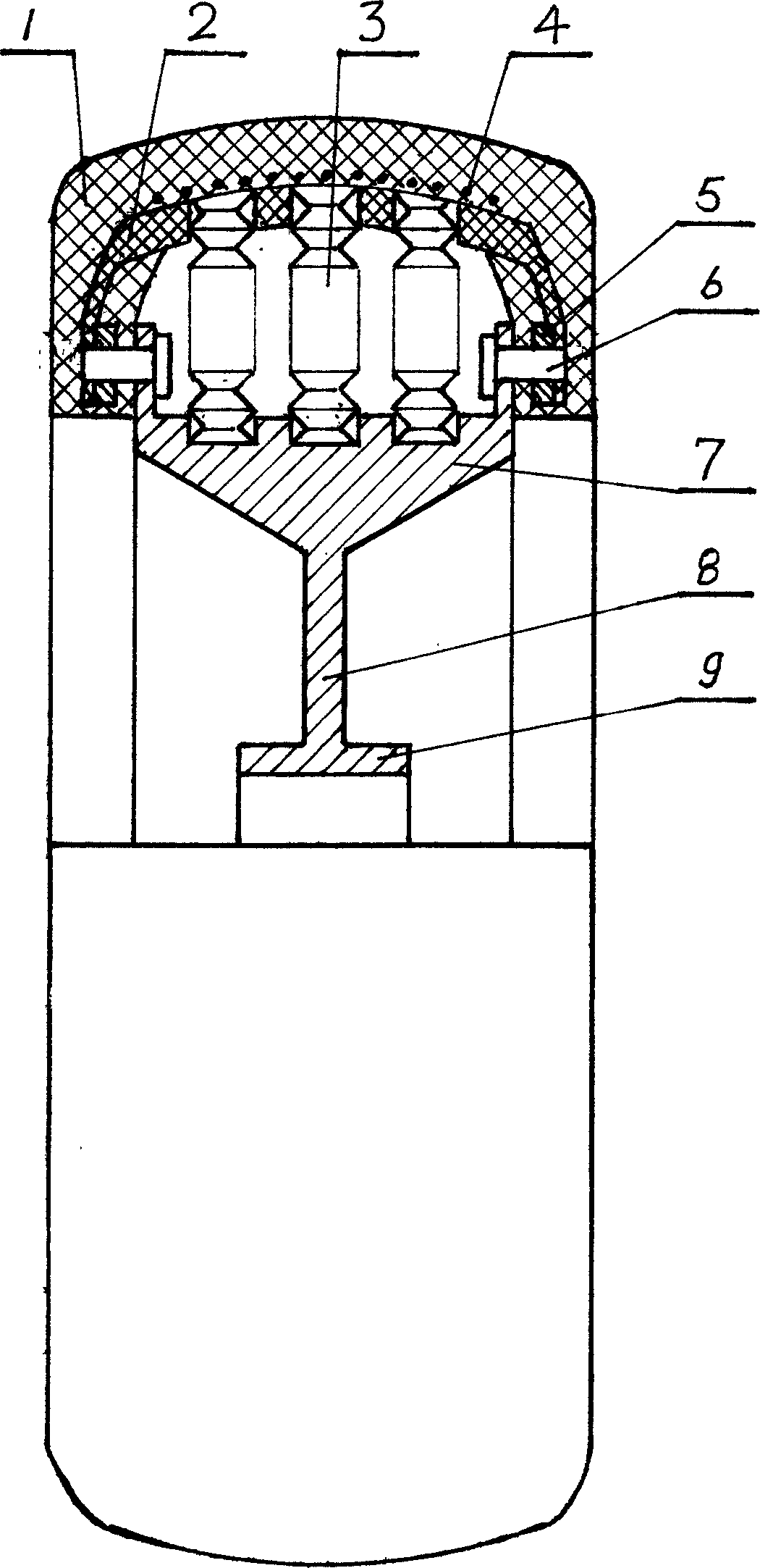

[0017] Such as figure 1 As shown, a spoke [8] is fixedly connected to the inner surface of the steel ring [7], and a wheel hub [9] is fixedly connected to the spoke [8]. The hub [9] is used to connect with the axle, and the steel ring [7] The section is "U" shaped, and there are 3 grooves at the bottom of the "U" shape of the steel ring [7]. One end of the compression spring [3] is stuck in the groove of the steel ring [7], and the steel ring [7] The bolt [6] forms a detachable connection with the tire [1]. The cross-section of the tire [1] is an inverted "U" shape matching the cross-section of the steel ring [7]. The tire [1] is composed of meridians and rubber. A compression gasket [5] made of hard material is designed in the two vertical arms of the "U" shape. The compression gasket [5] is circular and has a bolt hole on it. In this bolt hole, the reliable connection between the cover tire [1] and the steel ring [7] can be ensured, and the elastic ring [4] made of elastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com