Single-chamber osmotic pump controlled release tablet containing pregabalin

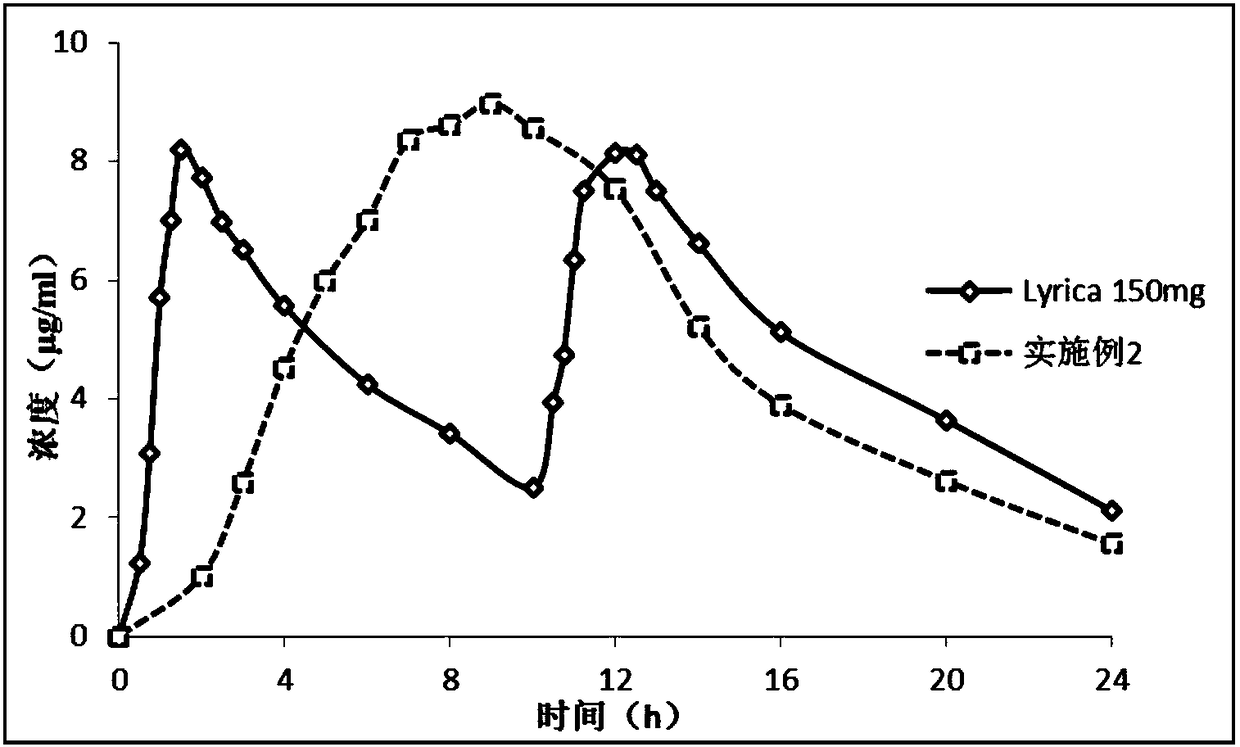

A single-chamber osmotic pump and pregabalin technology, applied in the field of pharmaceutical preparations, can solve the problems of ionic group compatibility risk, process scale-up risk, performance impact, etc., to reduce the number of medications, improve compliance and effective The effect of reducing the peak and valley effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] prescription:

[0027] I chip

[0028]

[0029] II controlled release film coat

[0030]

[0031] Preparation Process:

[0032] Mixing: pass pregabalin, mannitol and hydroxypropyl cellulose through a 30-mesh sieve to remove lumps, and mix them in a material mixer for 20 minutes after treatment; pass magnesium stearate through a 30-mesh sieve and then mix with pregabalin powder for 3 The final blend was obtained after 1 min.

[0033] Tablet compression: the blended pregabalin powder is directly compressed with a circular shallow concave punch and a rotary tablet press to control the tablet hardness to 10-20kg.

[0034] Seal coating (optional): A layer of water-soluble seal coating can be coated between the tablet core and the controlled-release film coat, and the coating powder 03A19322-CN is transparent and soluble in pure water. Use a high-efficiency coating pan to coat the tablet core with a sealing layer. The atomization pressure is 0.1-0.2MPa, the tablet ...

Embodiment 2

[0038] prescription:

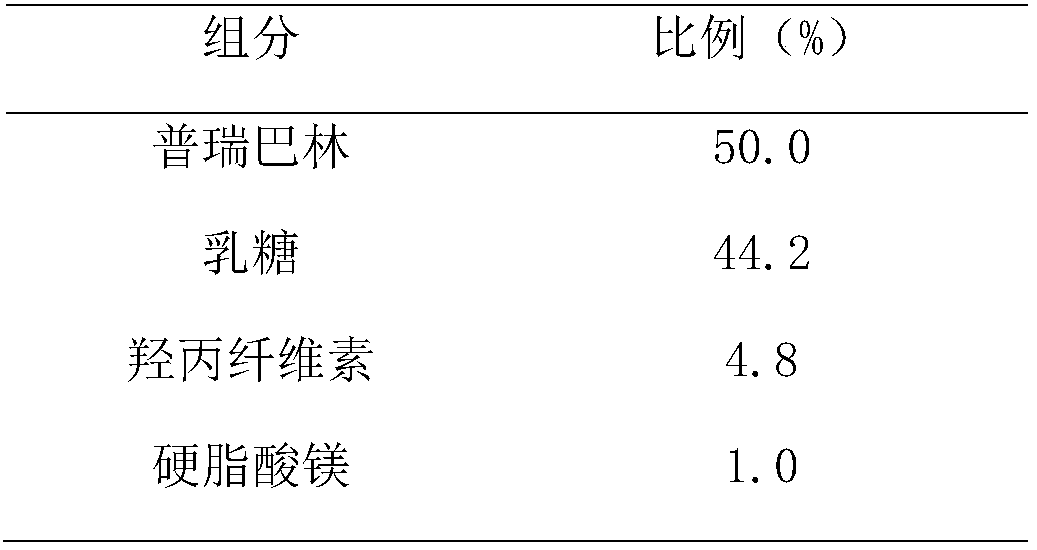

[0039] I chip

[0040]

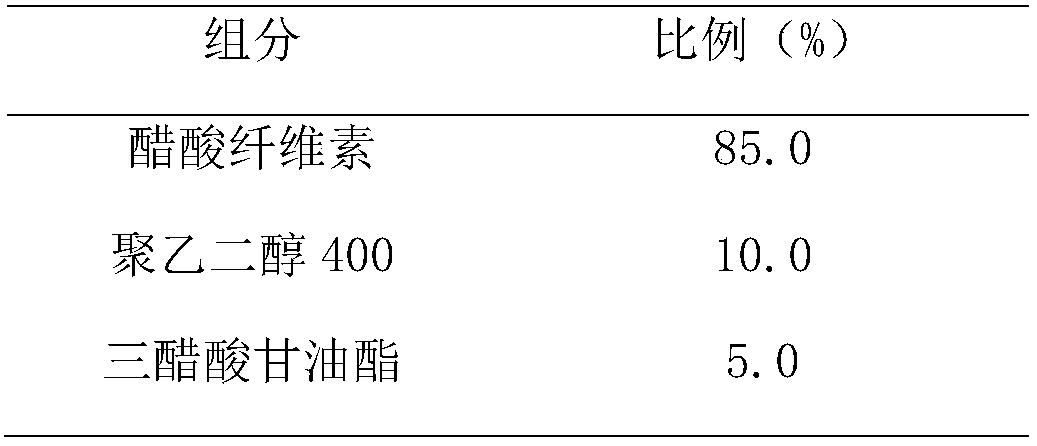

[0041] II controlled release film coat

[0042]

[0043] Preparation Process:

[0044] Mixing: pass pregabalin, mannitol and povidone through a 30-mesh sieve to remove lumps, and mix in a material mixer for 20 minutes after treatment; pass magnesium stearate through a 30-mesh sieve and then mix with pregabalin powder for 3 minutes to obtain the final blend.

[0045] Tablet compression: the blended pregabalin powder is directly compressed with a circular shallow concave punch and a rotary tablet press to control the tablet hardness to 10-20kg.

[0046] Seal coating (optional): A layer of water-soluble seal coating can be coated between the tablet core and the controlled-release film coat, and the coating powder 03A19322-CN is transparent and soluble in pure water. Use a high-efficiency coating pan to coat the tablet core with a sealing layer. The atomization pressure is 0.1-0.2MPa, the tablet bed temperature is 30-40℃, ...

Embodiment 3

[0050] prescription

[0051] I chip

[0052]

[0053] II controlled release film coat

[0054]

[0055] Preparation Process:

[0056] Mixing: pass pregabalin, mannitol and hydroxypropyl cellulose through a 30-mesh sieve to remove lumps, and mix them in a material mixer for 20 minutes after treatment; pass magnesium stearate through a 30-mesh sieve and then mix with pregabalin powder for 3 The final blend was obtained after 1 min.

[0057] Tablet compression: the blended pregabalin powder is directly compressed with a circular shallow concave punch and a rotary tablet press to control the tablet hardness to 10-20kg.

[0058] Seal coating (optional): A layer of water-soluble seal coating can be coated between the tablet core and the controlled-release film coat, and the coating powder 03A19322-CN is transparent and soluble in pure water. Use a high-efficiency coating pan to coat the tablet core with a sealing layer. The atomization pressure is 0.1-0.2MPa, the tablet b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com