Work support apparatus

A technology for supporting devices and operations, applied in storage devices, packaging, assembling machines, etc., can solve problems such as inconvenience and difficulty in giving degrees of freedom, and achieve the effect of cost reduction and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Hereinafter, one embodiment of the work support device suitable for the present invention will be described in detail with reference to the drawings. In addition, the following embodiment shows only an example of this invention, and it goes without saying that the gist of this invention is defined only by a claim.

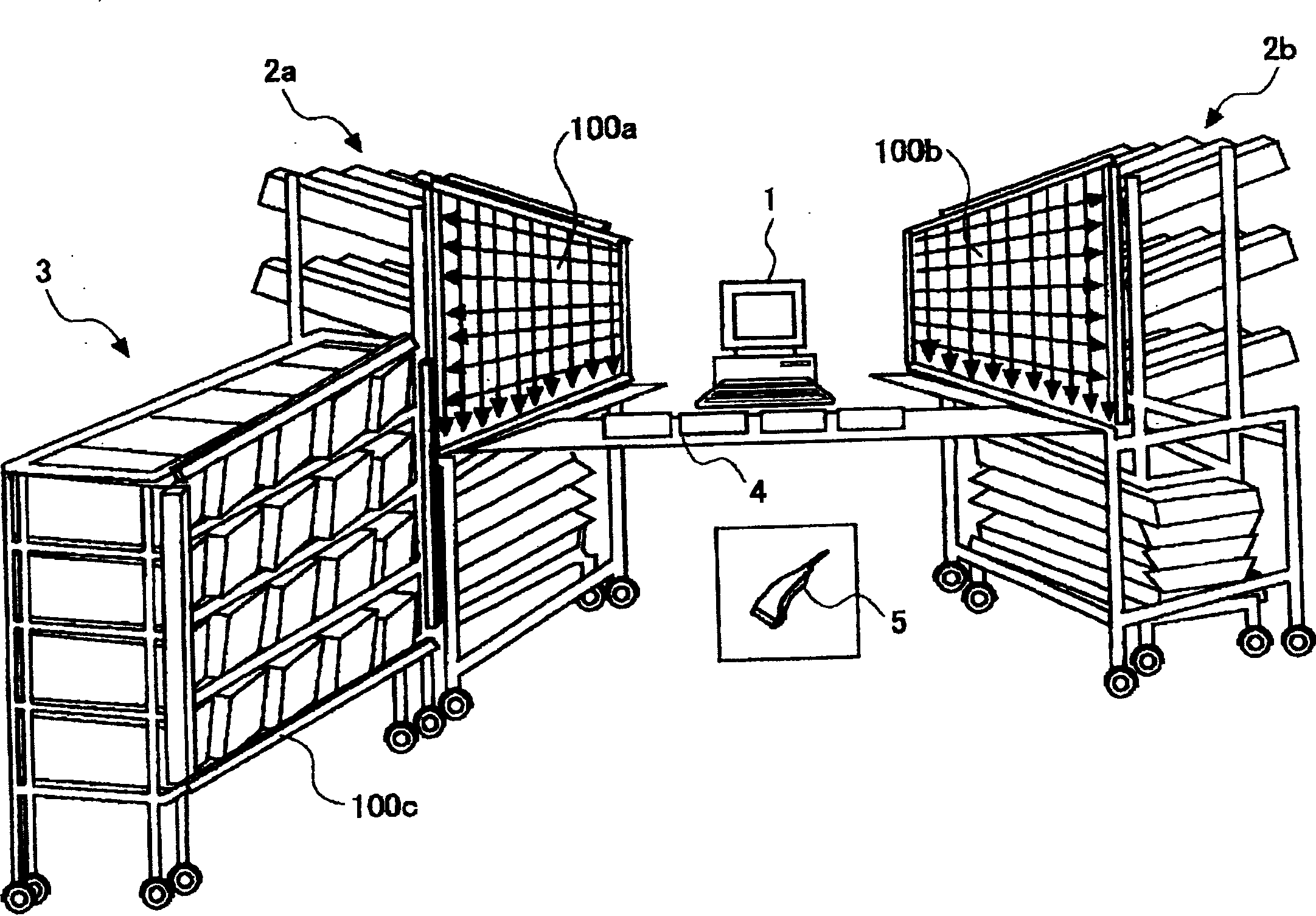

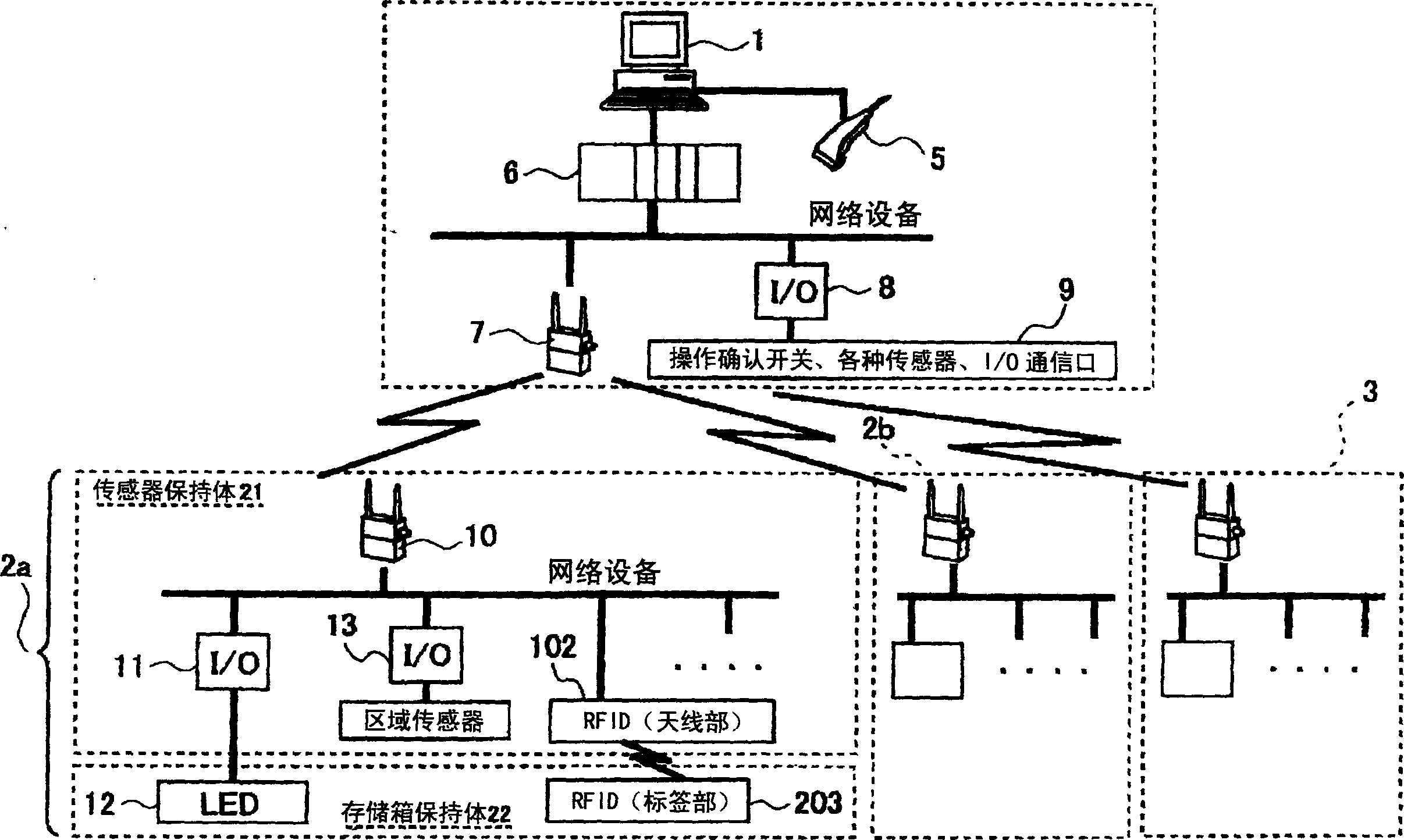

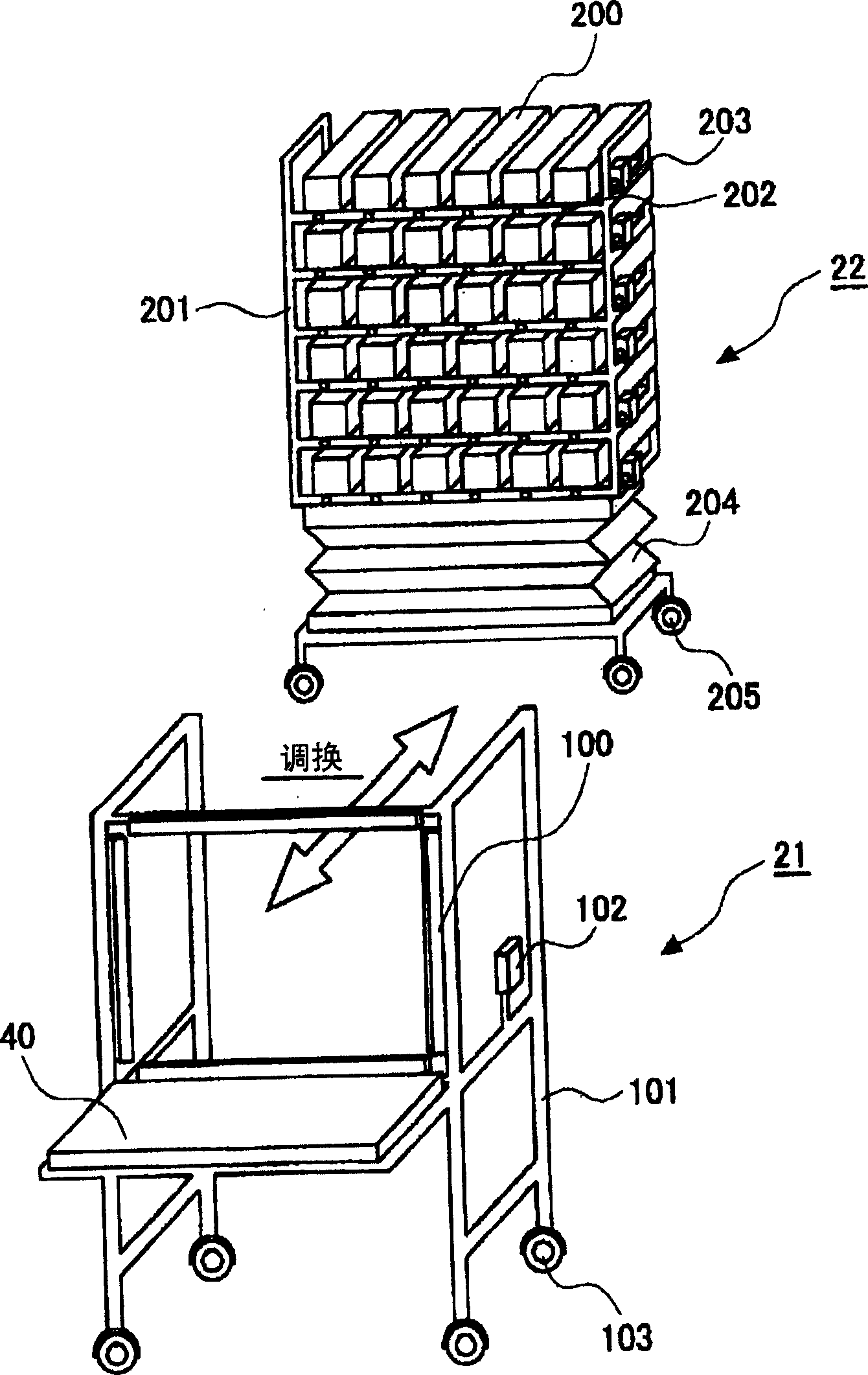

[0058] figure 1 It shows the whole schematic diagram of the work support apparatus related to this invention. As shown in the figure, the work support device of this embodiment has a personal computer 1 as an information processing device, a parts rack 2 for accommodating a plurality of parts storage boxes, a jig rack 3 for accommodating a plurality of jig storage boxes, a console 4, and a bar code Reader 5 is constructed. In this example, the personal computer 1 is arranged in the center of the console 4, and two parts racks 2a and 2b are arranged across the console 4. As shown in FIG. In addition, one jig rack 3 is disposed beside the component rack 2a....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com