Binding clamps and folders

A technology for binding clips and file folders, applied in file folders, printing, etc., can solve problems such as the inability to maintain the state of binding, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

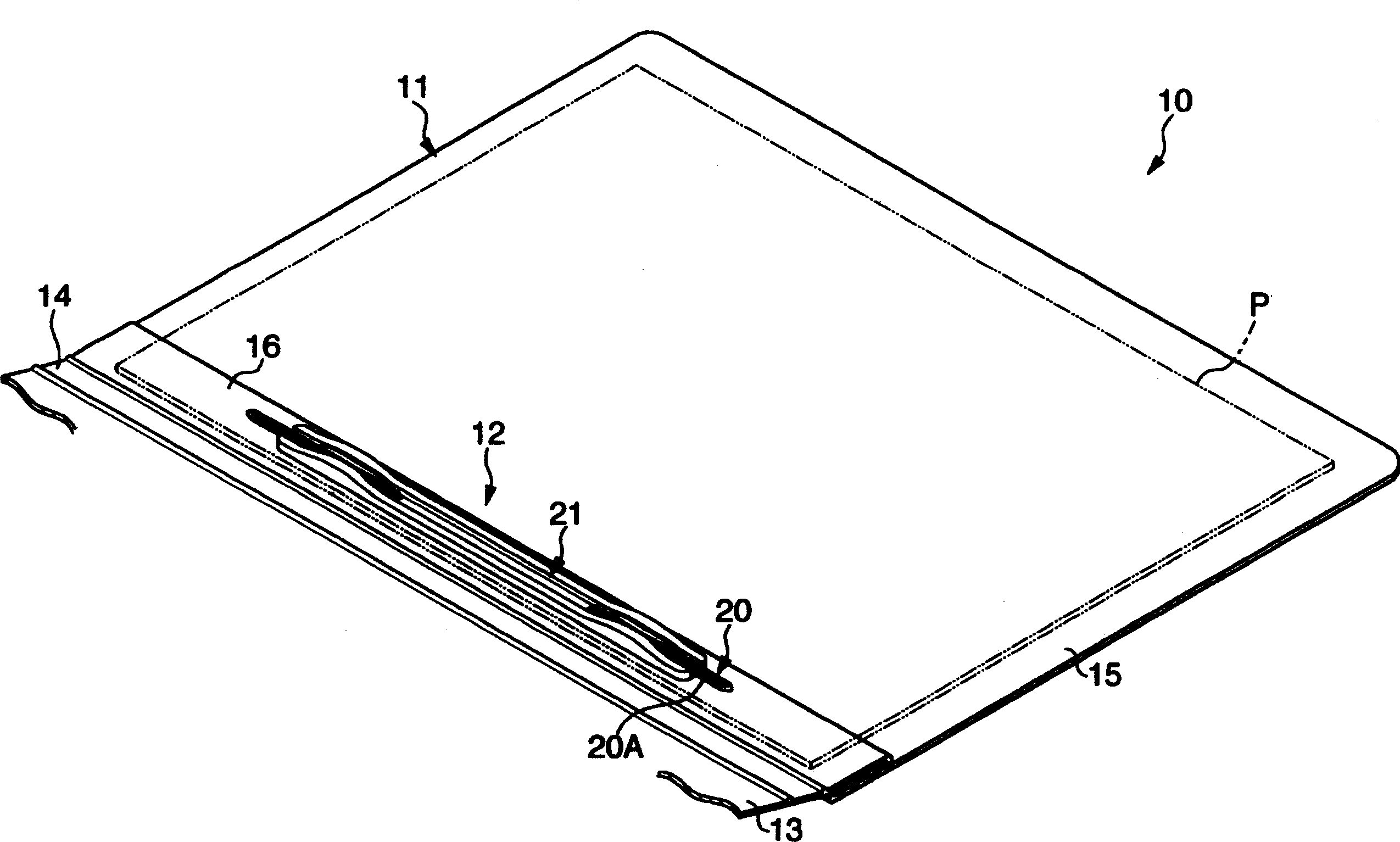

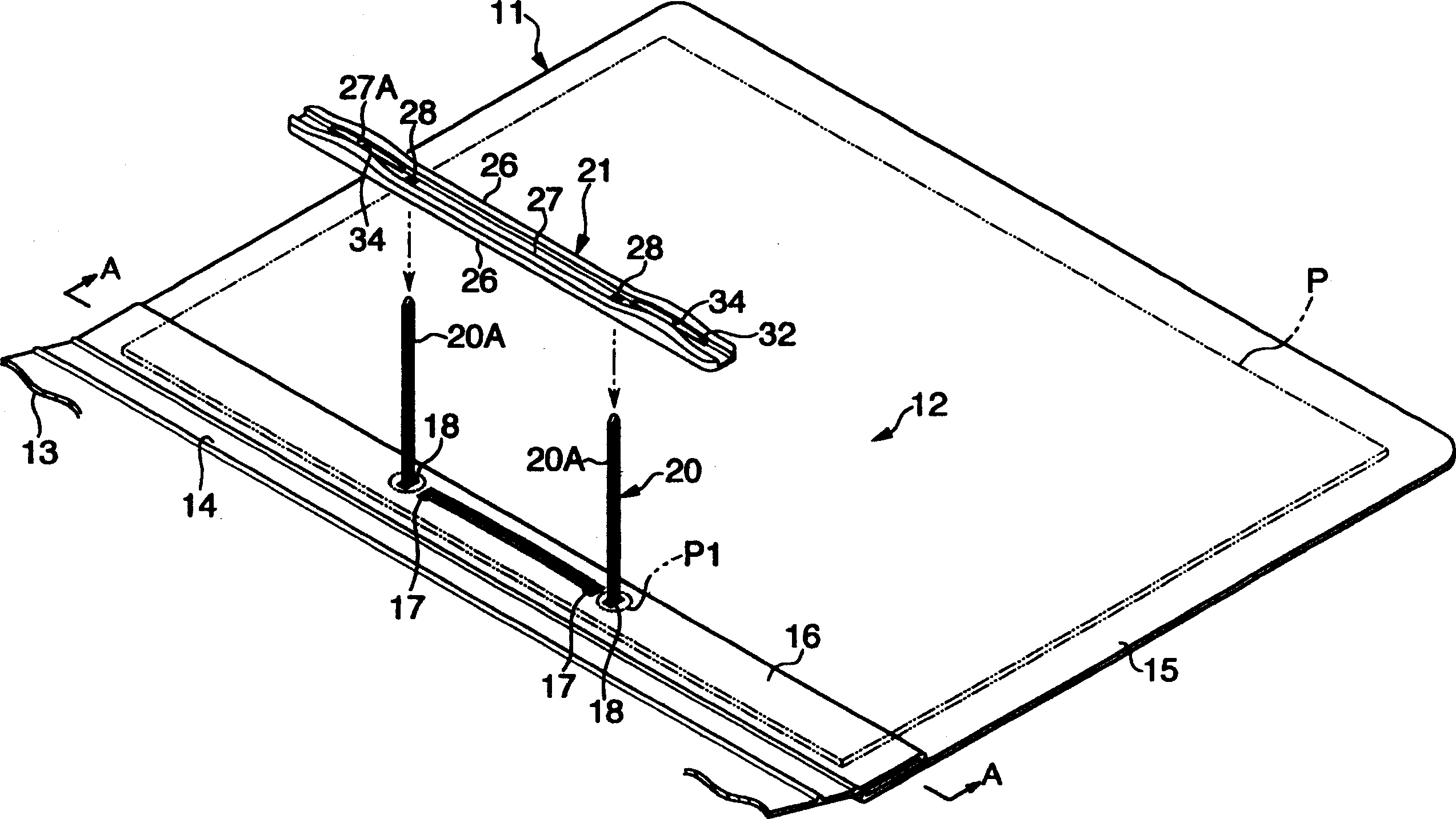

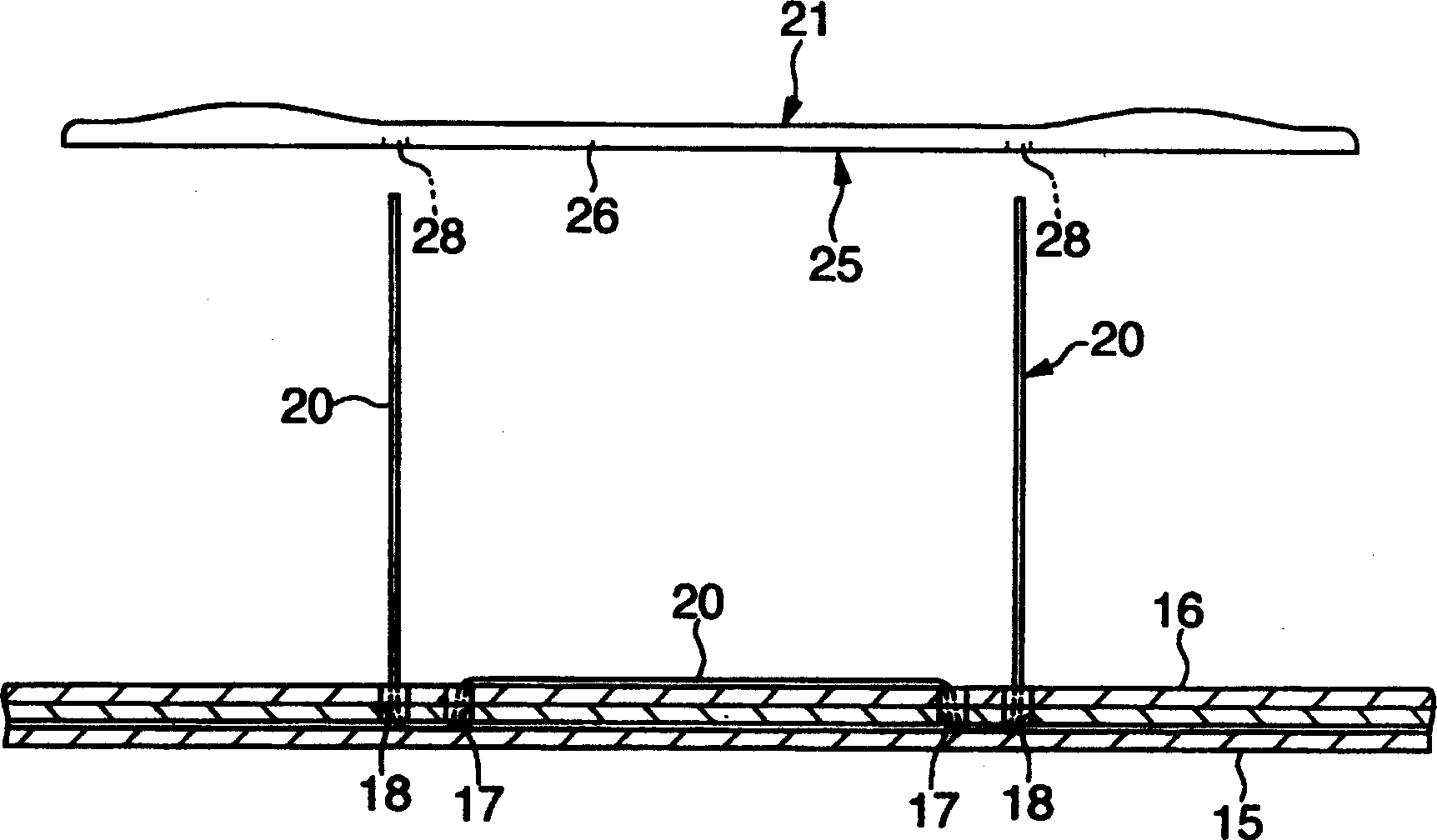

[0060] figure 1 A schematic perspective view showing the opened state of the folder of the first embodiment, figure 2 A schematic perspective view showing the state where the binding plate part is removed from the binding tape. In these figures, the file folder 10 is composed of a leather body 11 and a binder 12 attached to the leather body 11 . The clip leather body 11 consists of a clip surface 13, a clip bottom 15 connected to the clip surface 13 via the clip back 14, and from the inner side of the clip back 14, that is, the junction of the clip back 14 and the clip bottom 15, to the inside. It consists of a sheet-shaped mounting part 16 folded in a double-layered state. like figure 2 As shown, on the two regions of the up and down direction of the mounting part 16, a pair of inner holes 17, 17 and a pair of outer holes 18, 18 are formed. Using these inner holes 17 and outer holes 18, the binding clip 12 It can be freely disassembled relative to the skin body 11 .

...

no. 2 approach

[0072] Second, refer to Figure 8 to Figure 10 A second embodiment of the present invention will be described. In addition, in the following description, the same code|symbol is used for the part which is substantially the same as that of 1st Embodiment, and the description is abbreviate|omitted.

[0073] This second embodiment is characterized in that it is provided with a handle portion 40 for easier pinching when the above-mentioned binding plate member 21 is removed. More specifically, in the base plate 25, a pair of side walls 2626, that is, the side walls 26, 26 located in the central region between the insertion paths 28, 28, are formed on the inside of the base plate 25 in the width direction. Positionally, thus, a structure is formed in which the handle portion 40 is formed on the upper part of the side walls 26 , 26 . In addition, on the lower surface side of the substrate 25, on the inner side immediately adjacent to the insertion paths 28, 28, spacers 42, 42 faci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com