Thread stop motion device and bar

A warp-breaking self-stop and slat technology, applied in transportation and packaging, embroidery machine mechanisms, embroidery machines, etc., can solve the problems of high quality and slow response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

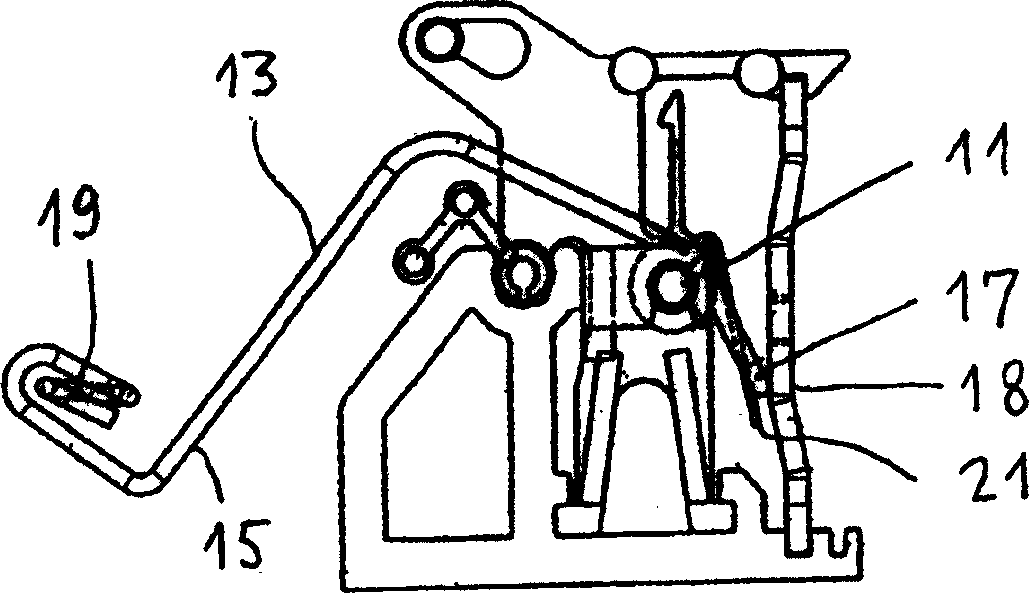

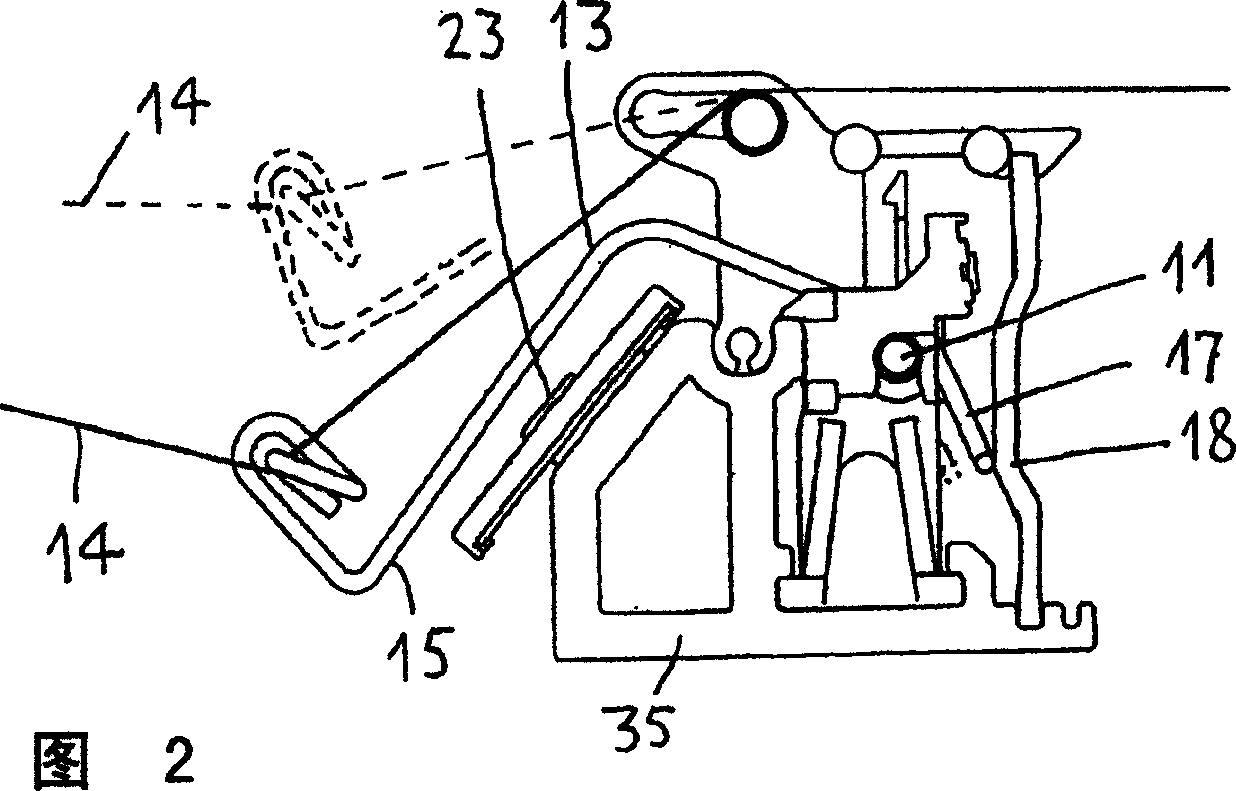

[0021] figure 1 The shown, known prior art warp stop device slat according to EP1098025 has a plurality of warp stop devices for monitoring the thread tension at a plurality of embroidery points such as a shuttle embroidery machine. Each broken warp self-stop device has a switch warp stop piece 13 that can turn around the axle 11, and it is made of wire and has two lever arms 15,17. An eyelet 19 for receiving a face yarn is provided on the lever arm 15 . A spring 21 acts on the lever arm 17, and it will make the switch stop piece 13 enter the position shown in the figure together with the gravity acting on it, where the lever arm 17 contacts the contact rail 18. Thus a fault signal is generated to indicate a broken yarn. Usually, when the embroidery machine is working, the tension in the face yarn 14 lifts the switch warp stop piece, as shown by the dotted line in FIG. 2 , thus preventing contact with the contact rail 18.

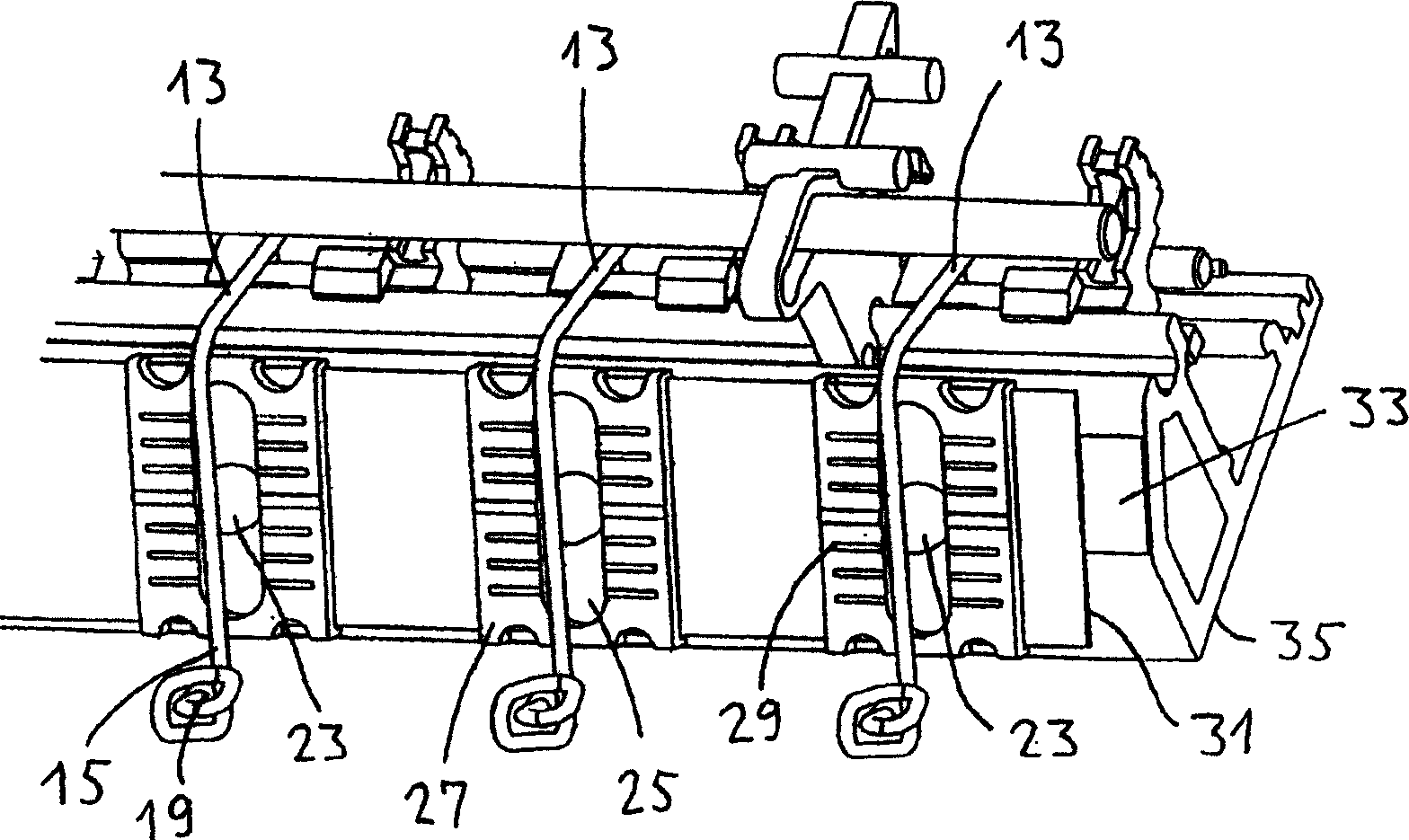

[0022] Figures 2 and 3 show the position of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com