Three freedom serial-parallel mixed robot driven by ball spline

A ball spline and spline drive shaft technology, used in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of motion clearance, large inertia, and long mechanical setup time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

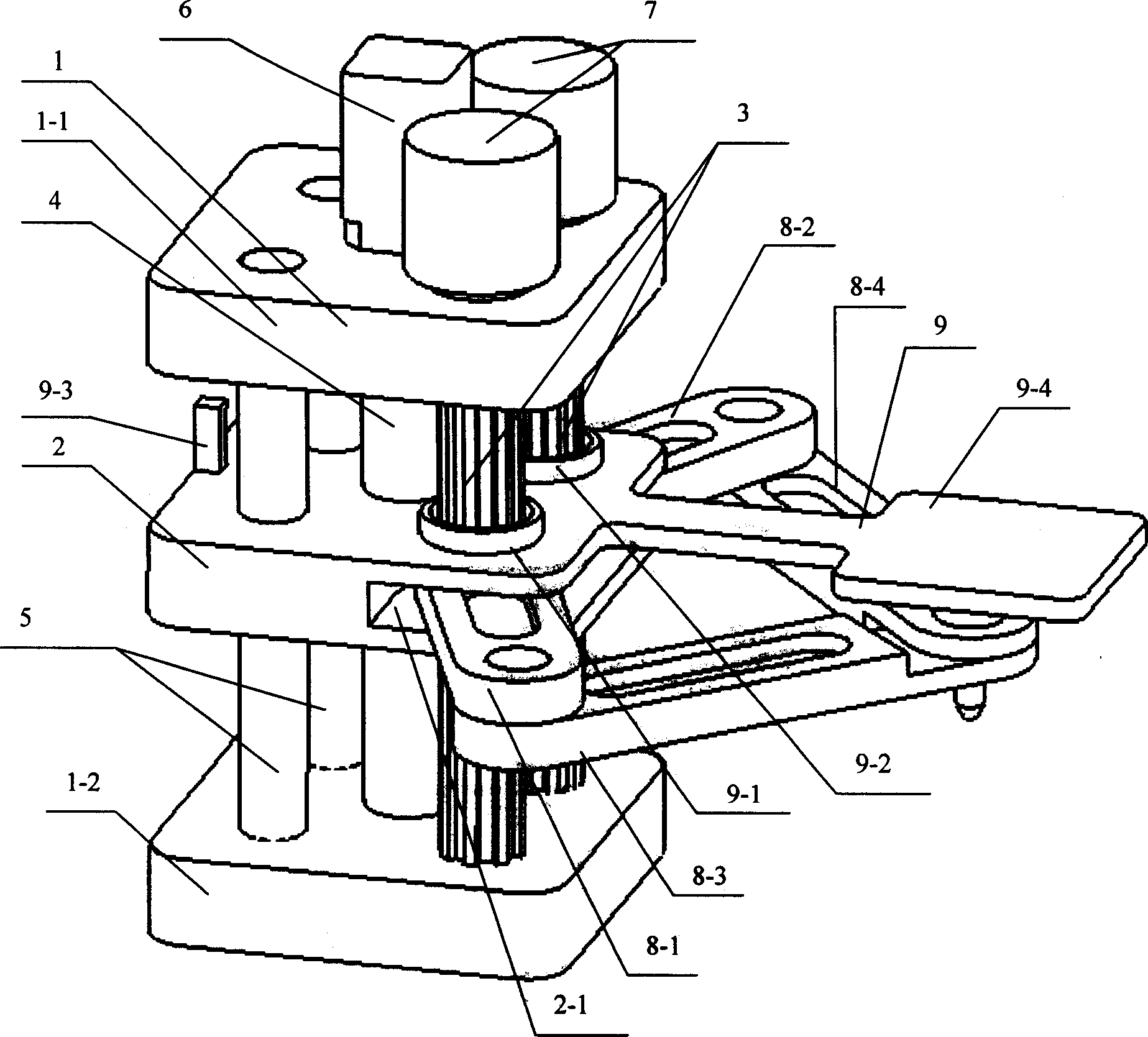

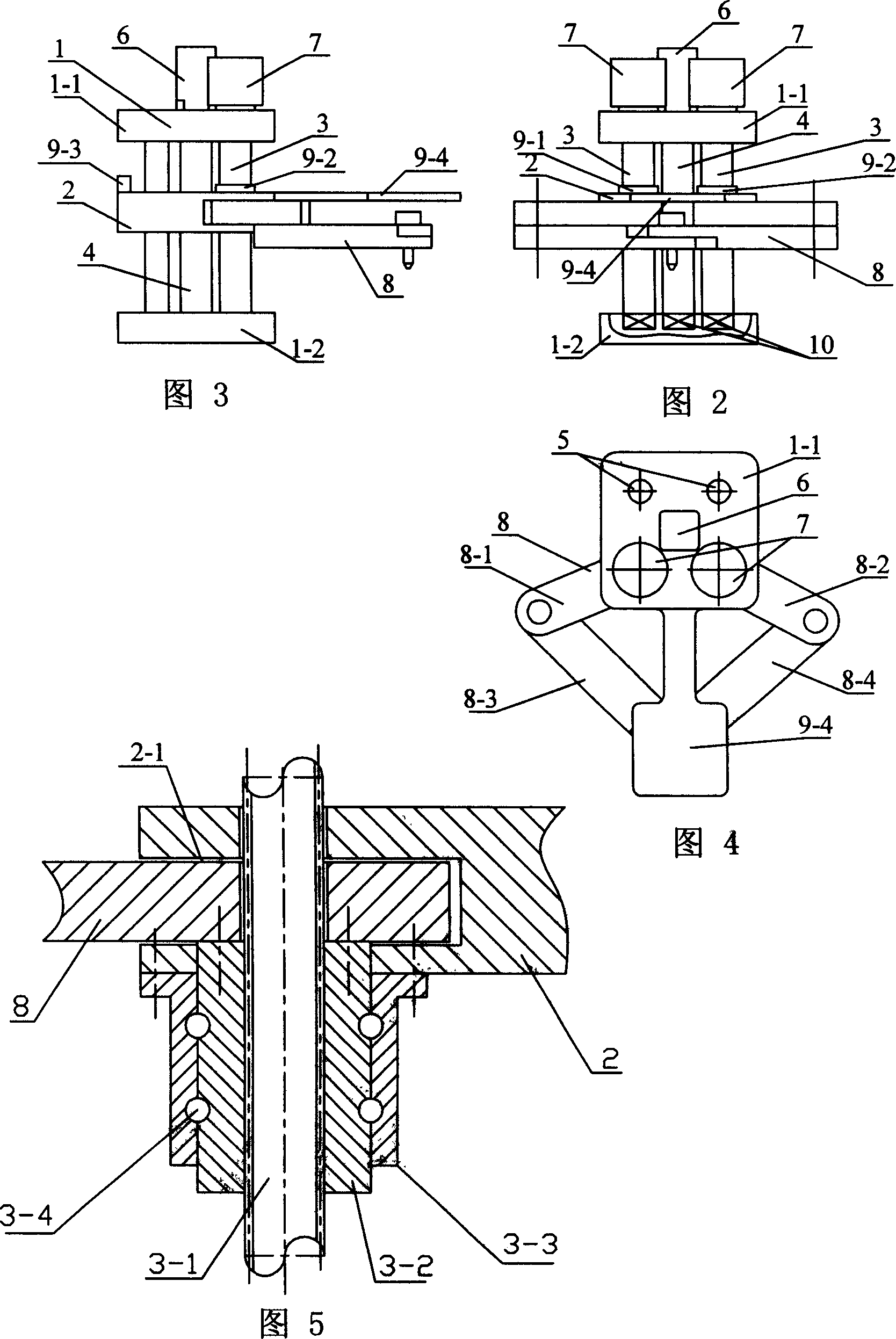

[0005] Specific Embodiment 1: This embodiment includes a base 1, the base 1 includes an upper base 1-1 and a bottom base 1-2, and a movable Platform 2, between upper base 1-1 and bottom base 1-2, be provided with spline driving shaft 3, leading screw 4 and guide rail 5 that longitudinally pass through mobile platform 2, and the two ends of described guide rail 5 are respectively connected with The upper base 1-1 and the bottom base 1-2 are fixedly connected, the upper end of the screw 4 is connected with the servo motor 6, the upper end of the spline drive shaft 3 is connected with the direct drive motor 7, and the spline drive The outer ring 3-3 of the shaft 3 is connected with the mobile platform 2, and the inner ring 3-2 is connected with the rod 8. A right circular grating 9-1 and a left circular grating 9-2 are installed between the rod 8 and the splined outer ring. Linear grating 9-3 and planar grating 9-4 are also housed on mobile platform 2.

specific Embodiment approach 2

[0006] Specific implementation mode two: refer to figure 1 , Fig. 2, Fig. 3, Fig. 4, present embodiment guide rail 5 is two, and two guide rails 5 are all arranged vertically with mobile platform 2, and the two ends of every guide rail 5 are connected with upper base 1-1 and bottom base respectively 1-2 fixed connection; the servo motor 6 in this embodiment is an AC servo motor, the direct drive motor 7 is a voice coil servo motor, the upper end of the spline drive shaft 3 is connected to the voice coil servo motor 7, and the The spline drive shaft 3 includes a spline shaft 3-1, an inner ring 3-2, an outer ring 3-3 and a ball 3-4, and a ball 3-4 is arranged between the inner ring 3-2 and the outer ring 3-3. 4. The mobile platform 2 is fixedly connected to the outer ring 3-3 of the spline drive shaft 3. The aforementioned spline drive shafts 3 are two, and the two spline drive shafts 3 are connected to the mobile platform 2. There is a transverse through groove 2-1, and the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com