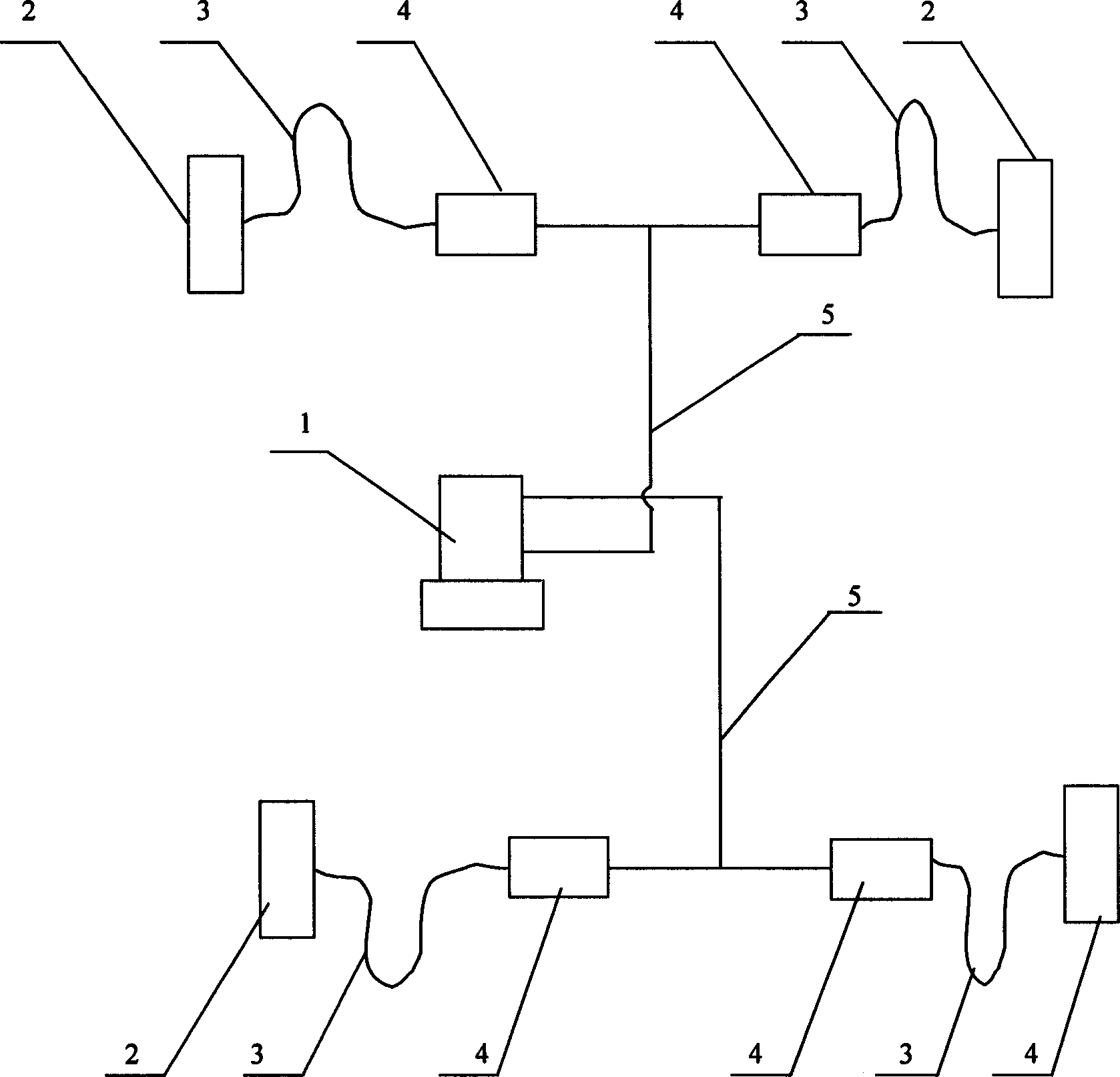

Vehicle braking system and hydraulic (steam pressure) conducting protector for preventing brake not work

A technology of automobile brakes and protectors, which is applied in the direction of brake safety systems and pipeline layouts, to achieve the effects of avoiding major traffic accidents, convenient installation, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

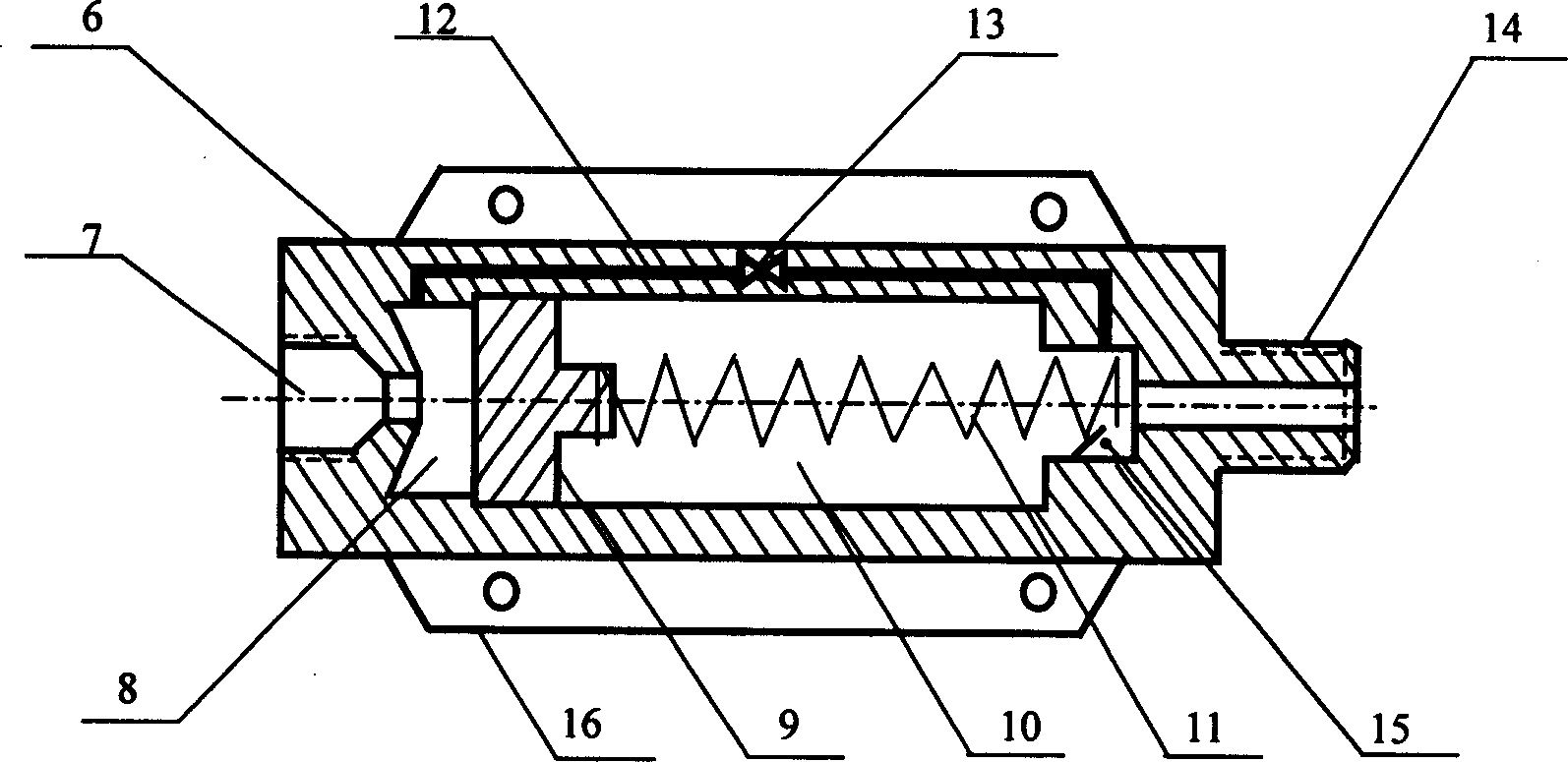

Embodiment 1

[0020] Example 1: figure 2 A schematic diagram of the structure of the hydraulic conduction protector is provided. It can be seen from the figure that the hydraulic conduction protector is composed of a housing 6, a plunger 9, a spring 11, an emptying auxiliary line 12, and an auxiliary line valve 13. The middle of the housing 6 is empty. The chamber is the main oil circuit. One end of the housing 6 has an oil inlet 7, which is connected to the master pump oil pipeline 5; the other end has an interface 14, which communicates with the oil storage chamber 10 at the rear end of the plunger 9. The interface 14 communicates with the brake hose 3 . The plunger 9 separates the main oil circuit into two oil storage chambers in the middle cavity. Between the front end of the plunger 9 and the oil inlet 7 is an oil storage chamber 8, between the rear end of the plunger 9 and the interface 14 is an oil storage chamber 10, the spring 11 is installed at the rear end of the plunger 9, and...

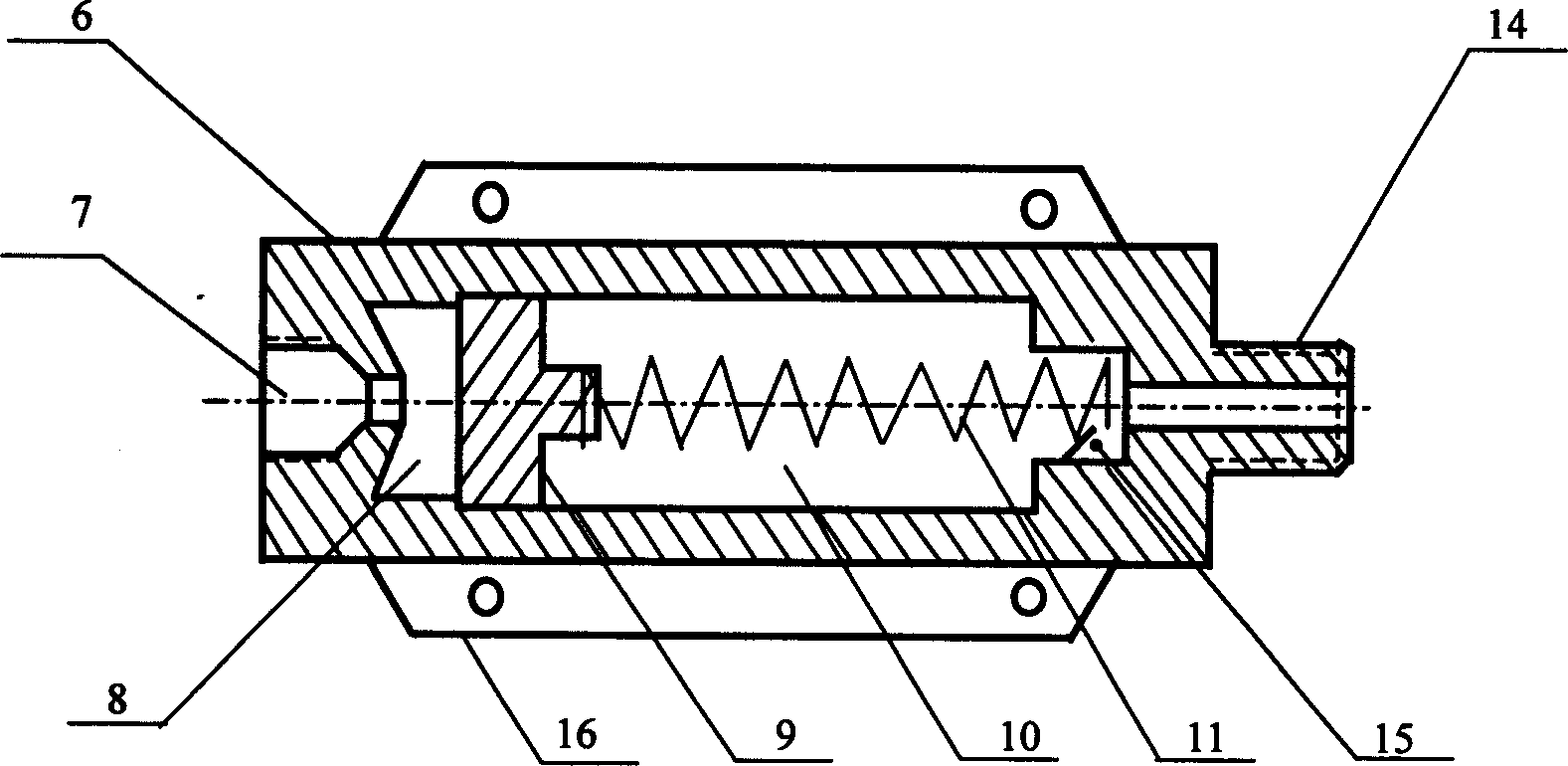

Embodiment 2

[0021] Example 2: image 3 Provided is a schematic diagram of the structure of the air pressure conduction protector used in the air pressure brake system. The air pressure conduction protector is composed of a housing 6, a plunger 9 and a spring 11. The middle of the housing 6 is a cavity as the main air circuit, and one end has an inlet The air port 7 has an interface 14 at the other end; the plunger 9 divides the main air path into two air storage chambers 8 and 10 in the cavity, and the air storage chamber 8 is between the front end of the plunger 9 and the air inlet 7, Between the rear end of the plunger 9 and the interface 14 is an air storage chamber 10, and the spring 11 is placed in the air storage chamber 10 at the rear end of the plunger 9; the air storage chamber 8 at the front end of the plunger 9 communicates with the master cylinder oil through the air inlet 7 The pipeline 5 and the air storage chamber 10 at the rear end of the plunger 9 are connected to the bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com