Monochromator of chip tester

A technology of wafer testing and monochromator, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of heavy testing table, affecting the testing rate, reducing the accuracy of test results, etc., achieving simple adjustment, shortening adjustment time, Easy to adjust effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

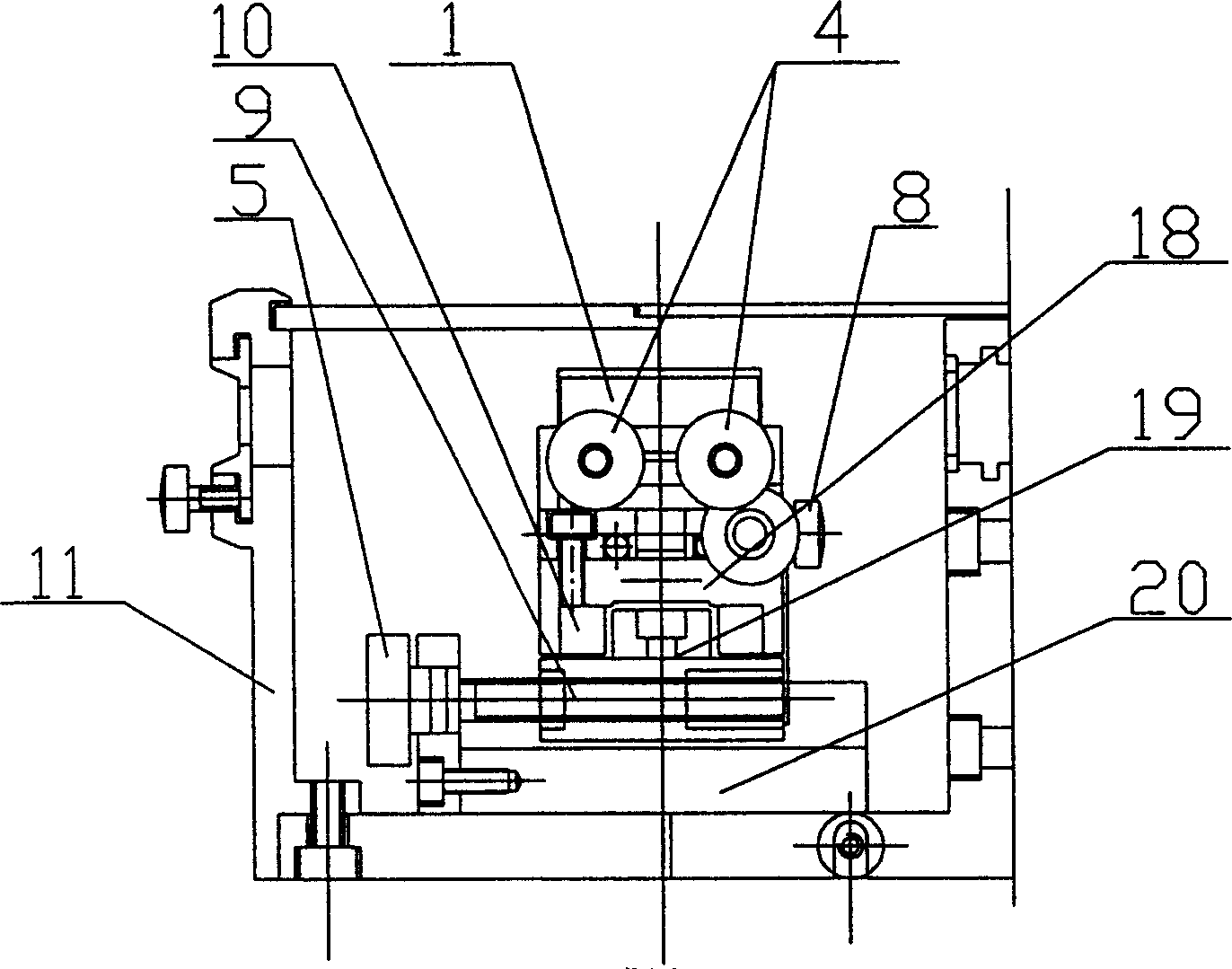

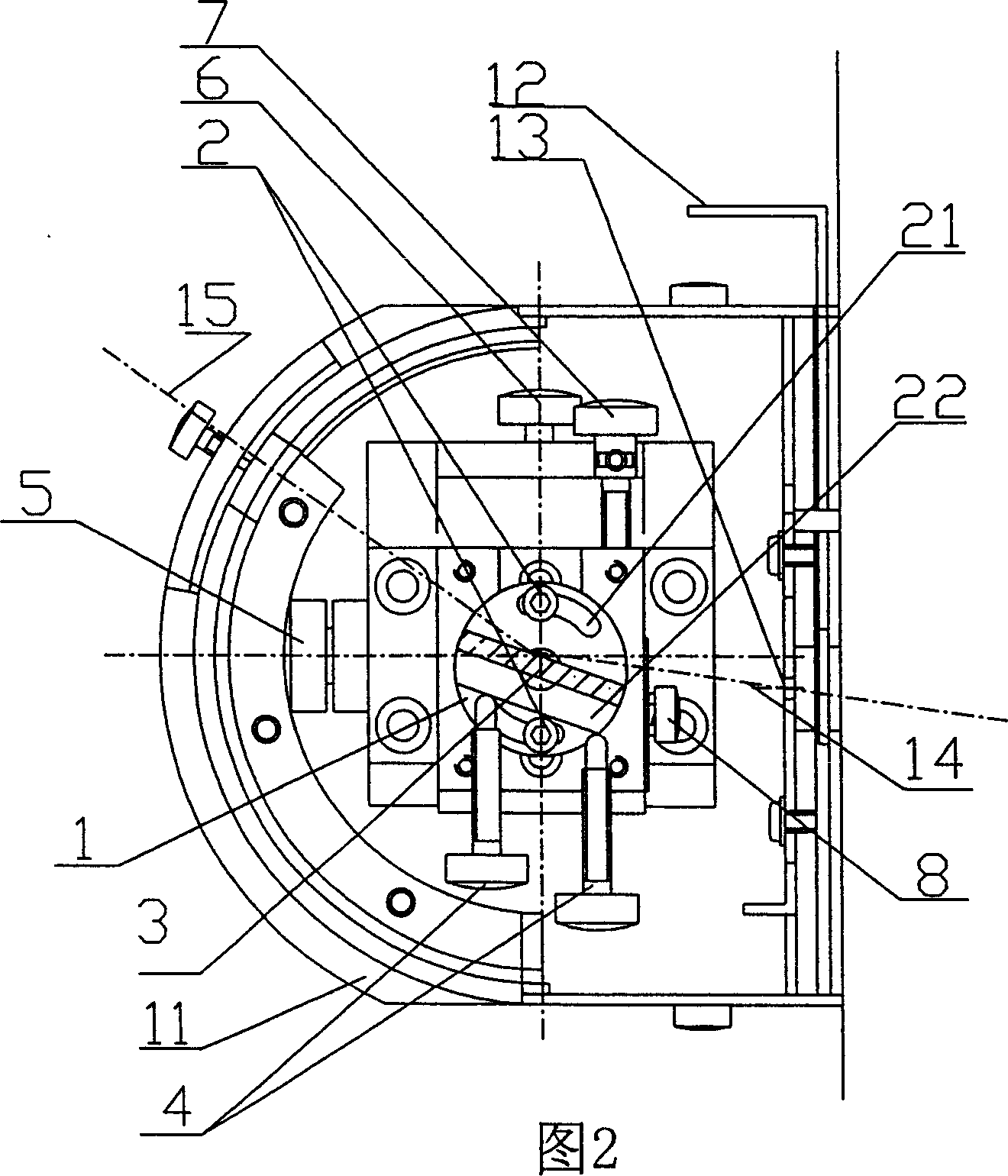

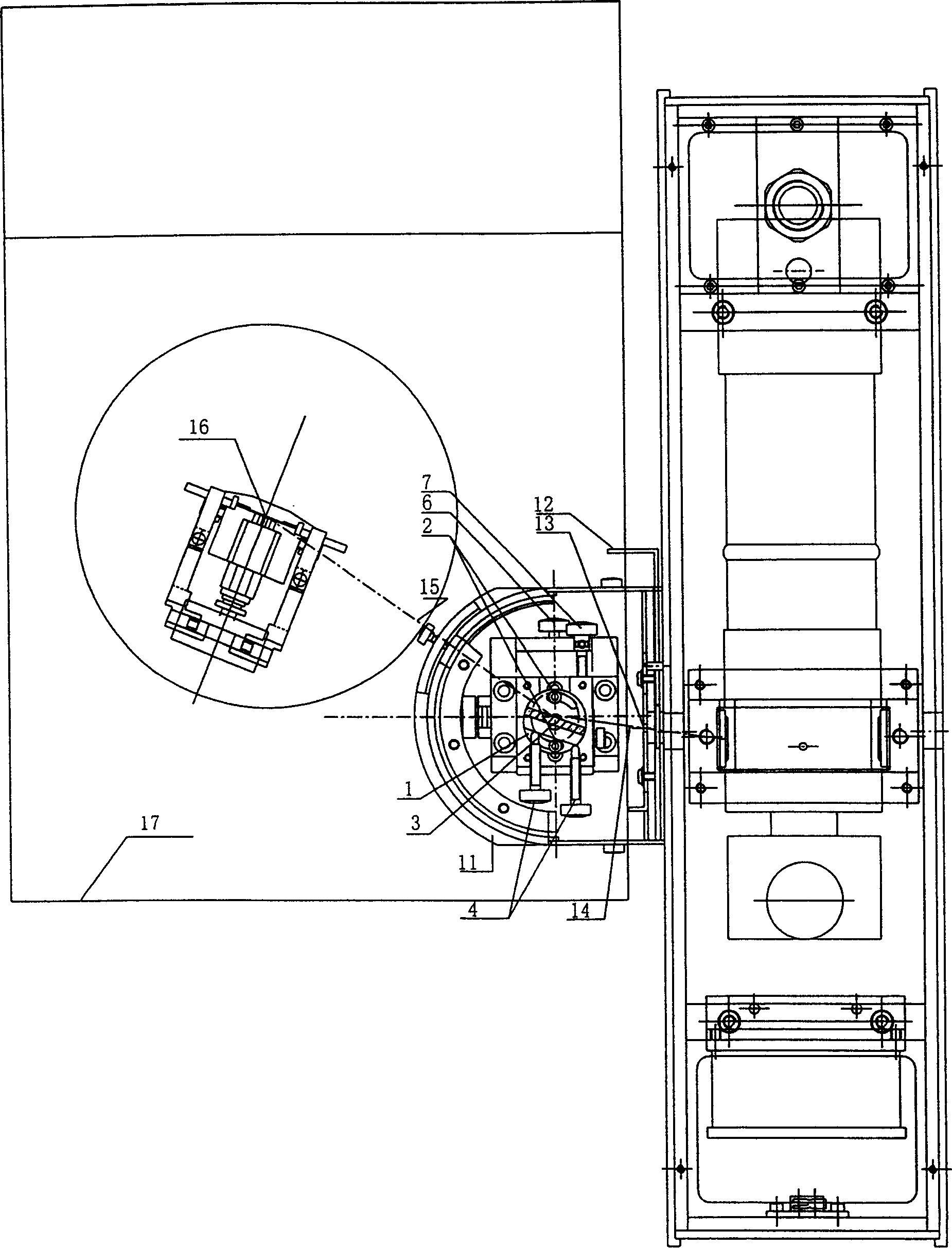

[0010] The outer cover 11 is covered on the base 20, and the base 20 has a slider 19 in the X direction. The X-direction guide rail 9 is distributed on both sides of the bottom of the X-direction slide block 19, and one end of the head of the X-direction adjustment screw 5 is rotationally connected with the base 20, and the other end is threadedly connected with the X-direction slide block. The X direction guide rail adjustment screw 5 is parallel to the X direction guide rail 9; there is an X direction guide rail fixing screw 6 in the orthogonal direction to the X direction guide rail adjustment screw 5 . There is a Y direction slide block 18 above the X direction slide block. The Y-direction guide rail 10 is distributed on both sides of the bottom of the Y-direction slide block 18; one end of the head of the Y-direction guide rail adjustment screw 7 is rotationally connected with the X-direction slide block 19, and the other end is threadedly connected with the Y-direction s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com