Bulk producing controlling method based on bulk producing controlling system

A mass production and control system technology, applied in general control systems, control/regulation systems, program control in sequence/logic controllers, etc. The effect of normal production needs, elimination of execution failures, and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

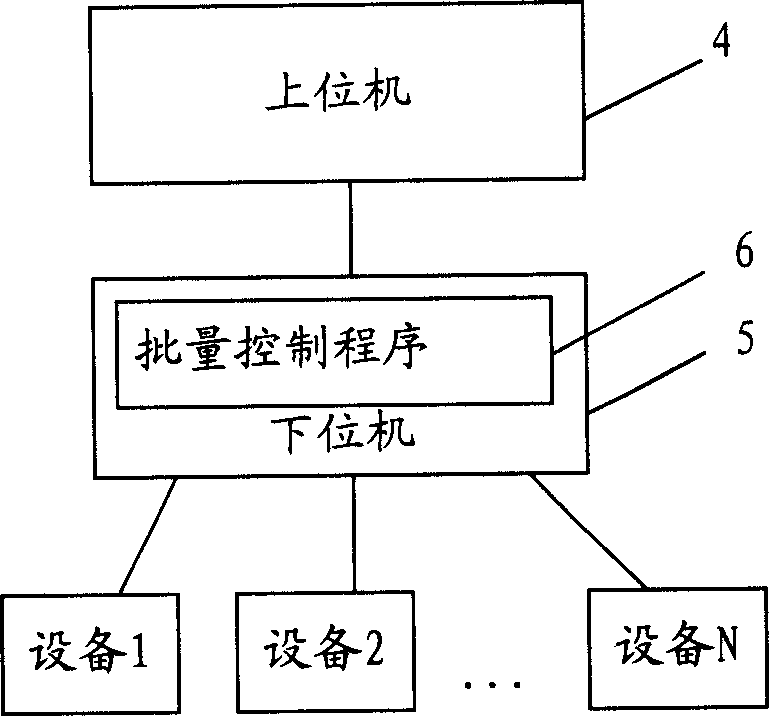

[0032] see also figure 1 , the batch production control system includes a host computer 4 and a lower computer 5 connected to the field equipment, a batch control program 6 is set on the lower computer 5, the code of the batch control program 6 is executed, a corresponding control command is generated and the control command is sent to the corresponding device to modify the actual state of the device.

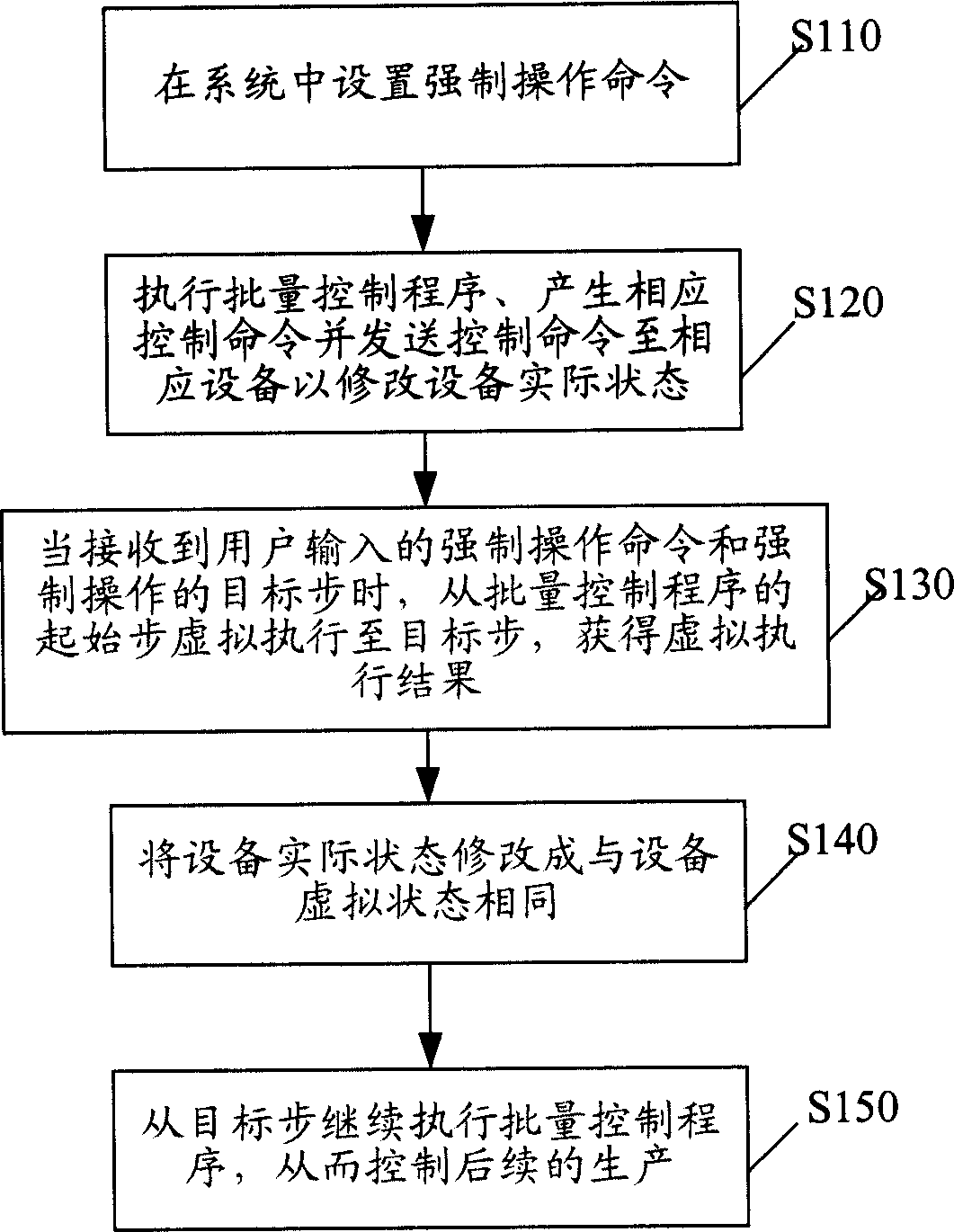

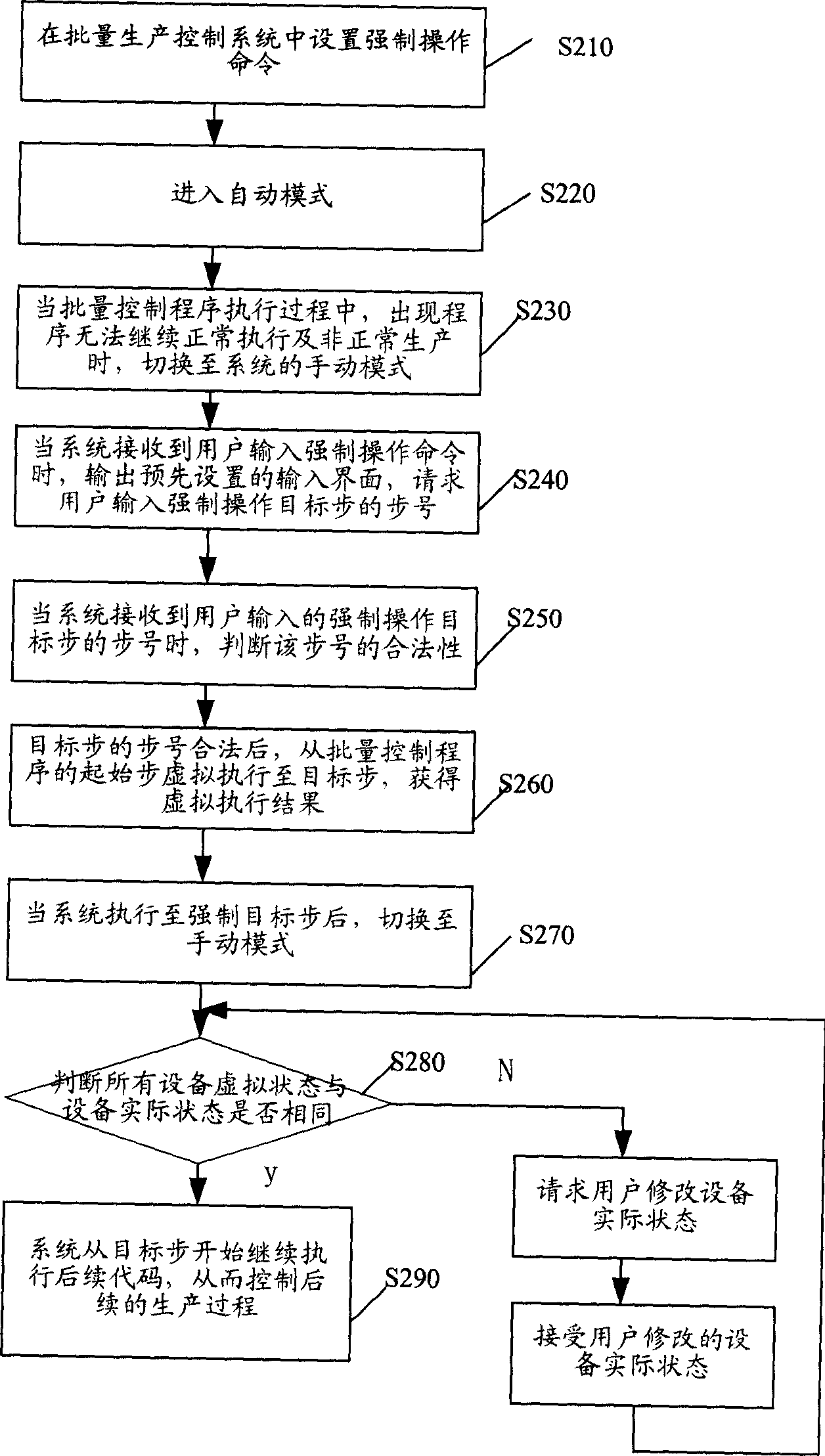

[0033] see figure 2 , which is a principle flow chart of a batch production control method based on the above batch production control system of the present invention. it includes

[0034] S110: setting a mandatory operation command in the system;

[0035] S120: Execute the batch control program 6, generate a corresponding control command and send the control command to the corresponding device to modify the actual state of the device;

[0036] S130: When receiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com