Heat melting butt joint welder for plastic pipe

A hot-melt butt joint and plastic pipe technology, which is applied in the field of plastic pipe hot-melt butt welders, can solve the problems of inaccurate temperature control of the heating plate, poor welding quality and stability, and low degree of automation, and achieve stable and reliable welding quality. Welding cycle, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

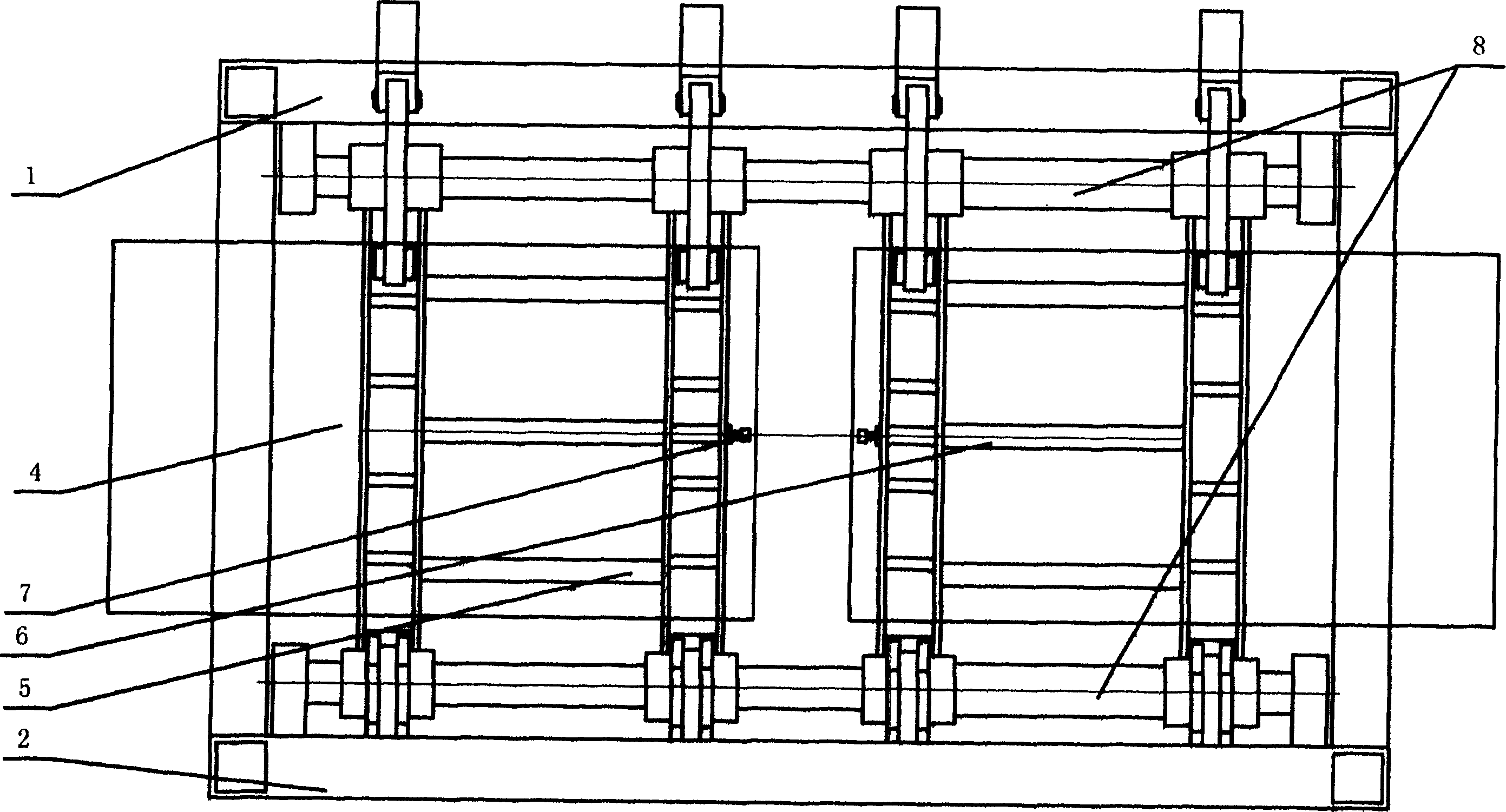

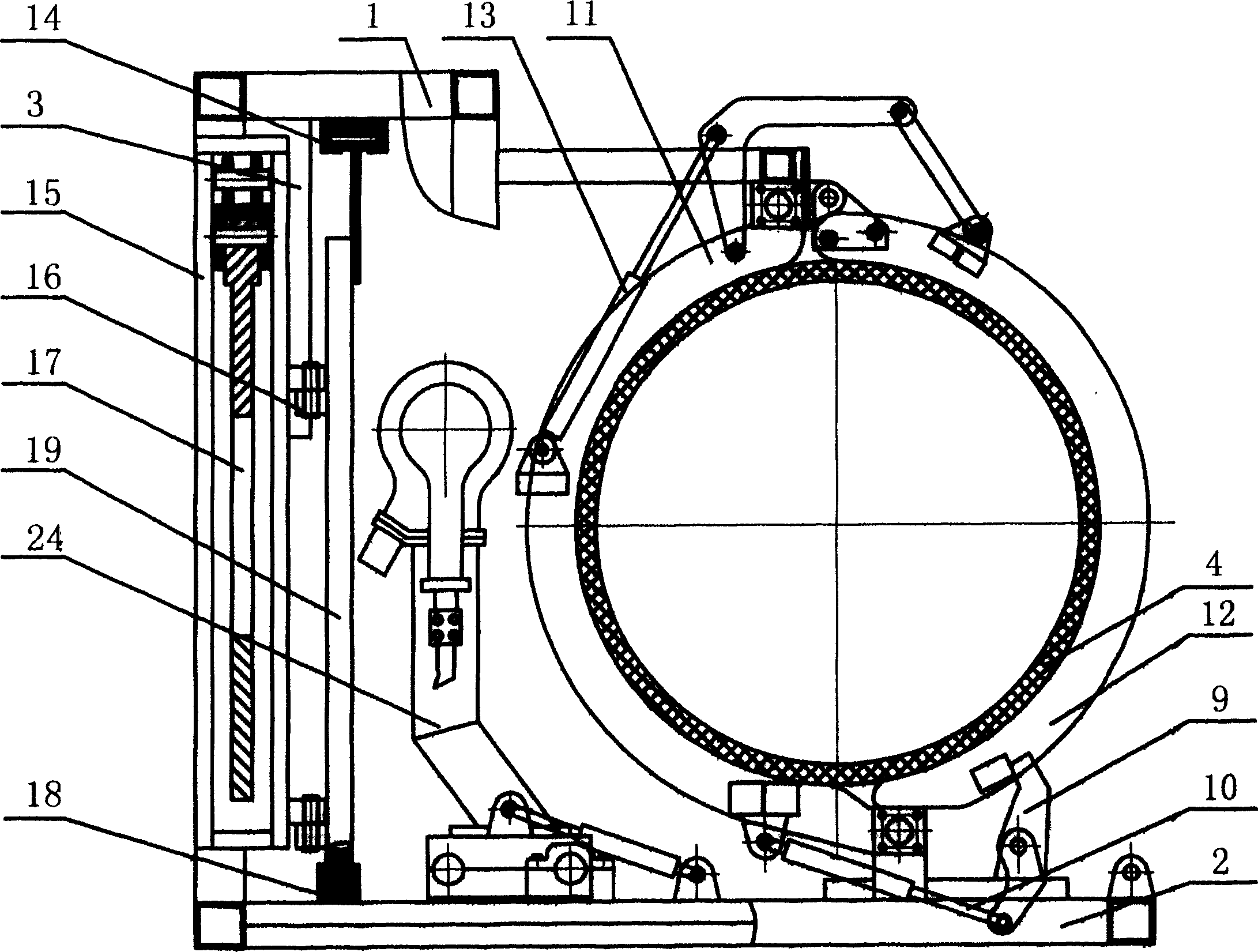

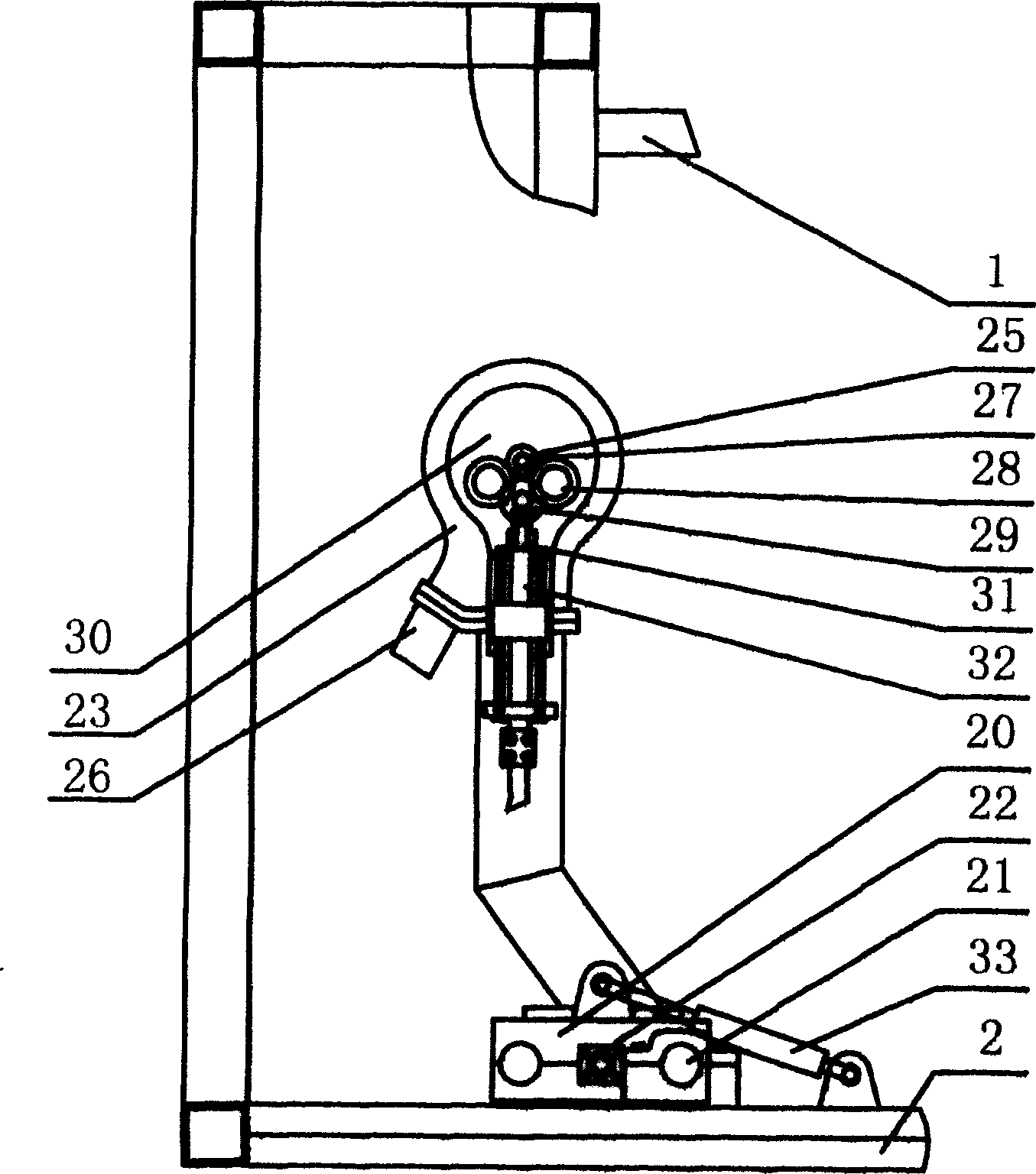

[0021] The present invention mainly comprises the frame that is made of upper frame 1 and lower frame 2 with controller 3, the clamping device placed on the frame, cutting device 24, heating device.

[0022] The clamping device includes a fixed clamping group 5 and a moving clamping group 6 . The fixed clamping group 5 consists of a fixed clamp 11 placed between the upper frame 1 and the lower frame 2, a movable clamp 12 connected with the fixed clamp 11 with a movable oil cylinder 13, and a movable clamp 12 with a clamping oil cylinder 10 placed at the bottom of the fixed clamp 11. Clamping hooks 9 etc. constitute; the mobile clamping group 6 consists of mobile cylinders 8 respectively placed on the upper frame 1 and the lower frame 2, fixed clamps 11 placed between the mobile cylinders 8, connected with the fixed clamps 11 and movable The movable clip 12 of the oil cylinder 13 is placed in the clamping hook 9 etc. of the fixed clip 11 bottom band clamping the oil cylinder 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com