Automatic monitoring method for cement-soil stirring pile construction

A technology for cement-soil mixing piles and automatic monitoring, which is applied to sheet pile walls, infrastructure engineering, signal transmission systems, etc., can solve problems such as difficulty in management, engineering can not meet the design, and the depth of the pile is not in place, and it is convenient to carry. , Simple to use, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

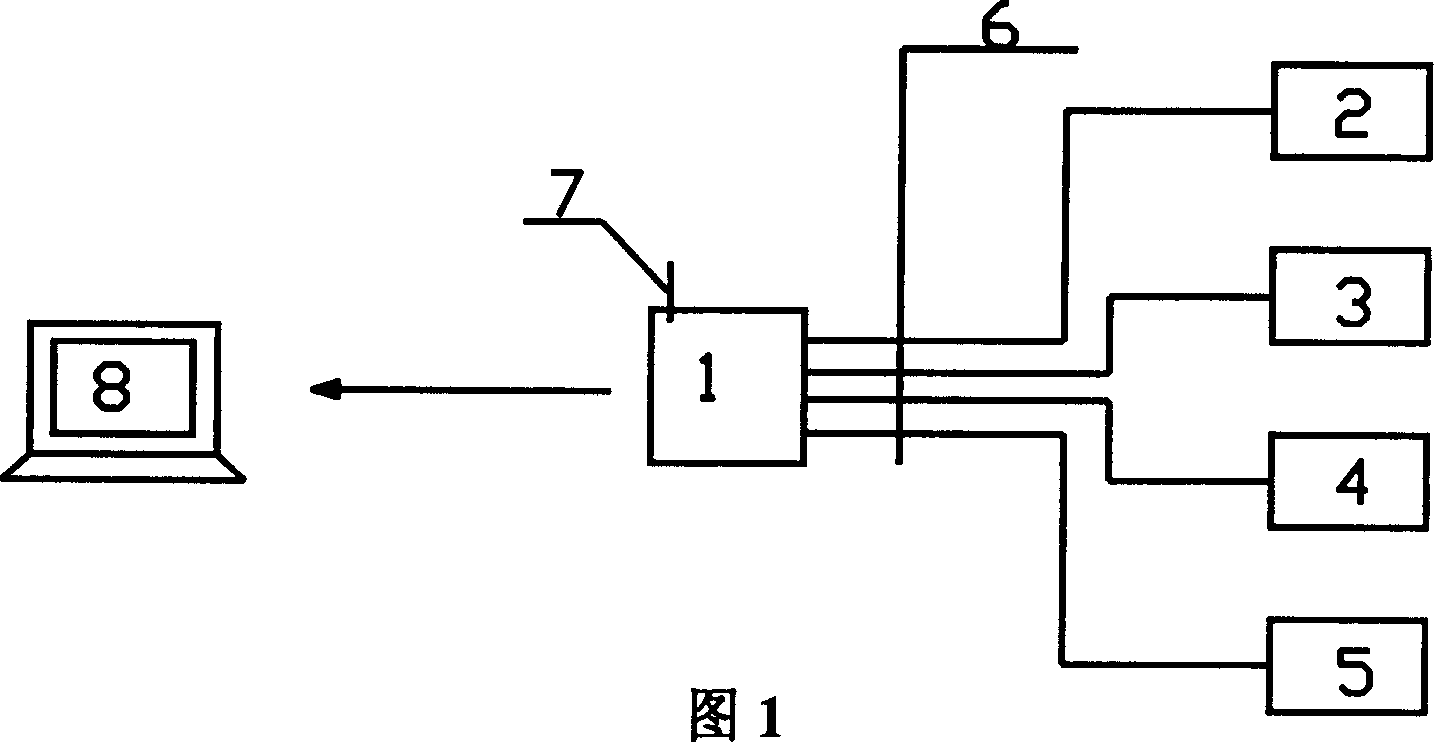

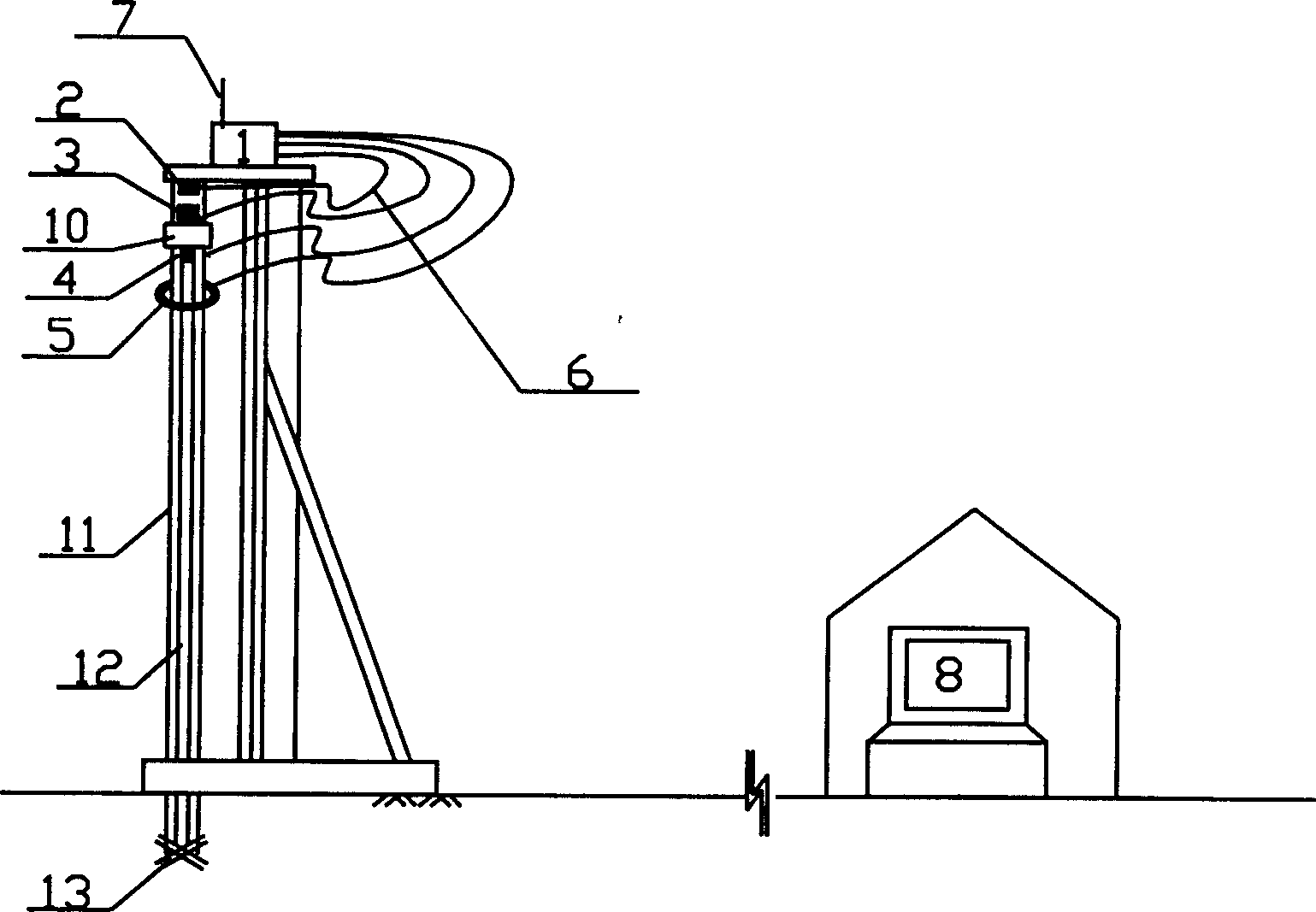

[0014] As shown in Figures 1 and 2, first, the footage sensor 2, the flow sensor 3, the density sensor 4, and the rotation sensor 5 are fixed on the cement-soil mixing pile frame 9. Wherein the footage sensor 2 is arranged on the top of the vibrating head 10 to record the depth of the pile in real time; the flow sensor 3 and the density sensor 4 are arranged in the slurry (powder) pipe 12 to record the amount of slurry and the slurry (powder) in real time density; and the rotation sensor 5 is arranged on the stirring shaft 11 below the vibrating head 10 to record the rotation of the stirring shaft 11 in real time and reflect the characteristics of the underground soil; On the collector 1; the data collector 1 is connected with the antenna 7, and the antenna 7 is best arranged on the top of the frame 9 of the cement-soil mixing pile.

[0015] After starting to implement, under the action of the vibrating head 10, the stirring shaft 11 starts to stir, and the cement slurry or po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com