Method for identifying fly ash leading to concrete and mortar defects

A technology for fly ash and concrete, which is applied in the direction of material analysis using radiation diffraction to achieve the effect of improving accuracy and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take the fly ash raw material from the ready-mixed concrete mixing plant.

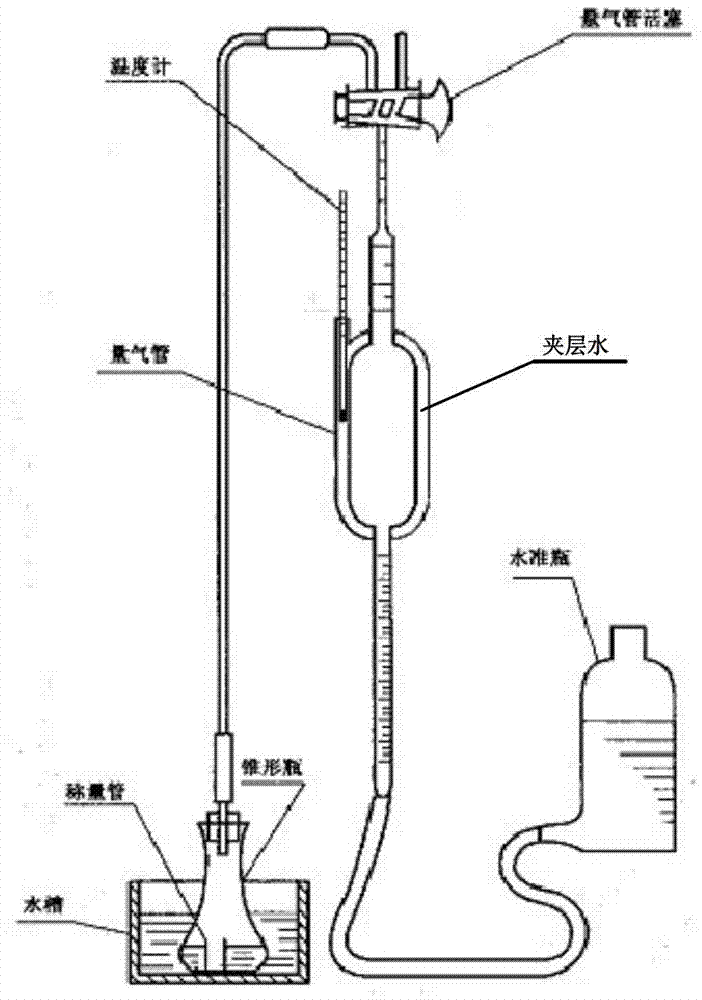

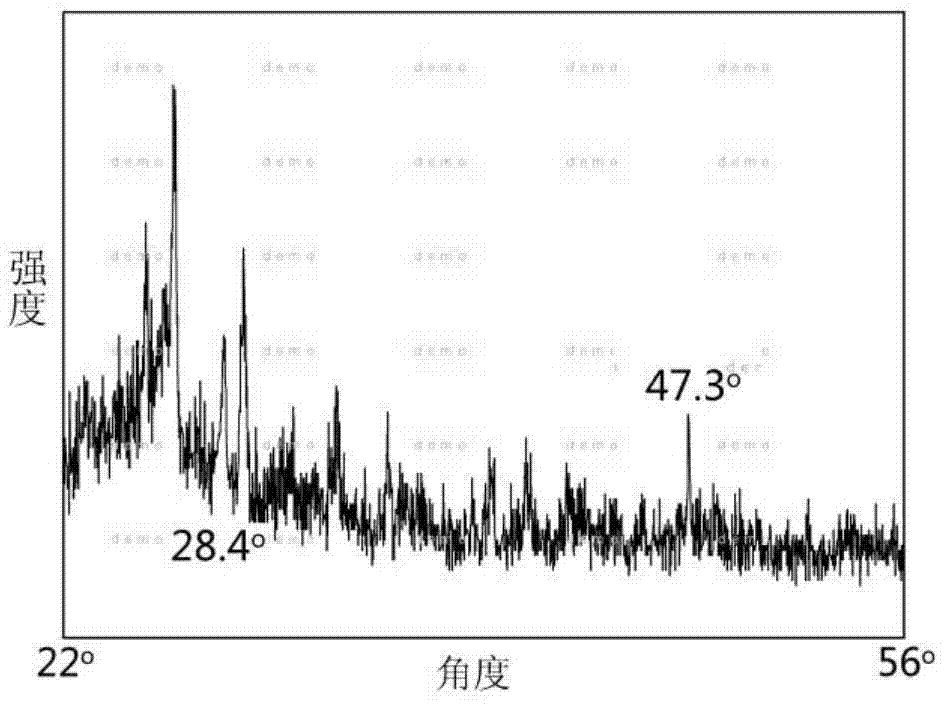

[0023] Carry out phase analysis to fly ash sample on X-ray diffractometer, obtain the X-ray diffraction spectrum figure of this sample ( figure 2 ).

[0024] Two diffraction peaks of 28.4° and 47.3° appeared in the sample X-ray diffraction spectrum at the same time, it can be considered that the sample has the potential danger of causing concrete and mortar defects. Continue to use the gas measuring instrument to measure the gas volume (V) and gas generation duration (t) per unit mass of the sample in the NaOH alkaline solution with a pH of 13. The amount of NaOH alkaline solution is 500mL, and the fly ash is added The amount is 10g. During the whole process, the indoor ambient temperature, cooling water and interlayer water temperature were kept at 20°C. The obtained V and t are 1.20mL / g and 5h respectively, both of which exceed the critical value of 0.20mL / g and 2h. It is considered that t...

Embodiment 2

[0026] Take the fly ash raw material from the ready-mixed concrete mixing plant.

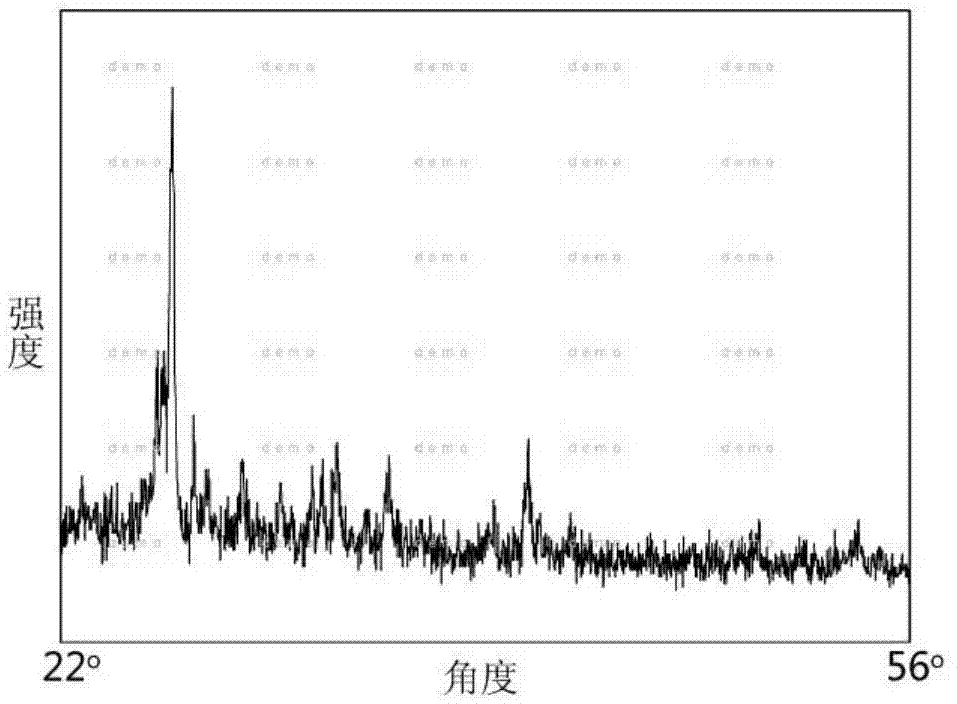

[0027] Carry out phase analysis to fly ash sample on X-ray diffractometer, obtain the X-ray diffraction spectrum figure of this sample ( image 3 ). No two diffraction peaks at 28.4° and 47.3° appear in the X-ray diffraction spectrum of the sample, and the sample is considered harmless. In the actual project, the concrete mixed with the fly ash has no defects, which proves the applicability of the method.

Embodiment 3

[0029] Take fly ash raw material from dry-mixed mortar plant.

[0030] Carry out phase analysis to fly ash sample on X-ray diffractometer, obtain the X-ray diffraction spectrum figure of this sample ( Figure 4). Two diffraction peaks of 28.4° and 47.3° appeared in the sample X-ray diffraction spectrum at the same time, it can be considered that the sample has the potential danger of causing concrete and mortar defects. Continue to use the gas measuring instrument to measure the gas volume (V) and gas generation duration (t) per unit mass of the sample in the NaOH alkaline solution with a pH of 13. The amount of NaOH alkaline solution is 400mL, and the fly ash is added The amount is 10g. During the whole process, the indoor ambient temperature, cooling water and interlayer water temperature were kept at 20°C. The obtained V and t were 0.13mL / g and 3h respectively, and V did not exceed the critical value of 0.20mL / g, so the sample was considered harmless. In the actual proj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com