Hydraulic pier shaft rebar machining formwork and pier shaft rebar construction technology

A pier body steel bar and construction technology technology, which is applied in the field of pier body steel bar processing, can solve the problems of long pier body construction period, harsh construction environment, and high construction conditions, and achieves the effects of flexible construction, avoiding high-altitude operations, and reducing processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

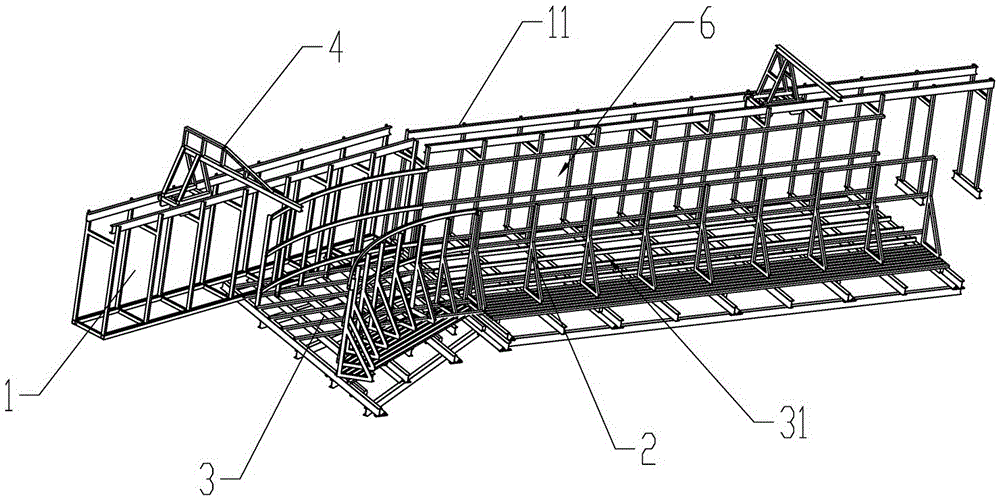

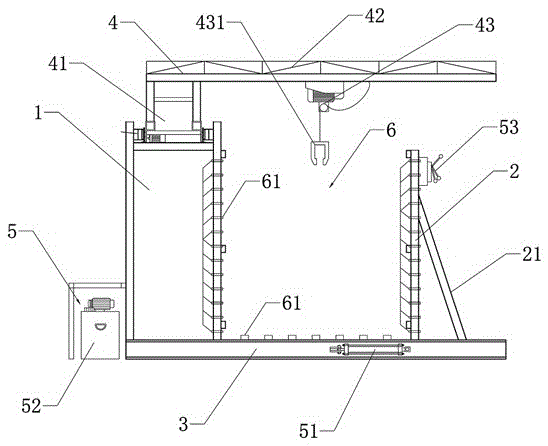

[0029] according to figure 1 , figure 2 As shown, a hydraulic pier body reinforcement processing formwork includes: first side formwork 1, second side formwork 2, bottom formwork 3, hoisting mechanism 4 and hydraulic system 5; first side formwork 1 and The second side formwork 2 is respectively located at both sides of the upper end of the bottom formwork 3, so that the first side formwork 1, the second side formwork 2 and the bottom formwork 3 form a processing area 6 with an open top; the first side formwork 1 The top is provided with a track 11 for guiding the movement of the hoisting system 4; one side of the bottom formwork 3 is fixedly connected with the first side formwork 1, and the other side is provided with a slide rail 31 for sliding the second side formwork 2, so that the second The side formwork 2 slides in a direction away from or close to the first side formwork 1 under the control of the hydraulic system 5; the hoisting mechanism 4 includes a crane 41 arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com