Concrete model

A technology of concrete and model, which is applied in the direction of earthwork drilling, formwork/formwork/work frame, wellbore lining, etc., can solve the problems of wasting wood resources, many seams, and heavy workload, so as to save wood resources and save wood. The effect of sewing and fast progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

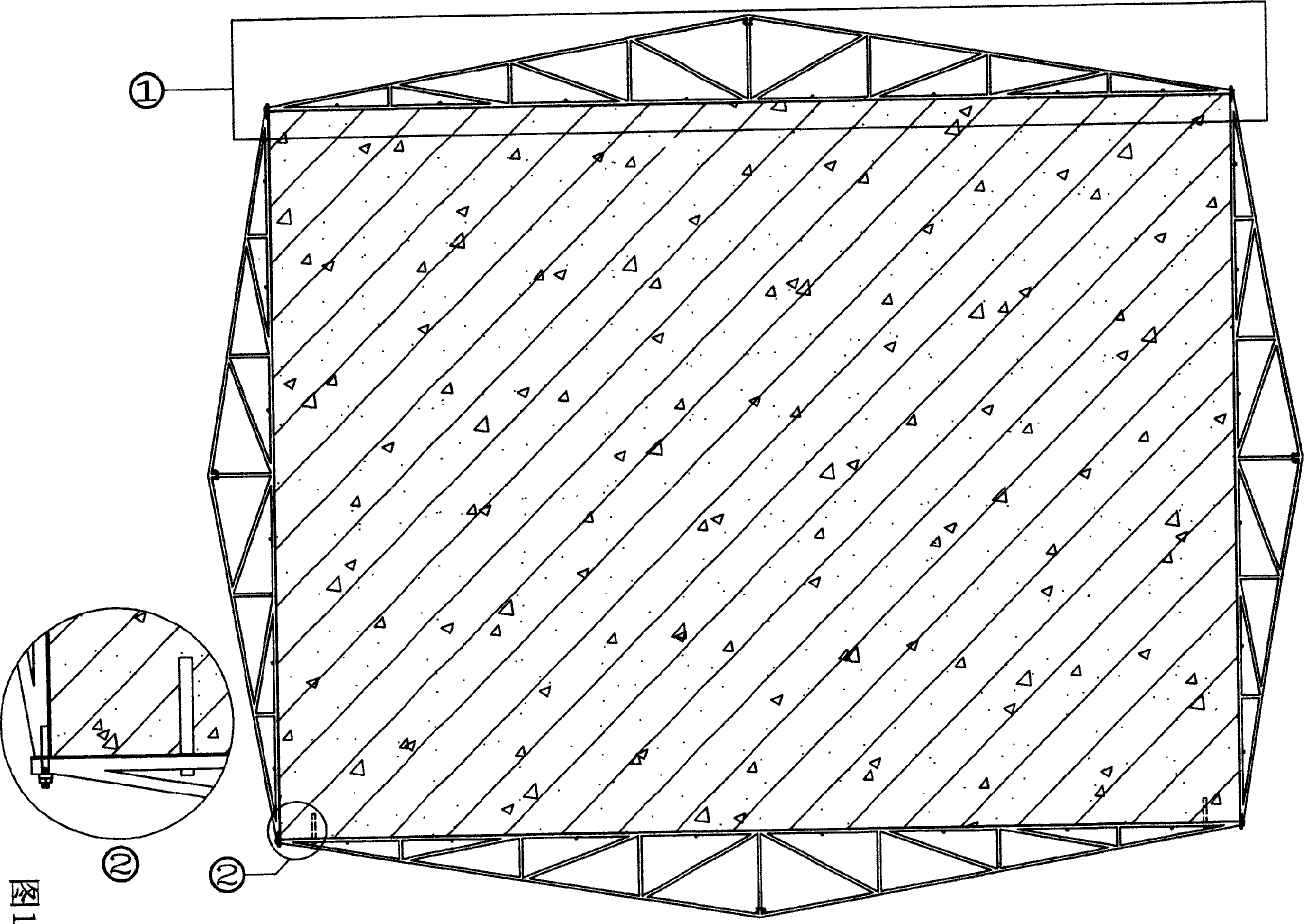

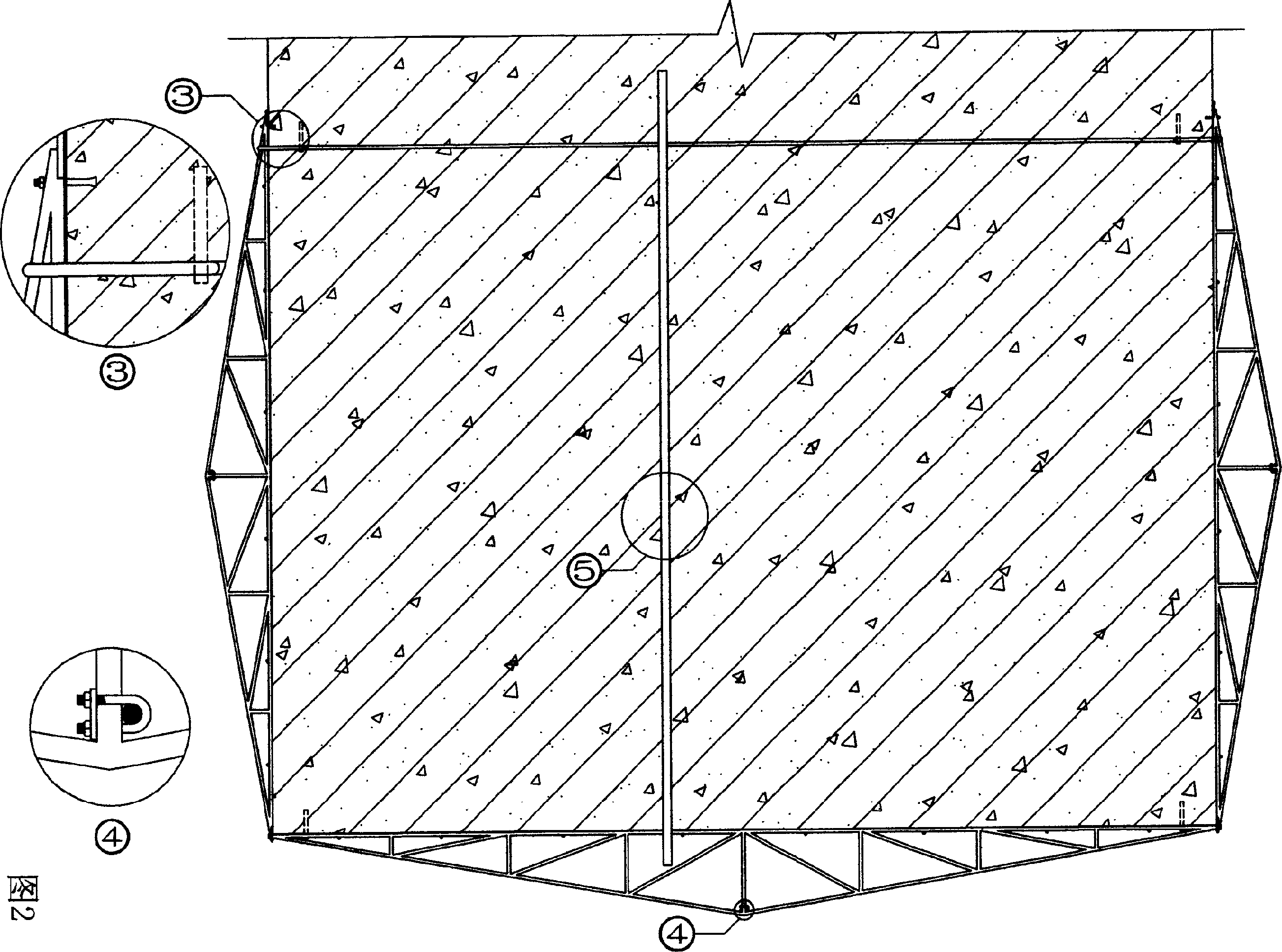

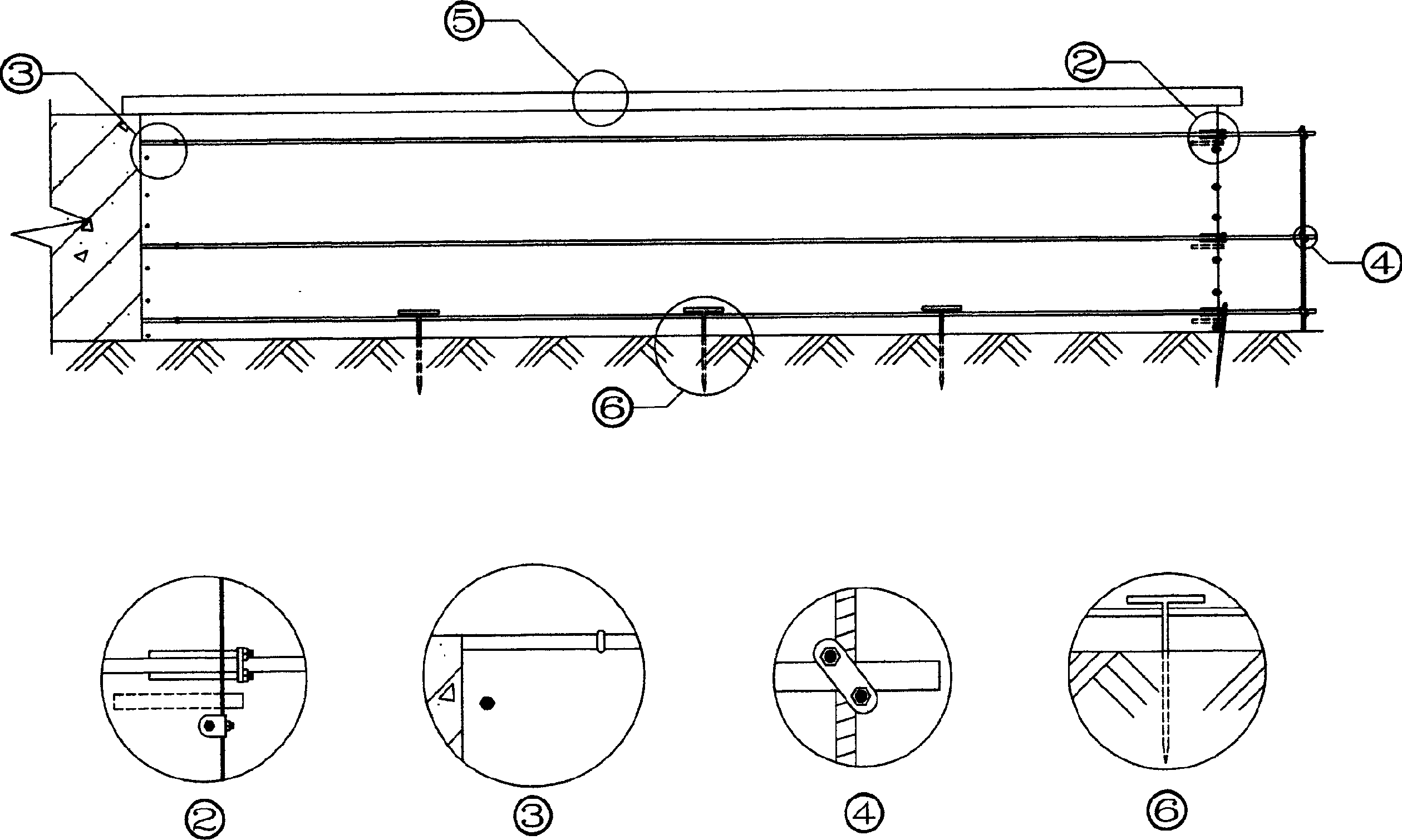

[0053] First, the factory produces various models according to specifications or culvert drawings, and then stacks them to the construction site for assembly.

[0054] Foundation assembly: fix the tripod (1) on the iron plate with screws, and fix the middle corner on the steel support (4) to form each template, connect the four corners with screws, and insert the embedded steel bars (2) into the holes of the iron plate. ), when assembling the second and later concrete models, fix one end of the two side molds on the previous piece of concrete with a bubble screw and a tie rod (the tie rod can also be replaced by multiple iron wires) (3), insert ground pins (6) ), brush a small amount of engine oil on the inner wall of the iron plate, stick a foam plate on the inner wall of the iron plate, and fill the concrete with a ruler to level the surface of the concrete (5).

[0055] Foundation transfer: remove the back template (1), when removing the second and subsequent concrete models, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com