Intelligent control method of PTA particle size in fine terephthalic acid production device

A technology of intelligent control and particle size, applied in the method of granulating raw materials, preparation of carboxylate, chemical instruments and methods, etc., can solve problems such as affecting product quality, slowness, and inability to measure particle size online.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

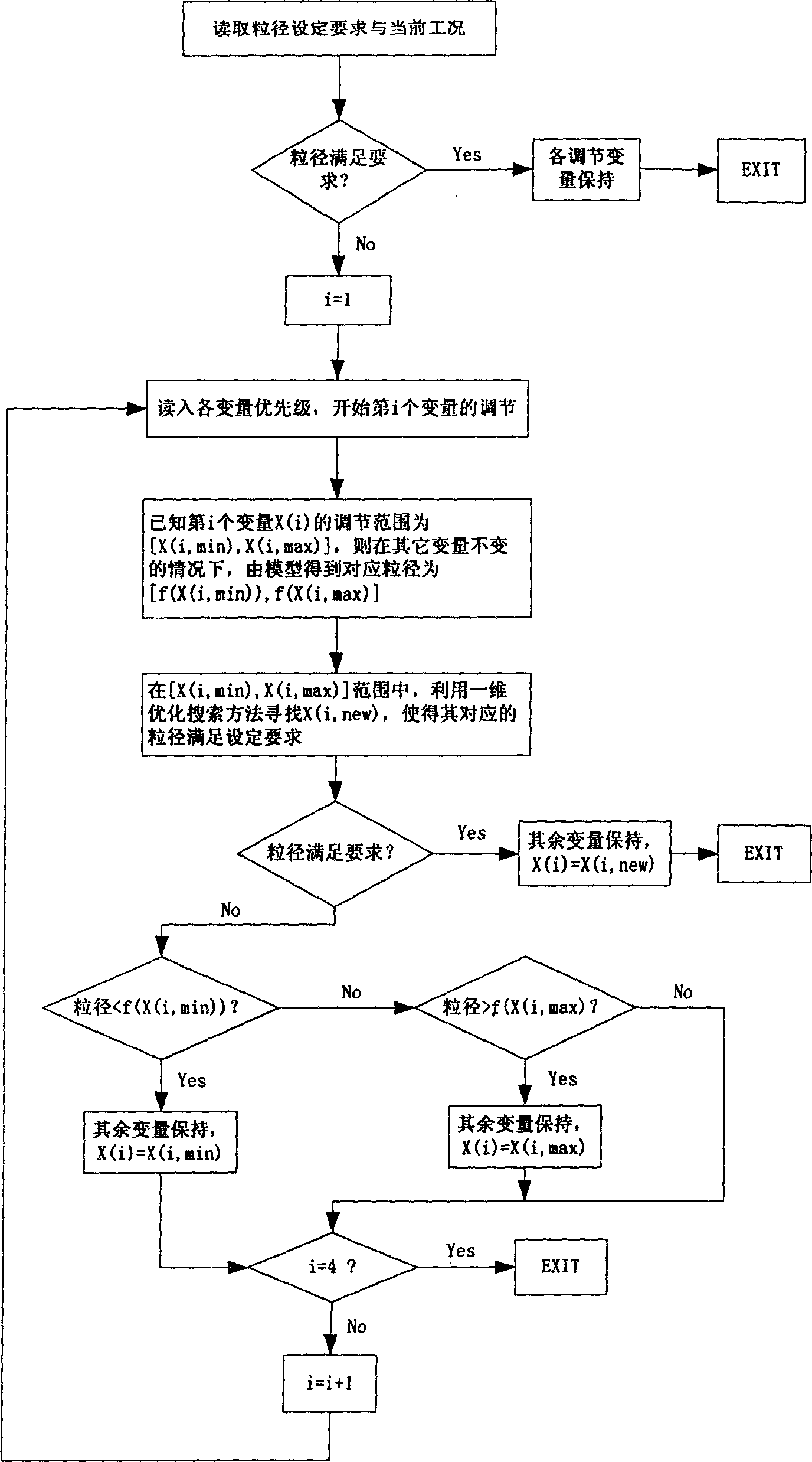

[0030] Below in conjunction with accompanying drawing and by embodiment the present invention will be further described:

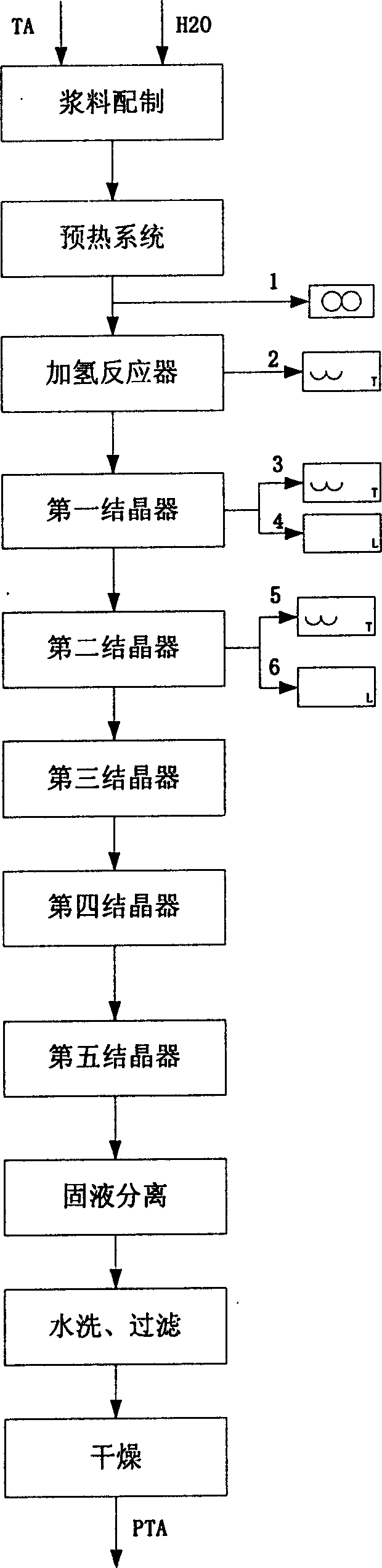

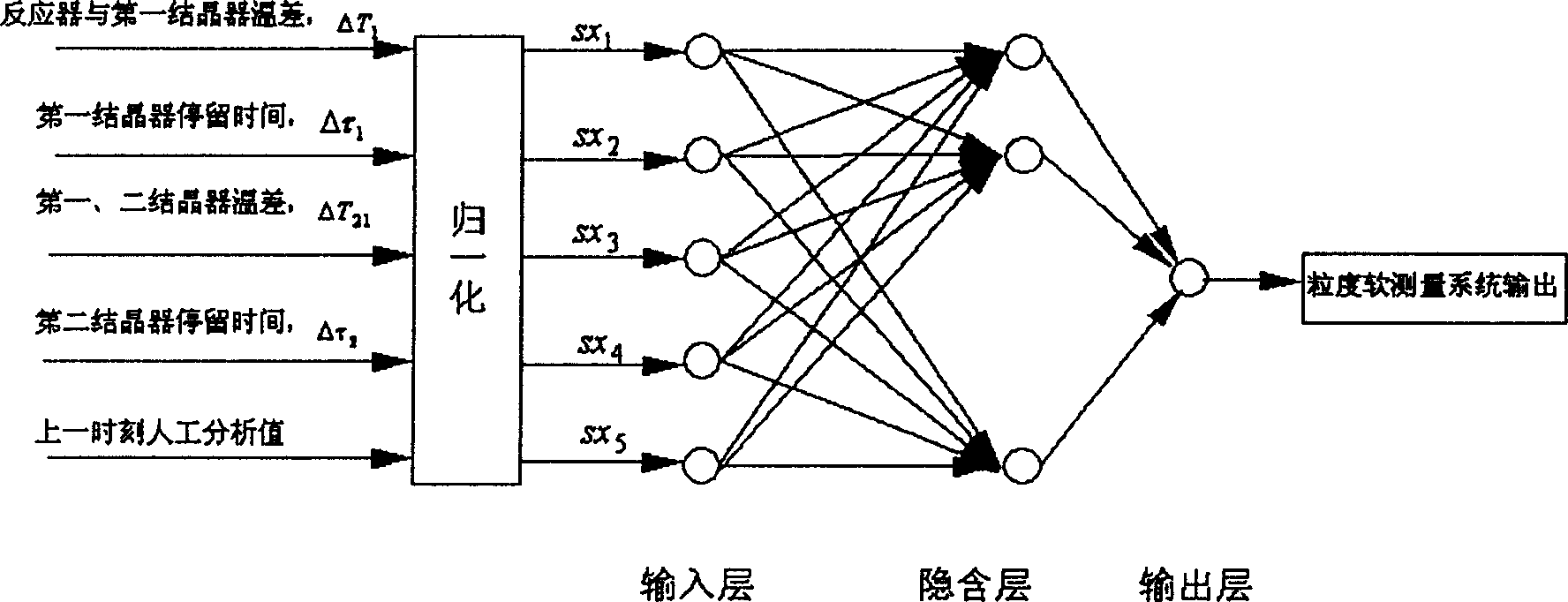

[0031] According to the load flow and temperature of the hydrogenation reactor, the temperature and liquid level of the first crystallizer, the temperature and liquid level of the second crystallizer, and the particle size analysis value at the previous moment, through a computer system (such as a DCS system or a real-time database) , to obtain the load flow and temperature value of the hydrogenation reactor one hour before the current moment, the temperature and liquid level value of the first crystallizer half an hour before the current moment, and the temperature and liquid level value of the second crystallizer at the current moment.

[0032] Through historical data records, select 100 sets of data of the above variables, use equation (1) to obtain the input data of the neural network soft sensor system, and perform normalization processing, and use the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com