Organic luminous display apparatus and manufacturing method thereof

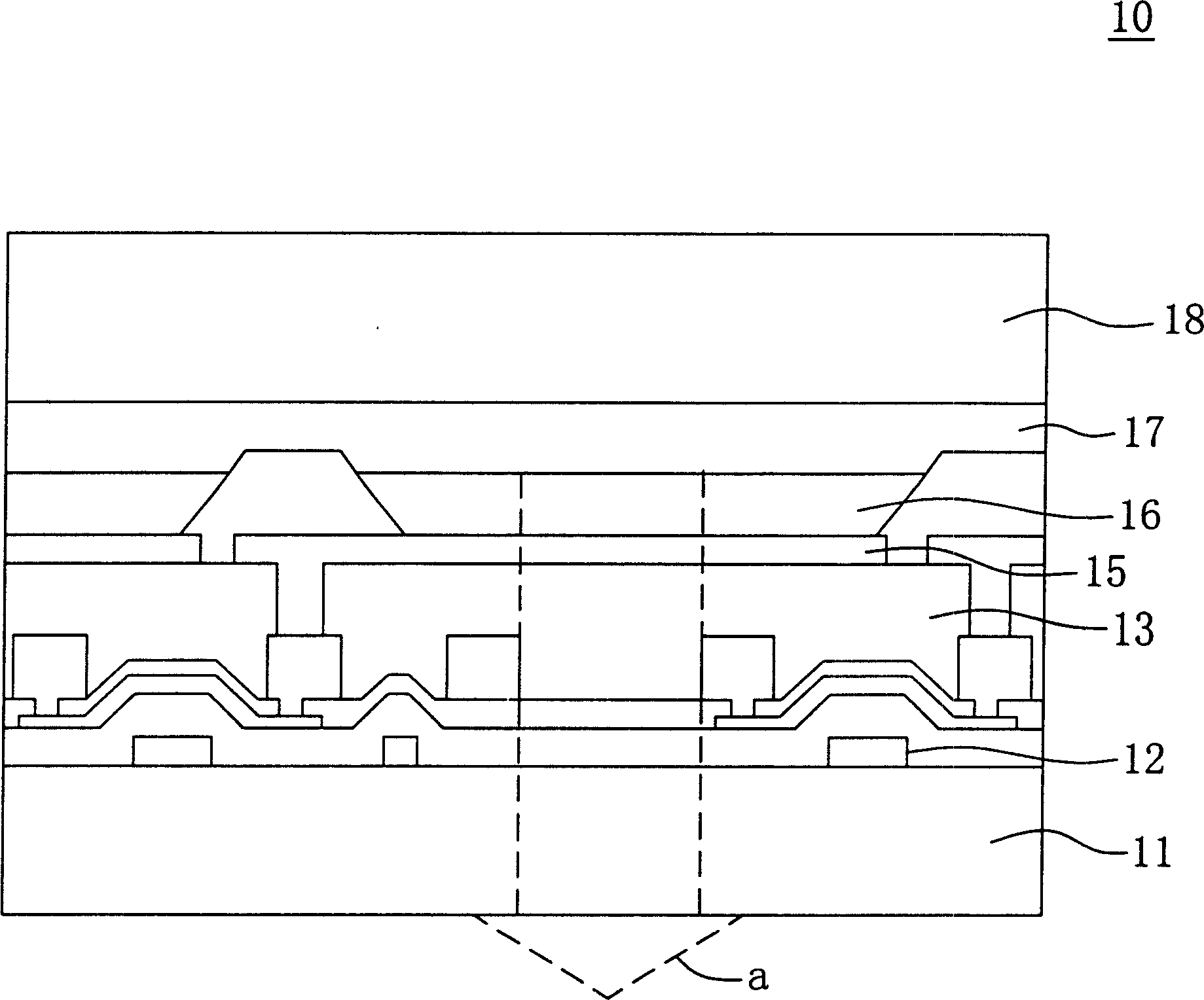

A light-emitting display, organic technology, applied in the field of organic light-emitting display devices, can solve problems such as affecting the quality of the display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

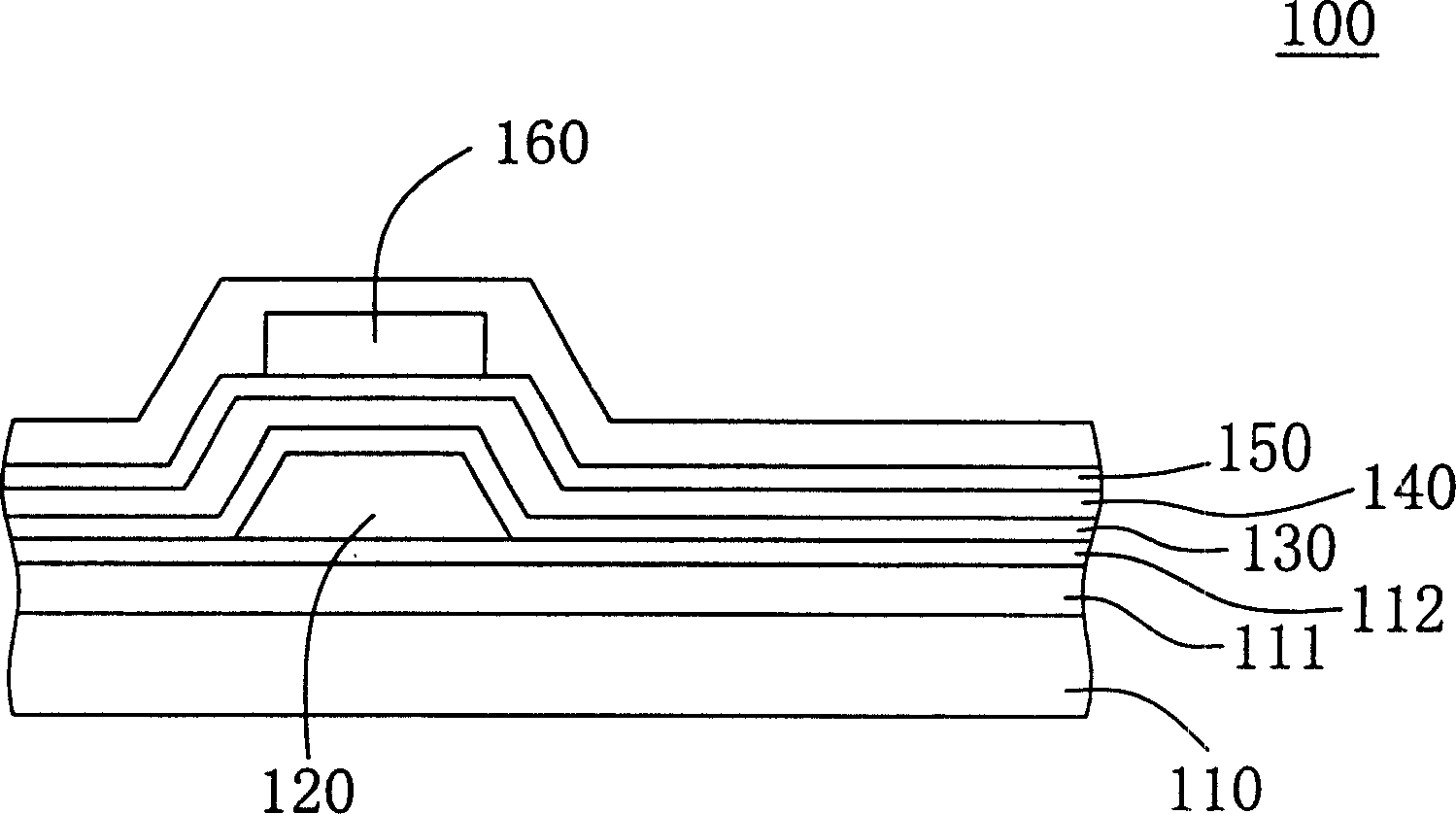

[0017] Please refer to figure 2 , which shows a side view of an organic light emitting display unit according to Embodiment 1 of the present invention. In the organic light emitting display unit 100, a reflective layer 111 is formed on the substrate 110, the thin film transistor 120 is disposed on the reflective layer 111; the anode 130 is disposed on the thin film transistor 120 and the substrate 110; the organic light emitting structure 140 is disposed on the anode 130; 150 is disposed on the organic light emitting structure 140 ; the bus line 160 is formed on the cathode 150 and is electrically connected to the cathode 150 to reduce the resistance of the cathode 150 .

[0018] In the organic light-emitting display unit 100, the cathode 150 is made of a light-transmitting material, such as a layer of thin-film metal, a layer of indium tin oxide (ITO) or a layer of thin-film metal and at least one layer of indium. A combination of tin oxides. In addition, the thickness o...

Embodiment 2

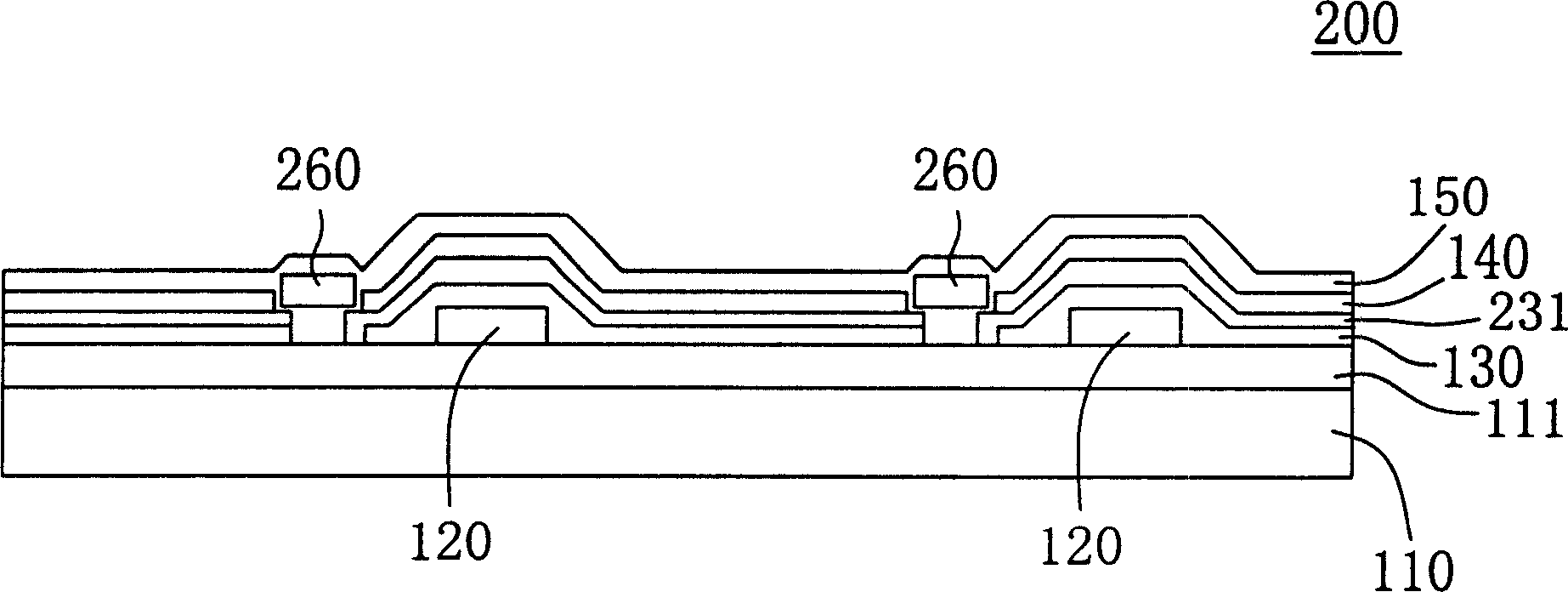

[0023] The components of the organic light emitting display unit of this embodiment are the same as those of the first embodiment, but the relative positions of formation are different, and the manufacturing process is also different. This embodiment will continue to use the component numbers of the first embodiment.

[0024] Please refer to image 3 , which shows a side view of an organic light emitting display unit according to Embodiment 2 of the present invention. In the organic light emitting display unit 200 , a protective layer 231 is disposed between the anode 140 and the bus line 260 , so that the anode 140 is adjacent to the bus line 260 but is not electrically connected. In addition, the bus line 260 is disposed on the sides of the organic light emitting structure 140 and the cathode 150 , and is located between two organic light emitting units to form a black matrix.

[0025] In an actual manufacturing process, the manufacturing method of the organic light emitti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com