Conical disc type superheated steam drying device and method suitable for granular materials

A granular material, superheated steam technology, applied in the direction of drying gas arrangement, non-progressive dryer, heating to dry solid materials, etc., can solve the problem of uniform drying of particles with different particle sizes, to avoid pressure drop, transmission High heat and mass transfer efficiency and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

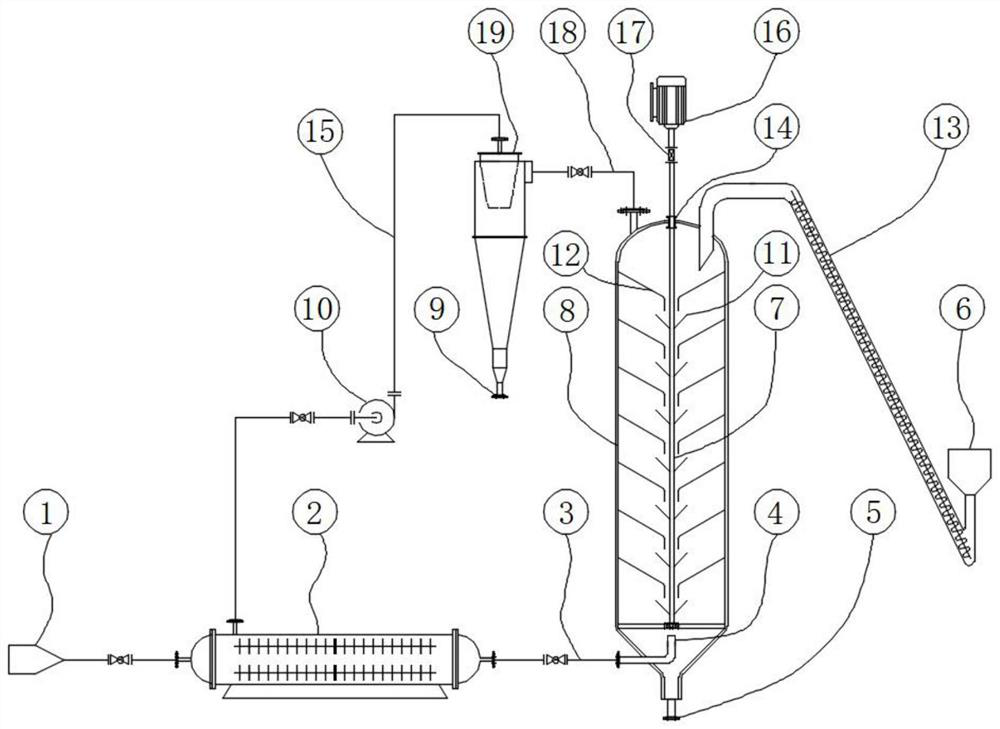

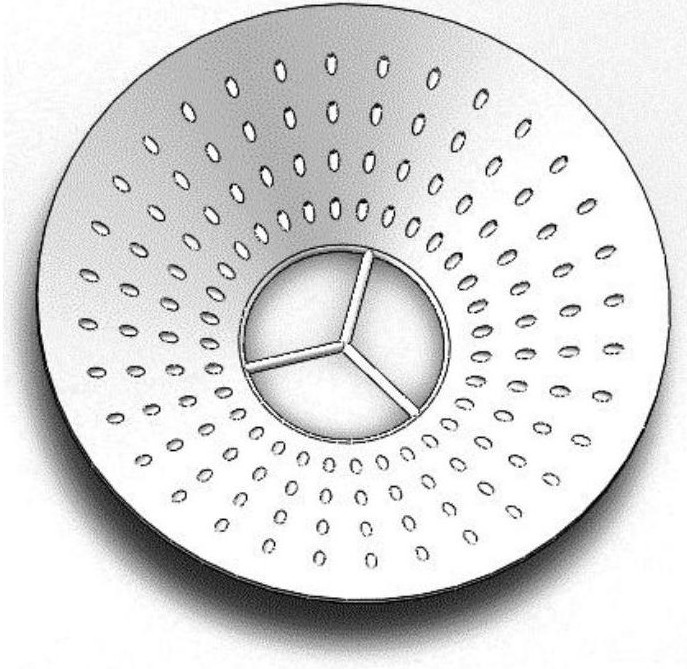

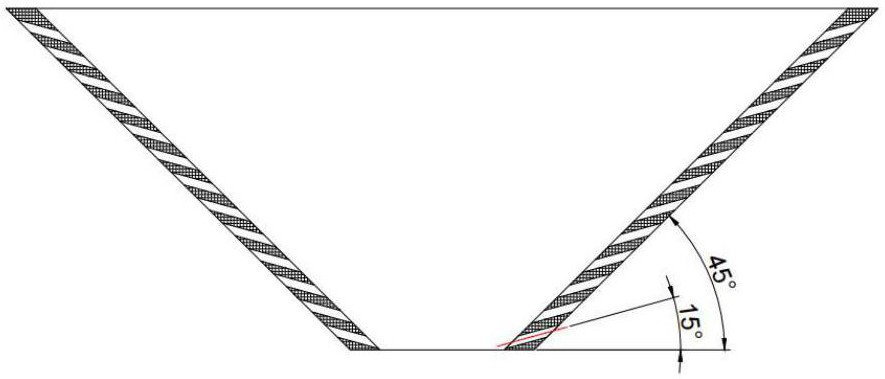

[0035] A cone-disc superheated steam drying device suitable for granular materials, its innovation is that it includes a steam superheater 2 and a dryer 8, saturated steam is passed into the steam superheater 2 through a steam inlet 1, and the The superheated steam produced by the steam superheater 2 is transported to the lower end of the dryer 8 through the hot steam distributor 4 along the steam delivery line 3, and the top of the dryer 8 is connected with a screw feeder 13, and the screw feeder 13 The end of the dryer is connected to the material inlet 6, and a rotating shaft 7 is installed along the center line in the dryer. The lower end of the rotating shaft 7 is connected to the collar provided in the dryer 8. The rotating shaft 7 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com