Reversing gear looking mechanism of engine for motorcycle

A technology of engine and reverse gear lock, applied in mechanical equipment, vehicle parts, transmission control and other directions, can solve the problems of unsafe hidden danger, unclear memory, driver's misoperation, etc., to achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

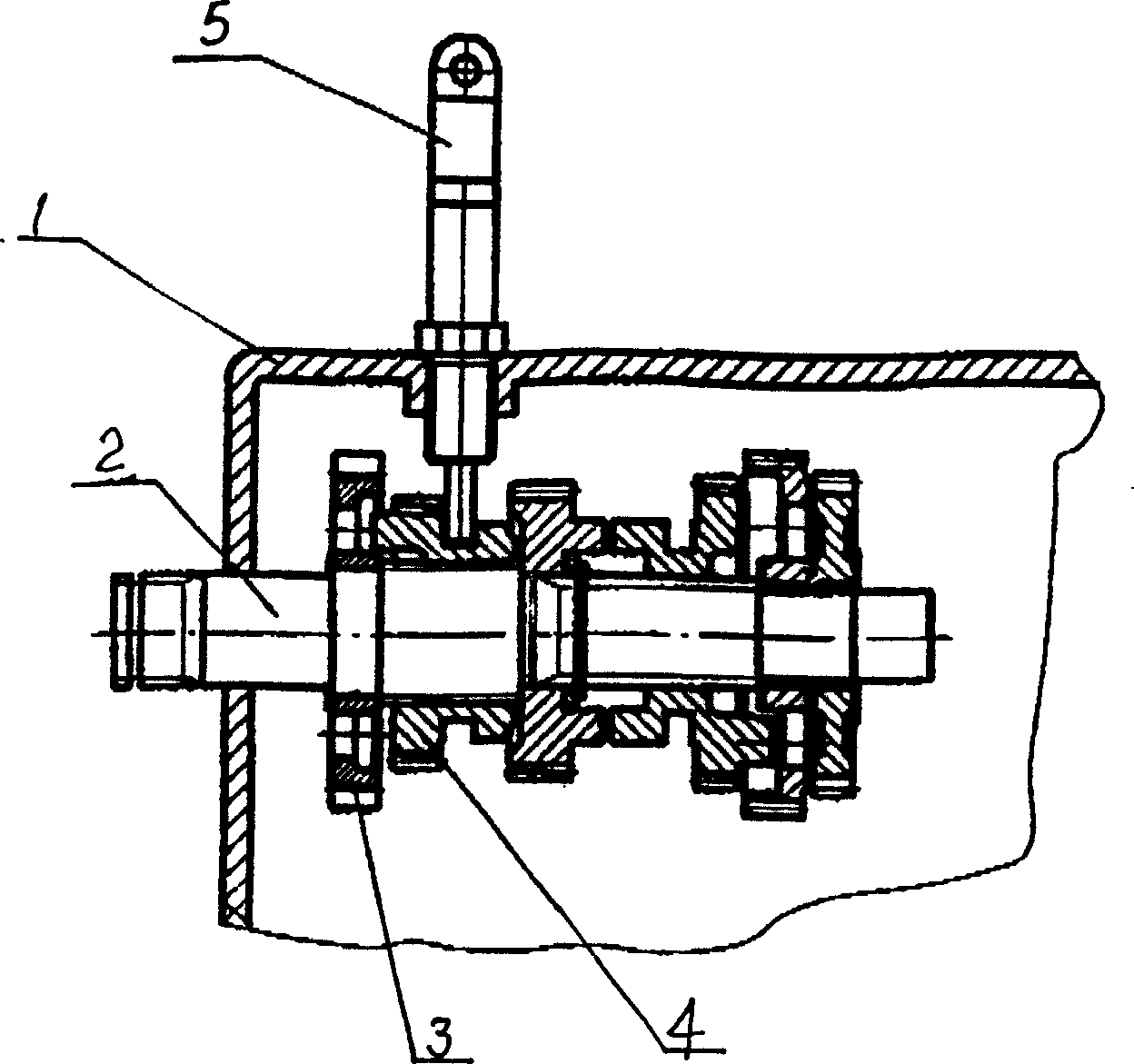

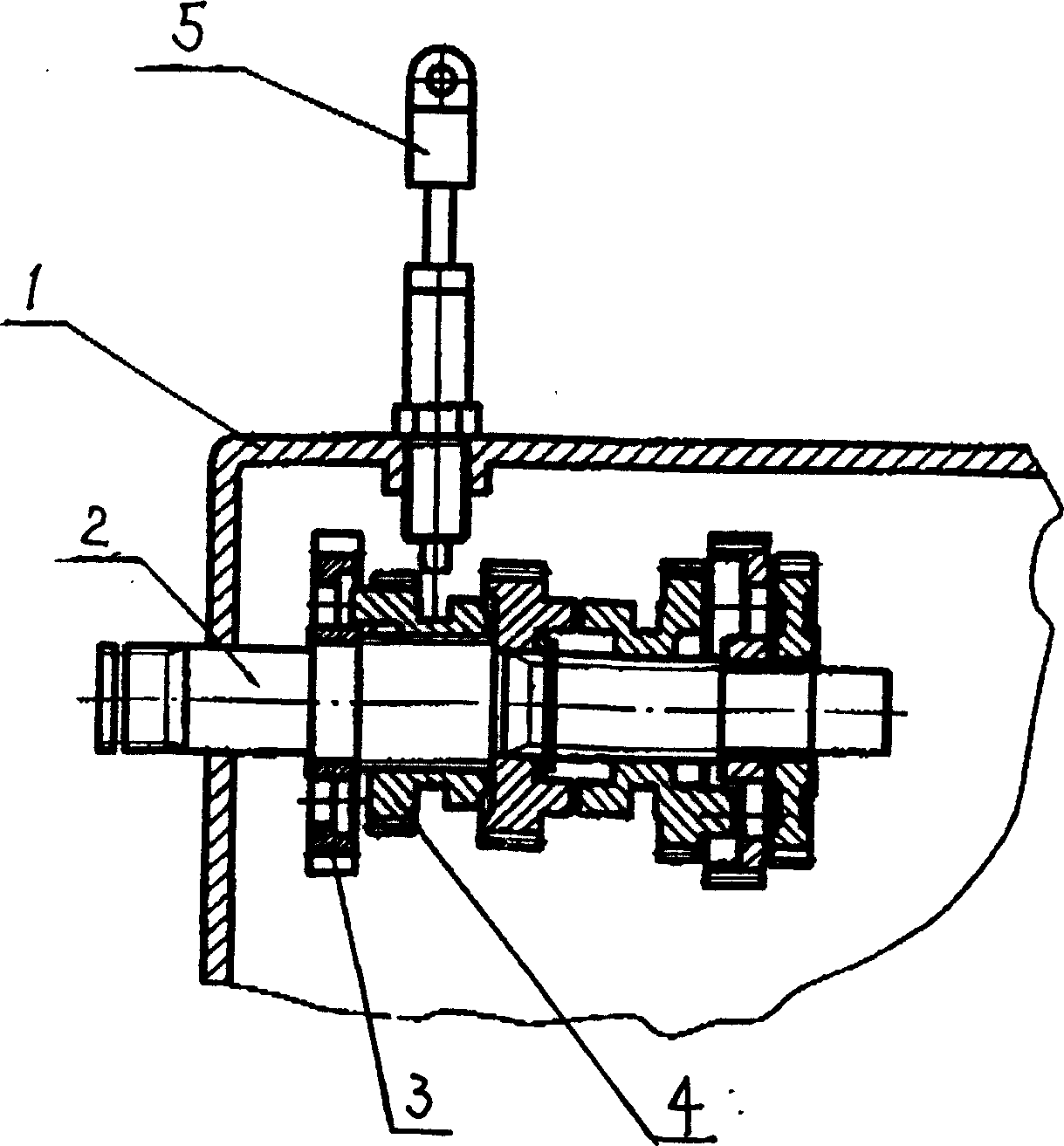

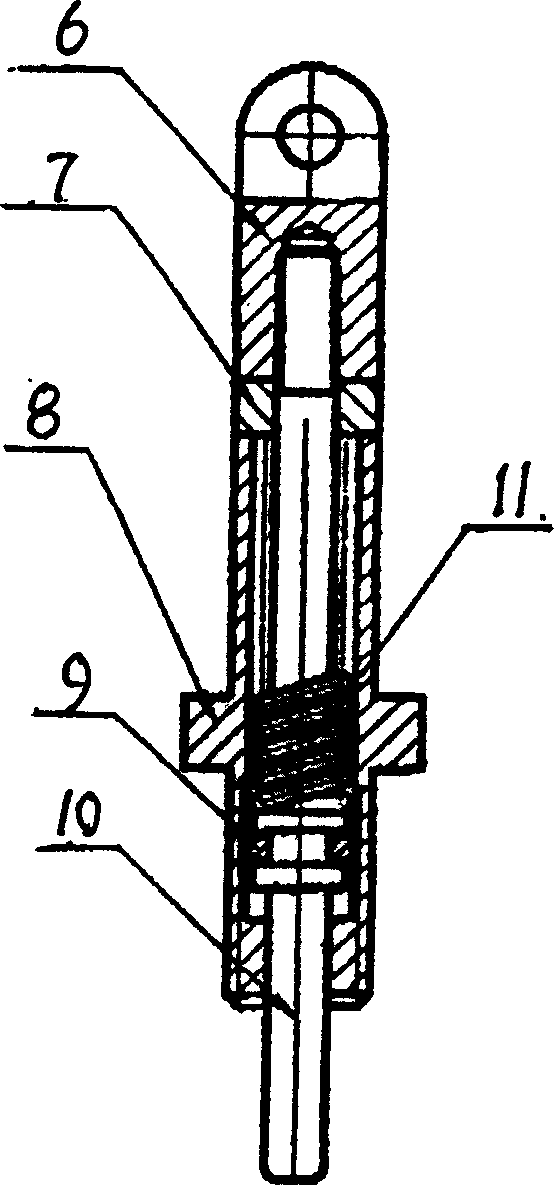

[0010] please see figure 1 , figure 2 , image 3 , the present invention is made up of starting left crankcase body 1, engine countershaft 2, reverse gear 3, fifth gear 4, reverse gear locking mechanism 5, wherein engine left crankcase body 1, countershaft 2 and are installed on the countershaft The reverse gear 3 and the fifth gear 4 on 2 are identical in structure with the prior art, but the difference is that the locking mechanism 5 installed on the engine crankcase 1 consists of a lock housing 8, an oil seal ring 9, a lock pin 10, a back Position spring 11, plug 7, handle 6, wherein the return spring 11 and oil seal ring 9 are set on the lock pin 10, and are located in the lock case 8, and one end of the lock pin 10 installed in the lock case 8 protrudes out of the lock case 8, the other end passes through the plug 7 and is fastened in the handle 6 (threaded connection can be used); the end of the lock pin 10 extending out of the lock housing 8 extends into the left cra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com