Ultrosonic on-line positioning method of mobile mini robot in duct

A technology of micro-robots and positioning methods, applied in the direction of sound wave re-radiation, instruments, manipulators, etc., can solve the problems of low reliability, poor safety performance, complex structure, etc., and achieve low cost, high reflectivity, and simple devices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

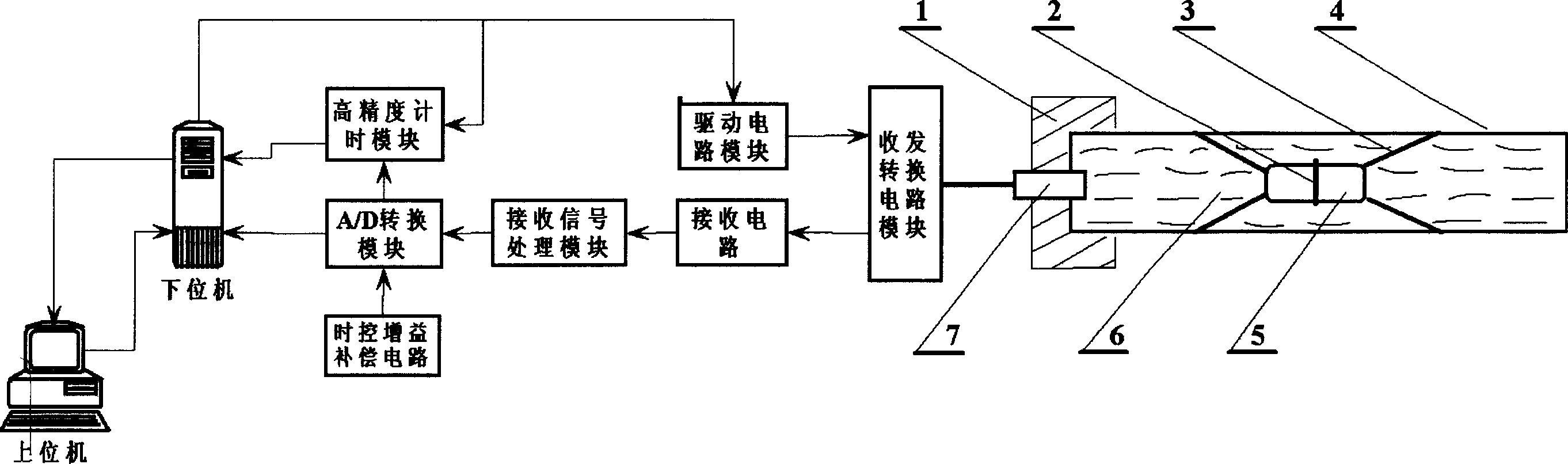

[0026] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

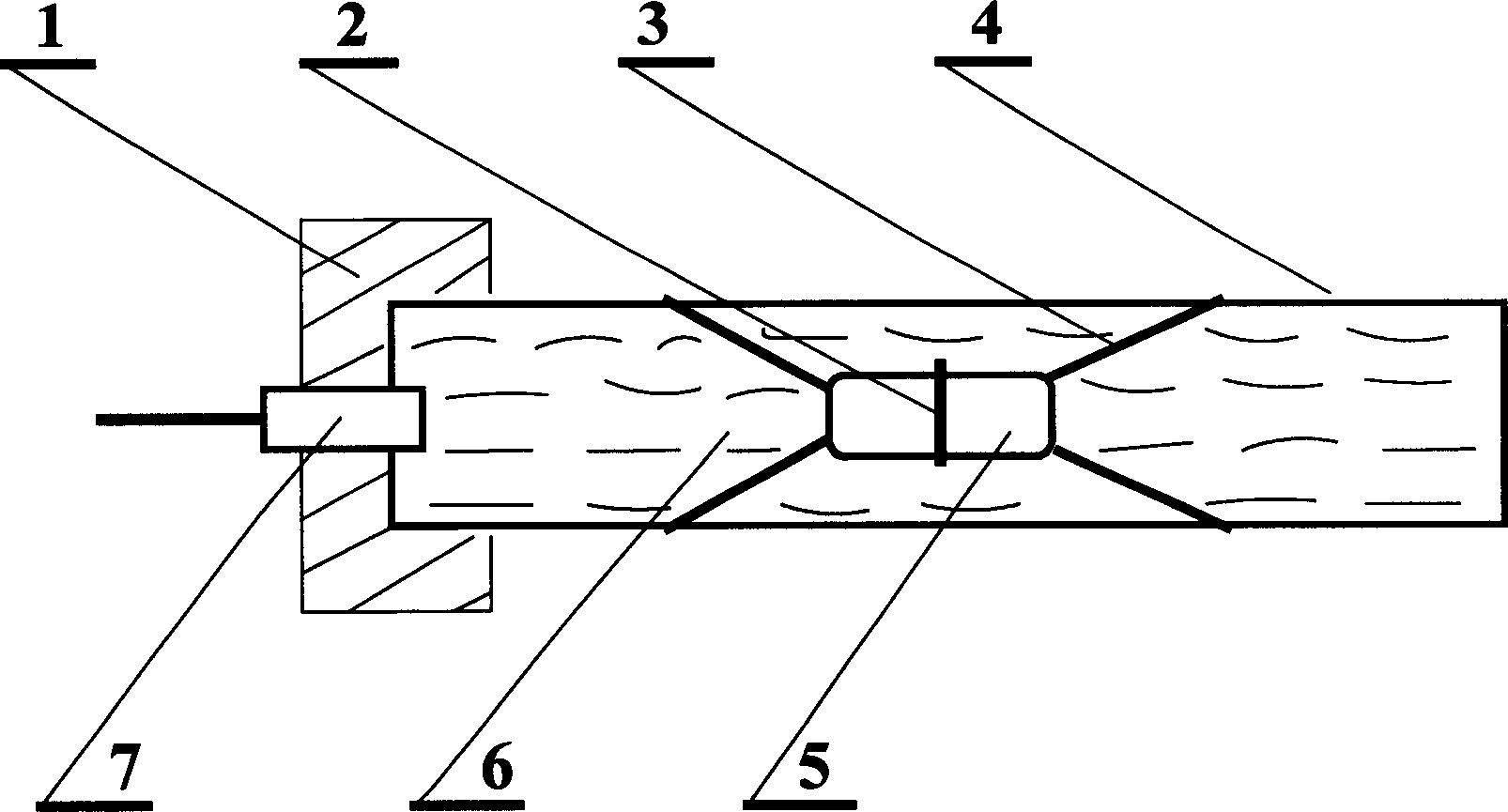

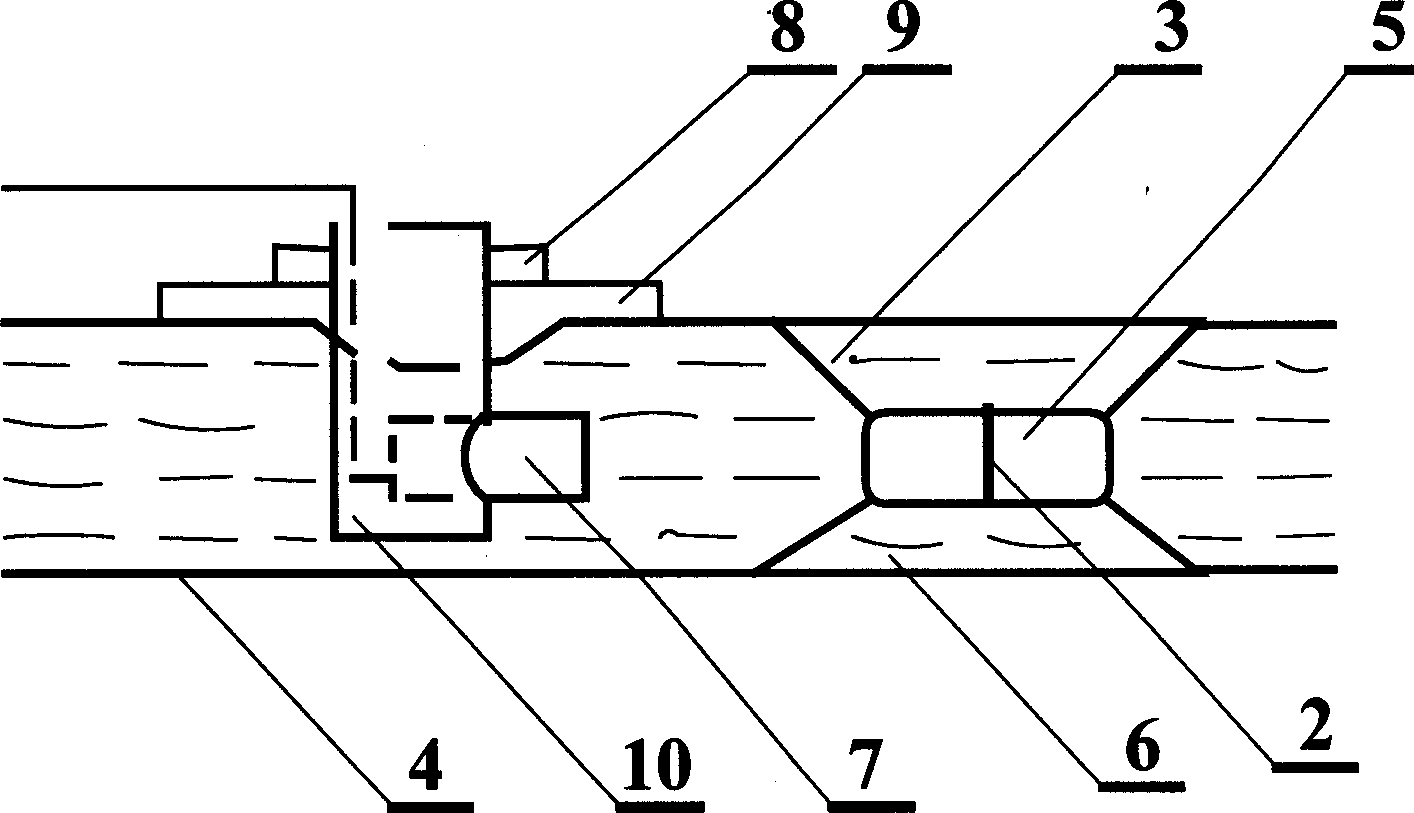

[0027] First of all, according to different measurement occasions, to choose figure 2 with image 3 Two sensor mounting structures. When it is possible to install the ultrasonic sensor at one end of the pipe, the first configuration is used, otherwise the second configuration is used. The following uses the first structure to illustrate.

[0028] Determine the size of its ultrasonic signal reflectivity according to the material and structure of the robot body 5. If the reflectivity is small, the structure of the robot body can be adjusted by adding small substances with large impedance 2 to improve the reflectivity of the ultrasonic signal. The type transceiver integrated ultrasonic sensor 7 is fixed on the sealed positioning plug 1, and then one end of the robot walking pipeline 4 is well sealed with the sealed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com