Novel pillowcase processing technology

A new process and processing technology, applied in the new process field of bedding production, can solve the problems of production environment pollution, high labor intensity of workers, and difficulty in meeting hygiene requirements, and achieve the effect of reducing costs, improving production environment and labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

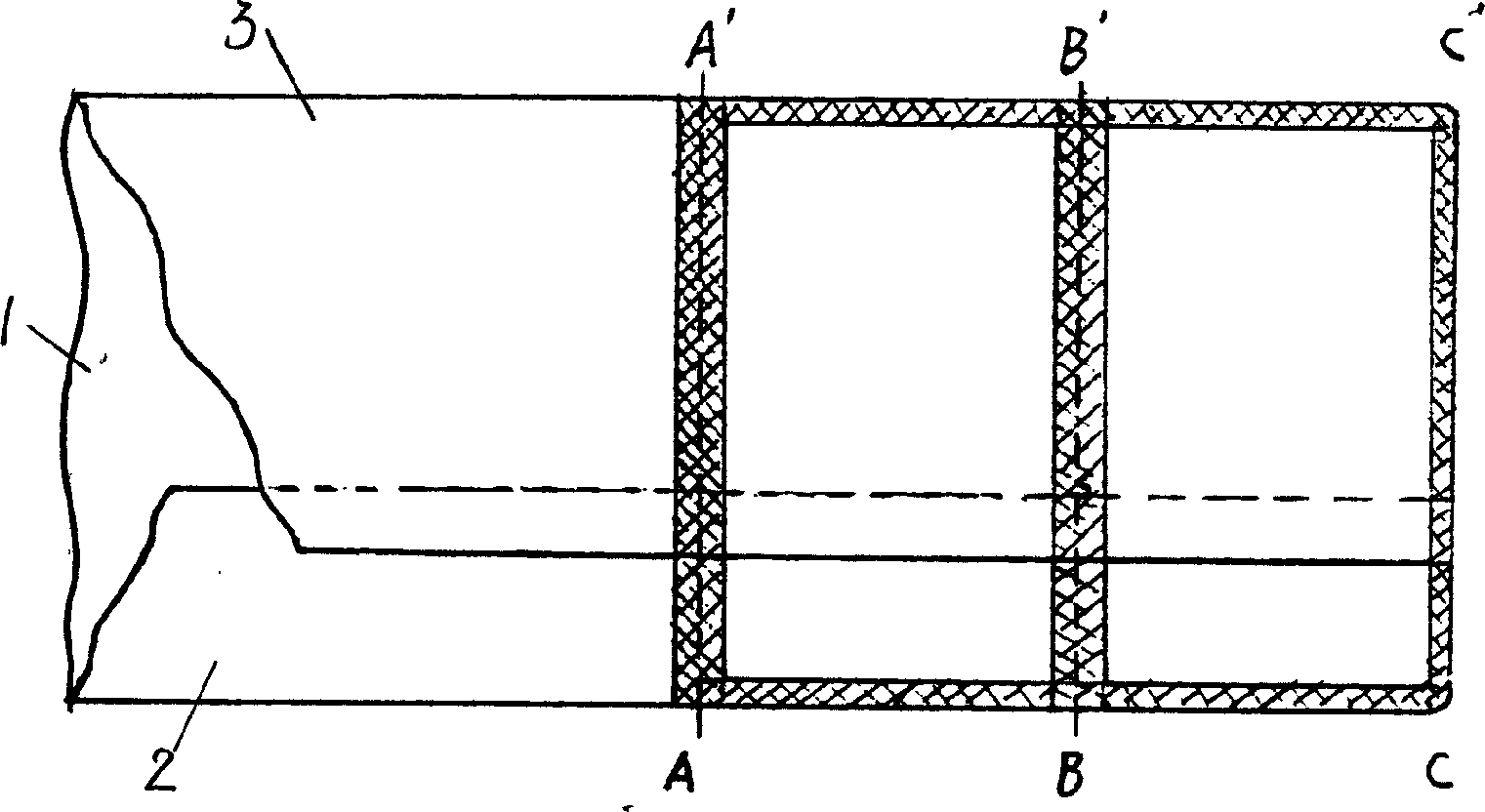

[0009] Example 1: Press figure 1 In the direction of A→B→C motion trajectory, the fabric is released from the discharge shaft, and the three-layer fabrics 1, 2 and 3 of unequal width are formed after folding, and the three-layer fabric is perpendicular to the plane in the AA'BB' area. Four-side butt welding, in CC', the symmetrical center line AA'BB' is cut on the weld seam, and the standard size pillowcase can be automatically and continuously produced by the circular mechanical action of fabric butt welding→weld seam cutting.

Embodiment 2

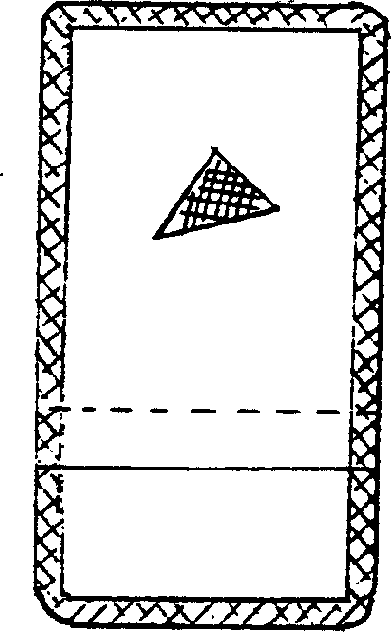

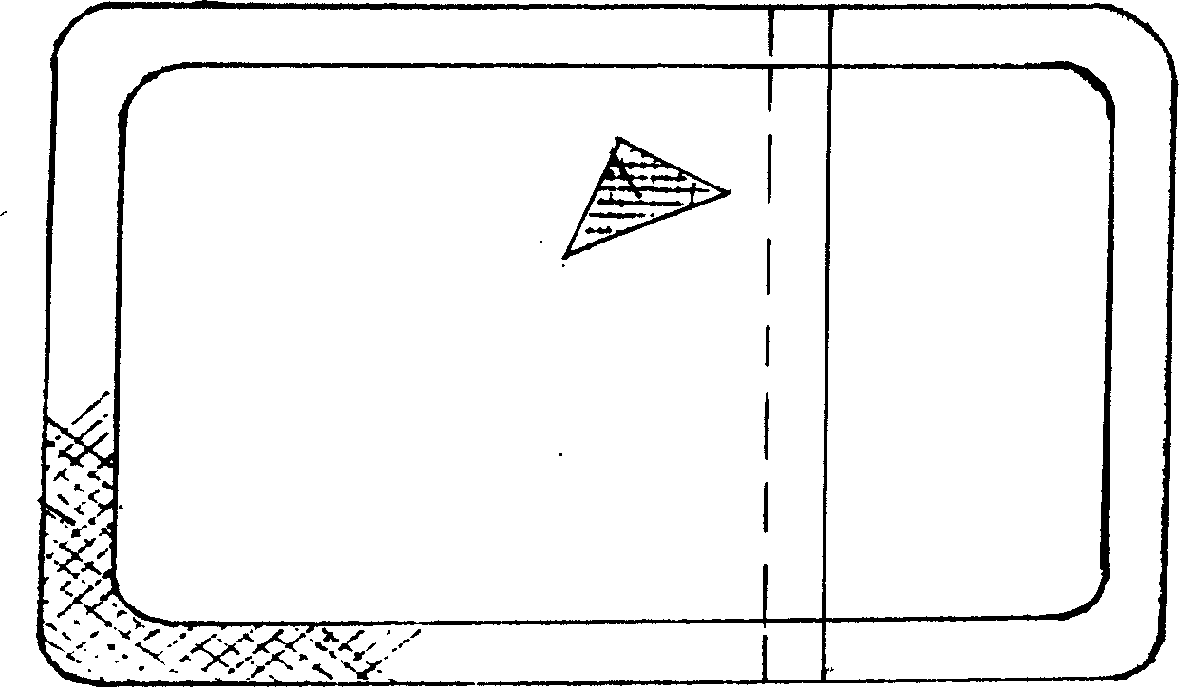

[0010] Example 2: Press figure 2 In the direction of A→B→C motion trajectory, three layers of unequal width fabrics 1, 2 and 3 are released from the three feeding axes synchronously, and the three layers of fabrics are welded perpendicular to the plane in the AA'BB' area. In CC', the symmetrical center line AA'BB' of the weld is cut, and the circular mechanical action of fabric butt welding→weld cutting can automatically and continuously produce pillowcases of standard size (see image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com