Fastening type lightgage steel joist

A light steel keel and snap-on technology, applied in the field of architectural decorative components, can solve the problems of loose keel connection, affecting the progress of the project, slow construction speed, etc., to ensure the quality of the project, reduce the cost of the project, and improve the construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

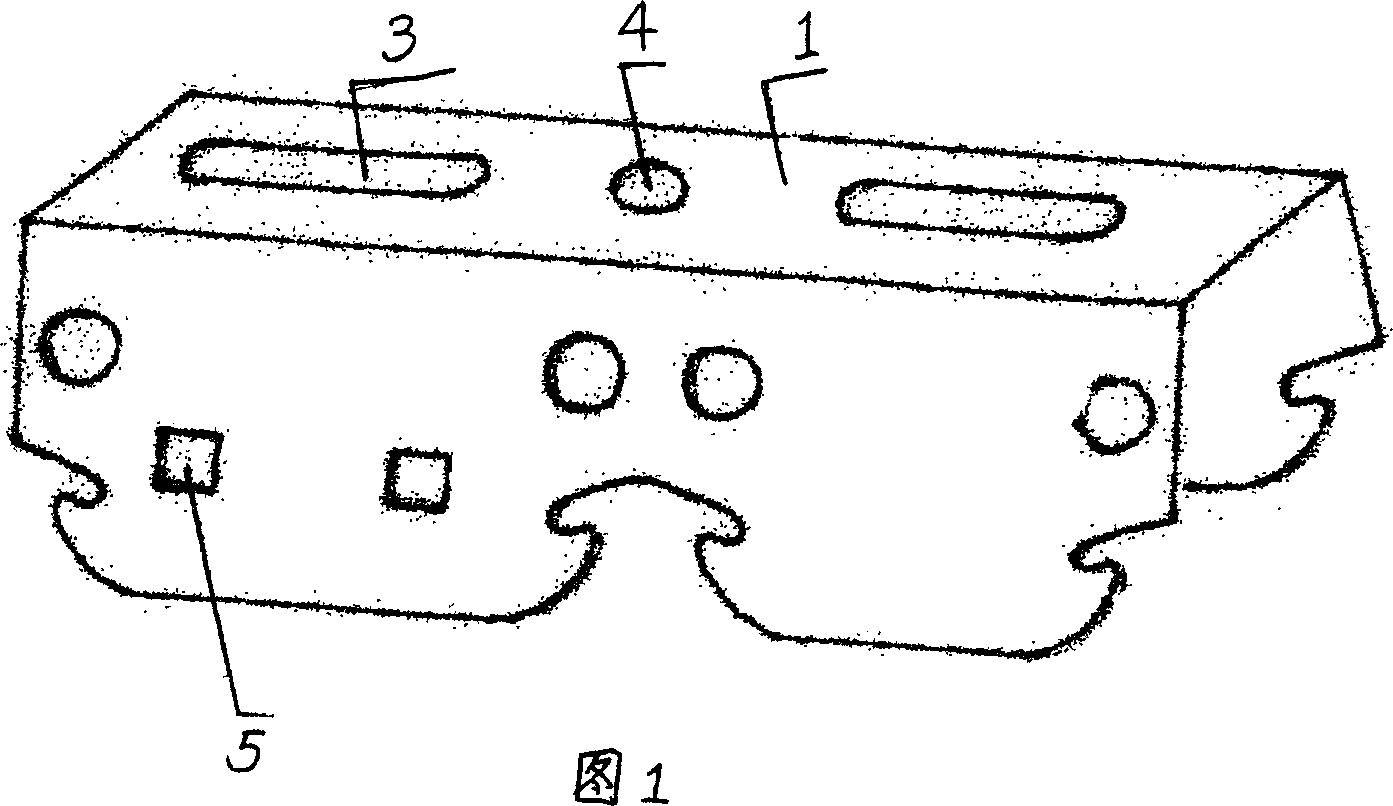

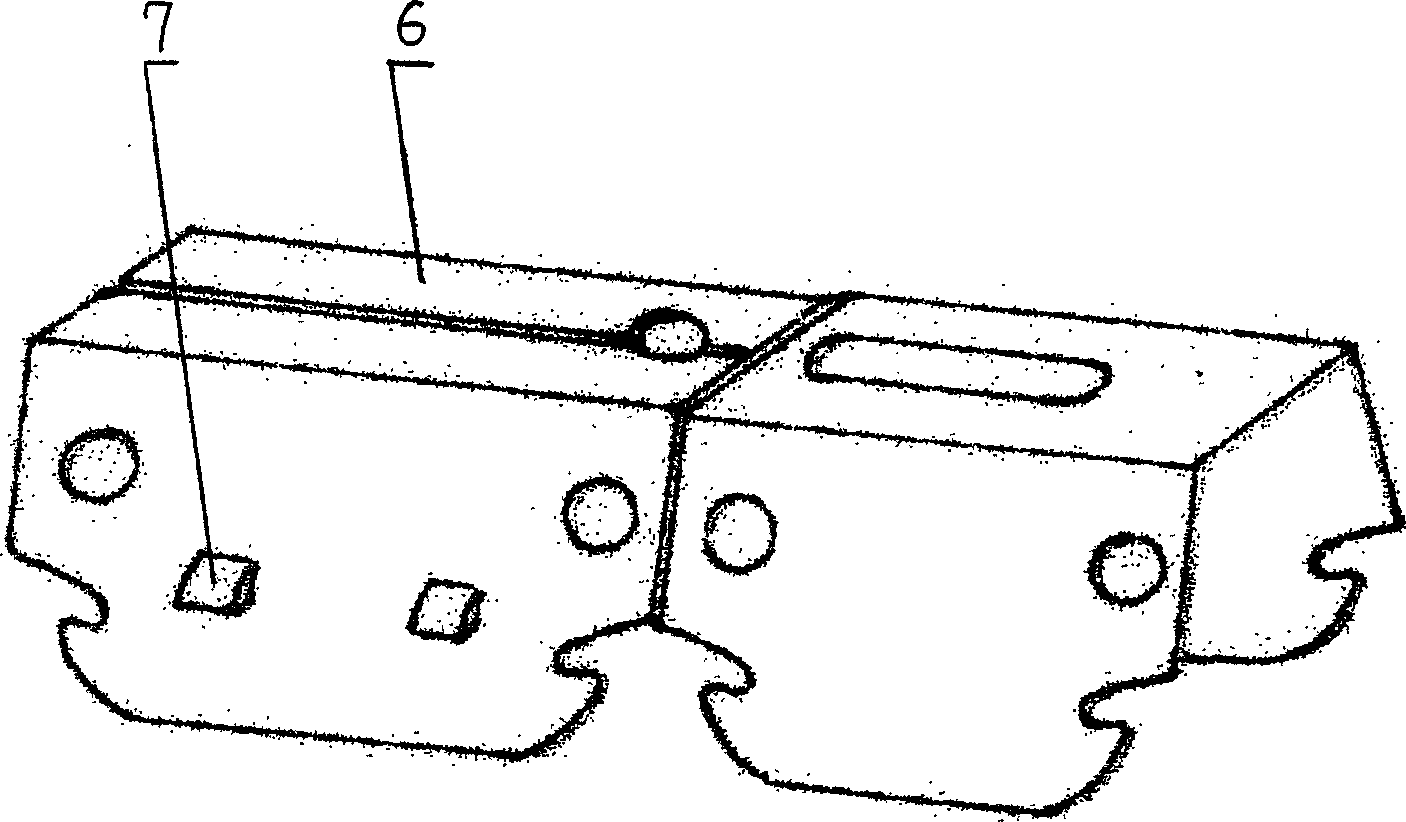

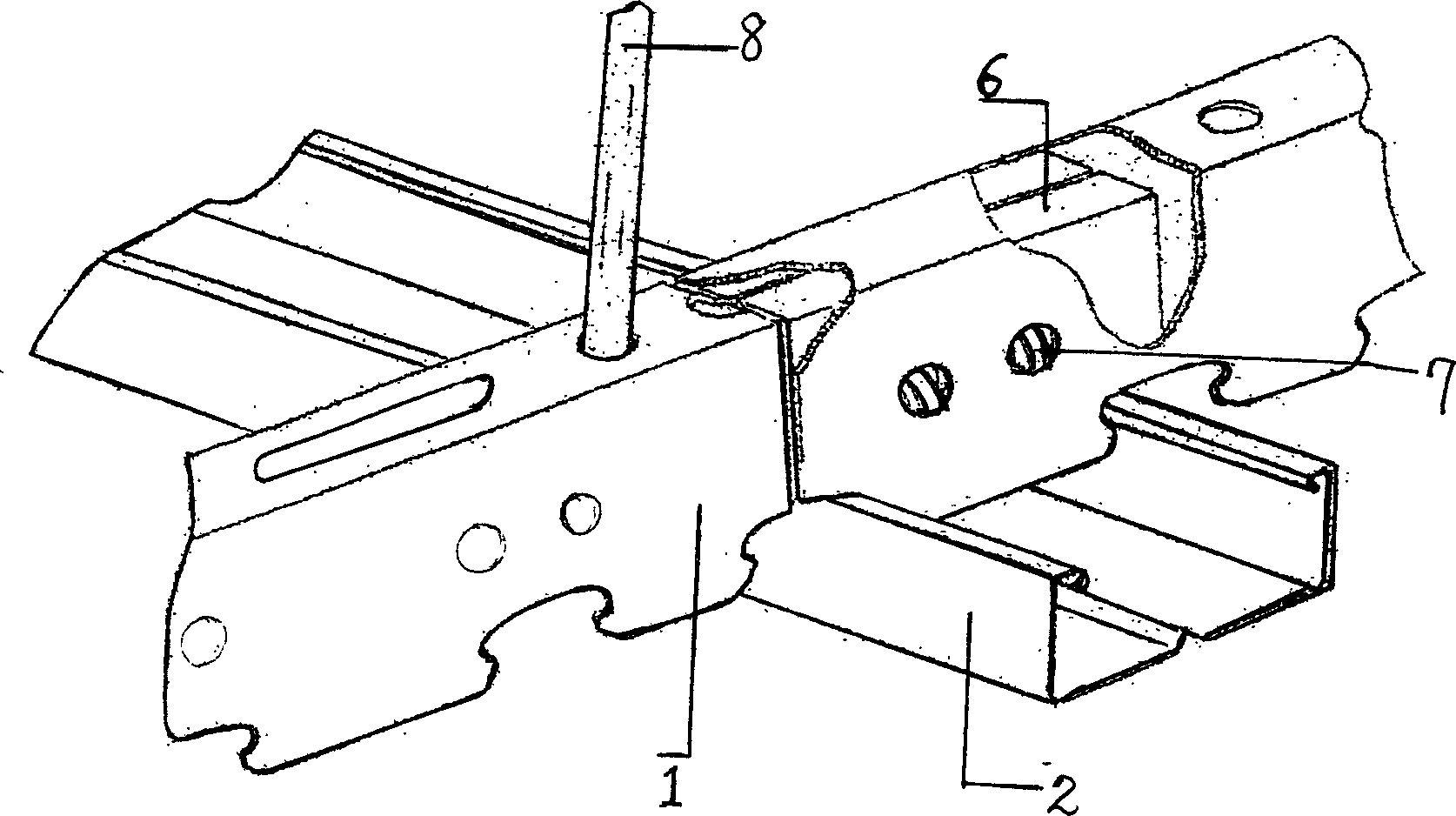

[0012] As shown in the above figures, the present invention is mainly composed of a main keel 1, an auxiliary keel 2, a suspender 8 and other components, and the two main keels (that is, the first main keel and the second main keel) are connected by a main keel joint 6 . The cross-section of the joint of the main keel 1 is in the form of an angle, and at the same time, two hooks 7 protruding outwards and inclined in one direction are arranged on the end faces of the left and right sides of the joint, that is, double hooks. The two sides of the connector at the other end are respectively provided with locking holes 5 for locking with the hooks 7 . When connecting, the first main keel joint 6 is connected to the clamping hole end of the first main keel, and at the same time, the hooks 7 on both sides of the main keel joint 6 and the clamping holes 5 on both sides of the first main keel are effectively elastically connected by steel plates . Due to the double hook structure, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com