High pressure container and manufacture thereof

A high-pressure vessel and metal technology, which is applied in the manufacture of vessel structures, pressure vessels, and outer walls of vessel structures, etc., can solve the problem of fatigue of metal linings, and achieve the effect of preventing axial sliding and preventing radial sliding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

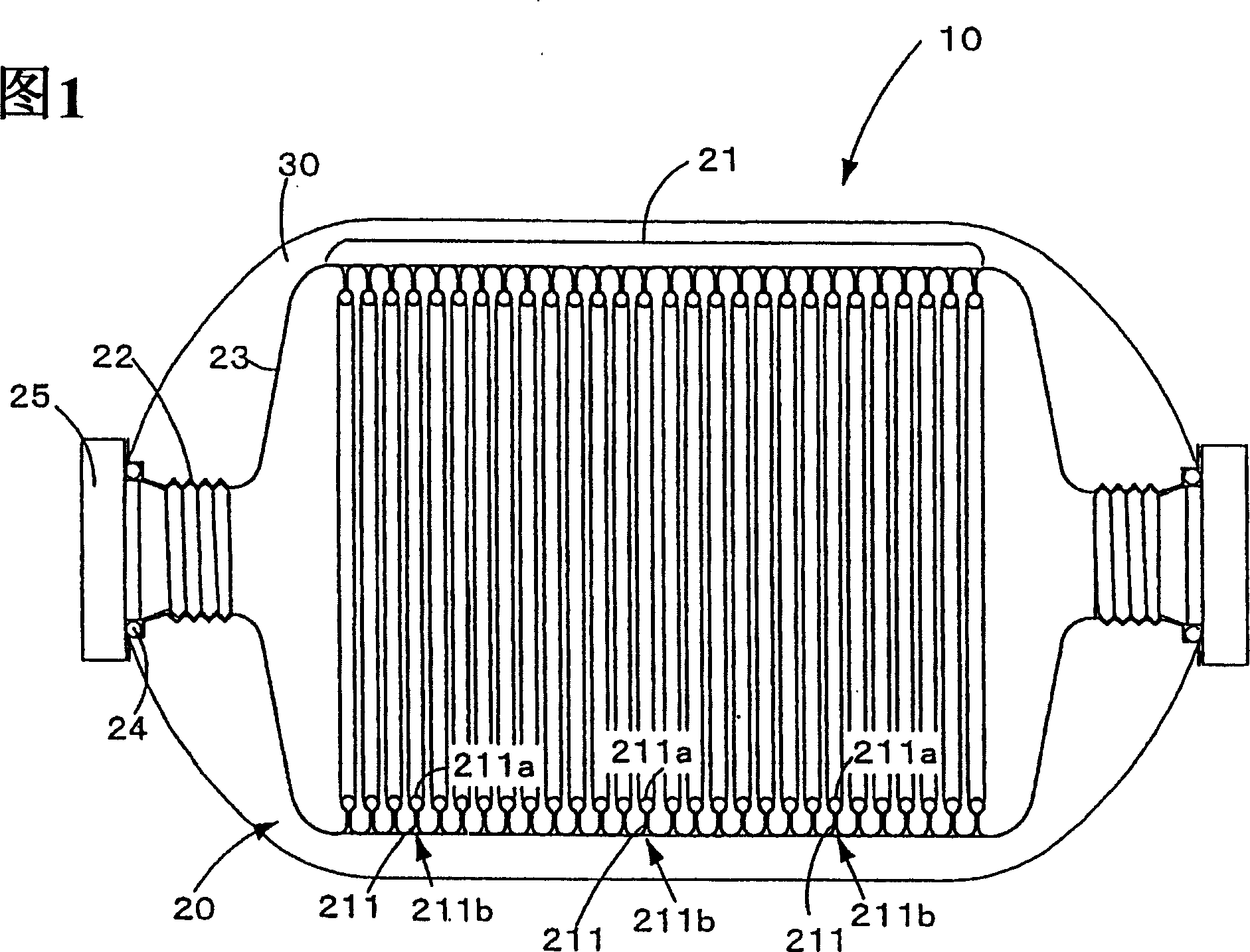

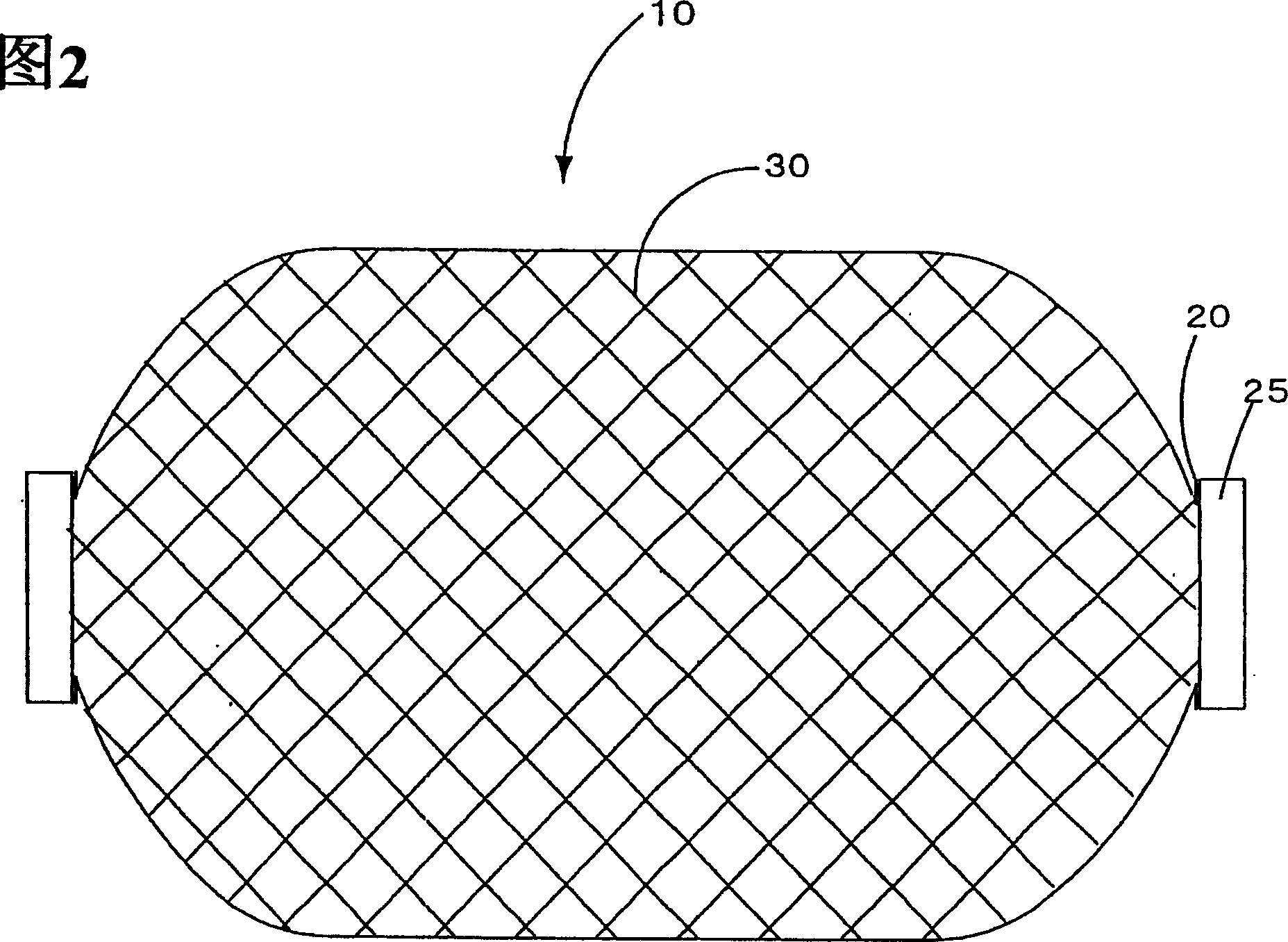

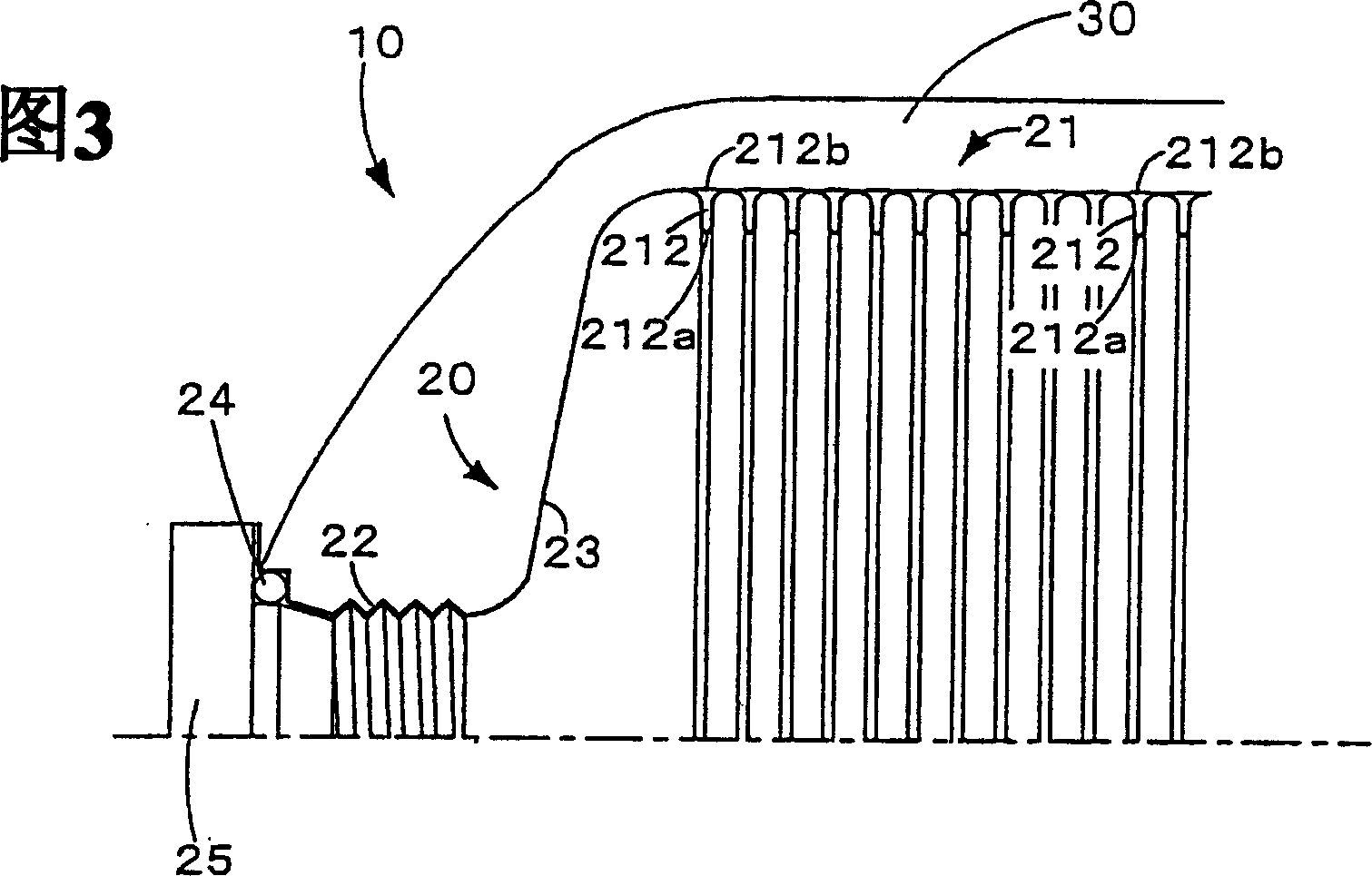

[0060] A high-pressure container according to a first embodiment will be described with reference to FIGS. 1 to 3 . FIG. 1 is an explanatory diagram showing a part in cross-section for explaining the inside of a high-pressure vessel according to the first embodiment. Fig. 2 is an explanatory view showing the appearance of the high-pressure container according to the first embodiment. Fig. 3 is an explanatory view showing a first modified example of the high-pressure container according to the first embodiment.

[0061] The high-pressure container 10 related to the first embodiment has a cylindrical shape as shown in FIG. 2 . In addition, as shown in FIG. Composite shell 30 formed on the outer periphery of the As the metal liner 20, for example, stainless steel, aluminum, or the like can be used.

[0062] The metal liner 20 has a cylindrical body portion 21 , joint portions 22 at both ends, and a cover portion 23 connecting the body portion 21 and the joint portions 22 . Th...

no. 2 Embodiment

[0071] refer to Figure 4 ~ Figure 12 The high-pressure container according to the second embodiment will be described. Figure 4 It is a detailed view showing the inside of the high-pressure vessel according to the second embodiment in detail. Figure 5 It is an explanatory diagram showing a first modified example of the high-pressure container according to the second embodiment. Figure 6 It is an explanatory diagram showing a second modified example of the high-pressure container according to the second embodiment. Figure 7 It is an explanatory diagram showing a third modified example of the high-pressure container according to the second embodiment. Figure 8 It is an explanatory diagram showing a fourth modified example of the high-pressure container according to the second embodiment. Figure 9 It is an explanatory diagram showing a fifth modified example of the high-pressure container according to the second embodiment. Figure 10 It is a flowchart showing the manuf...

no. 3 Embodiment

[0086] A high-pressure container according to a third embodiment will be described with reference to FIG. 14 . Fig. 14 is a detailed view showing the interior of the high-pressure container according to the third embodiment. The metal liner 50 of the high-pressure vessel 12 according to the third embodiment is composed of a main body member 52 integrally formed with a helical groove functioning as an expansion and contraction allowing portion and constituting a main body 51, and an opposed main body member. 52 are screwed together to form an end member 53 . In addition, the other components of the high-pressure vessel 12 according to the third embodiment are the same as those of the high-pressure vessel 10 according to the first embodiment, so the same reference numerals are assigned and descriptions thereof are omitted.

[0087] According to the high-pressure vessel 12 according to the third embodiment, since the metal lining 50 can be formed by screwing the end member 53 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com