Electrode assembly with separated support tapes in secondary battery

A technology of electrode components and support bands, which is applied in battery electrodes, secondary batteries, secondary battery manufacturing, etc., and can solve problems such as increasing battery manufacturing costs, reducing battery performance, and increasing batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

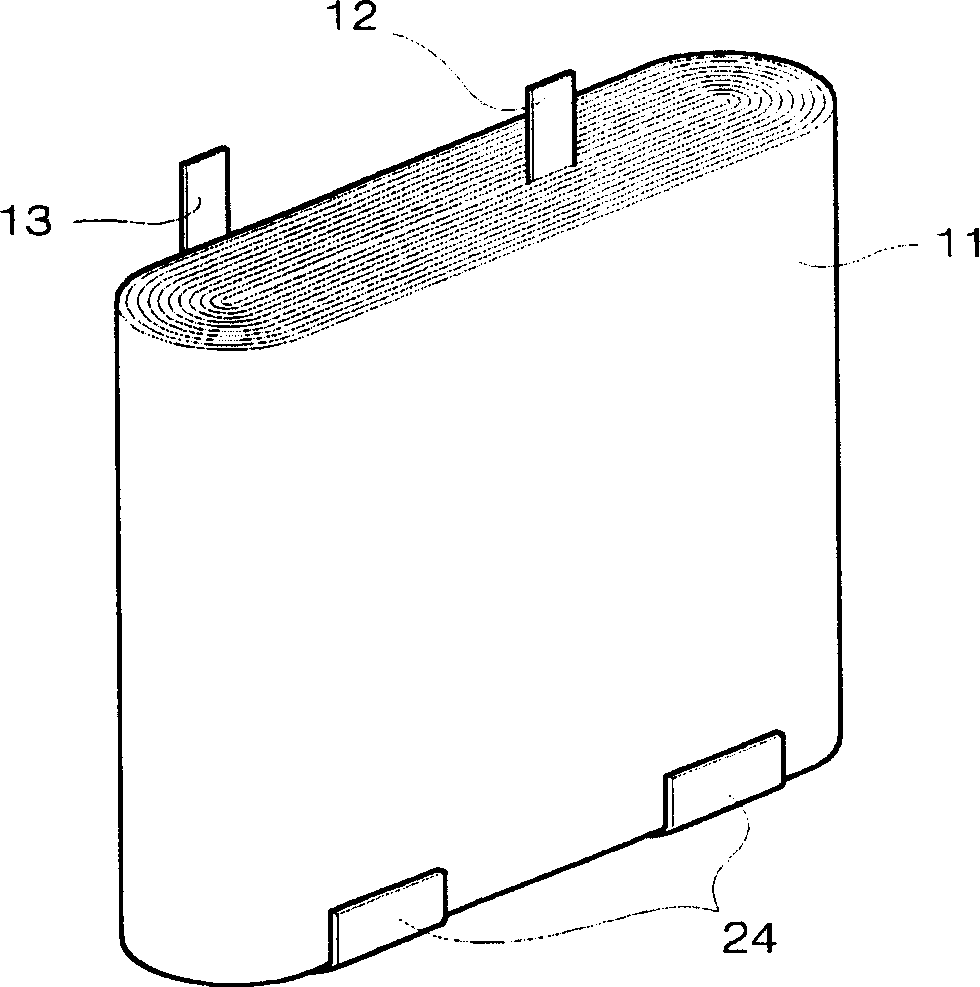

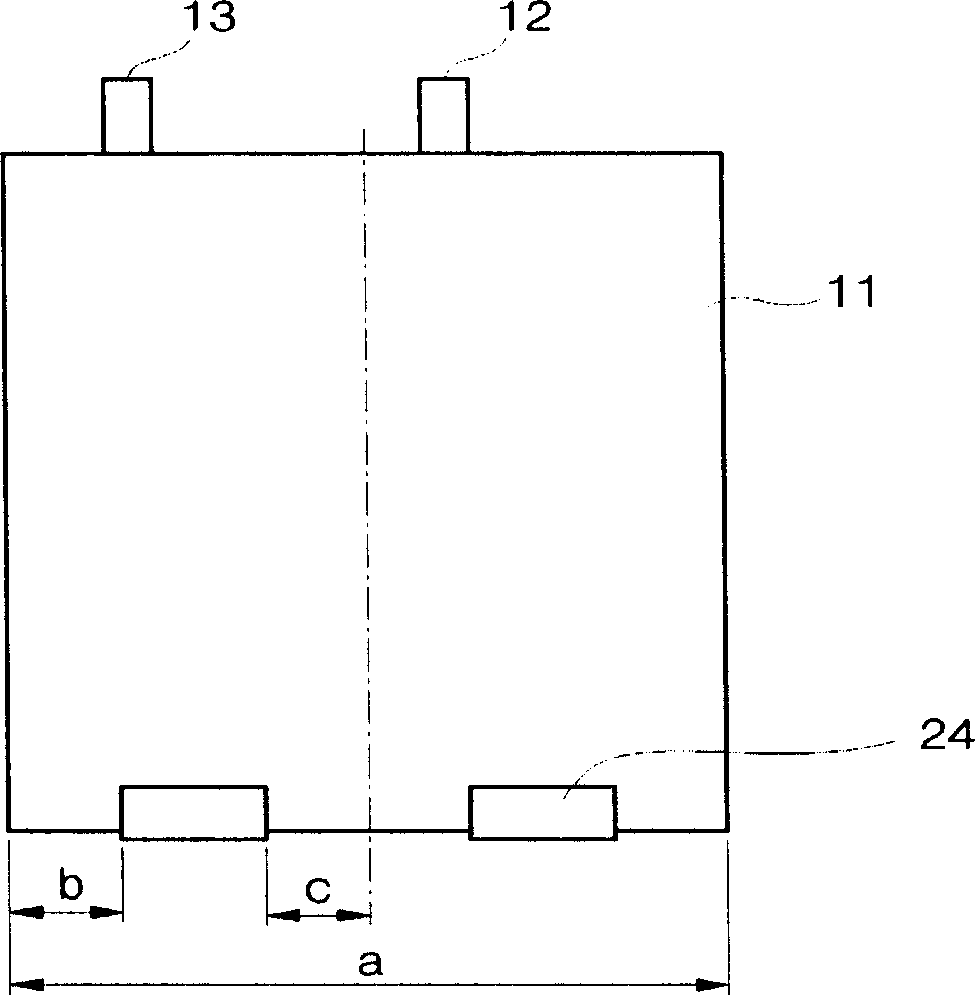

[0028] Figure 2a is a perspective view of an electrode assembly with a divided support band according to an exemplary embodiment of the present invention.

[0029] Such as Figure 2a As shown, the present invention comprises an electrode assembly 11 , a cathode tab 12 , an anode tab 13 and a separate support strip 24 .

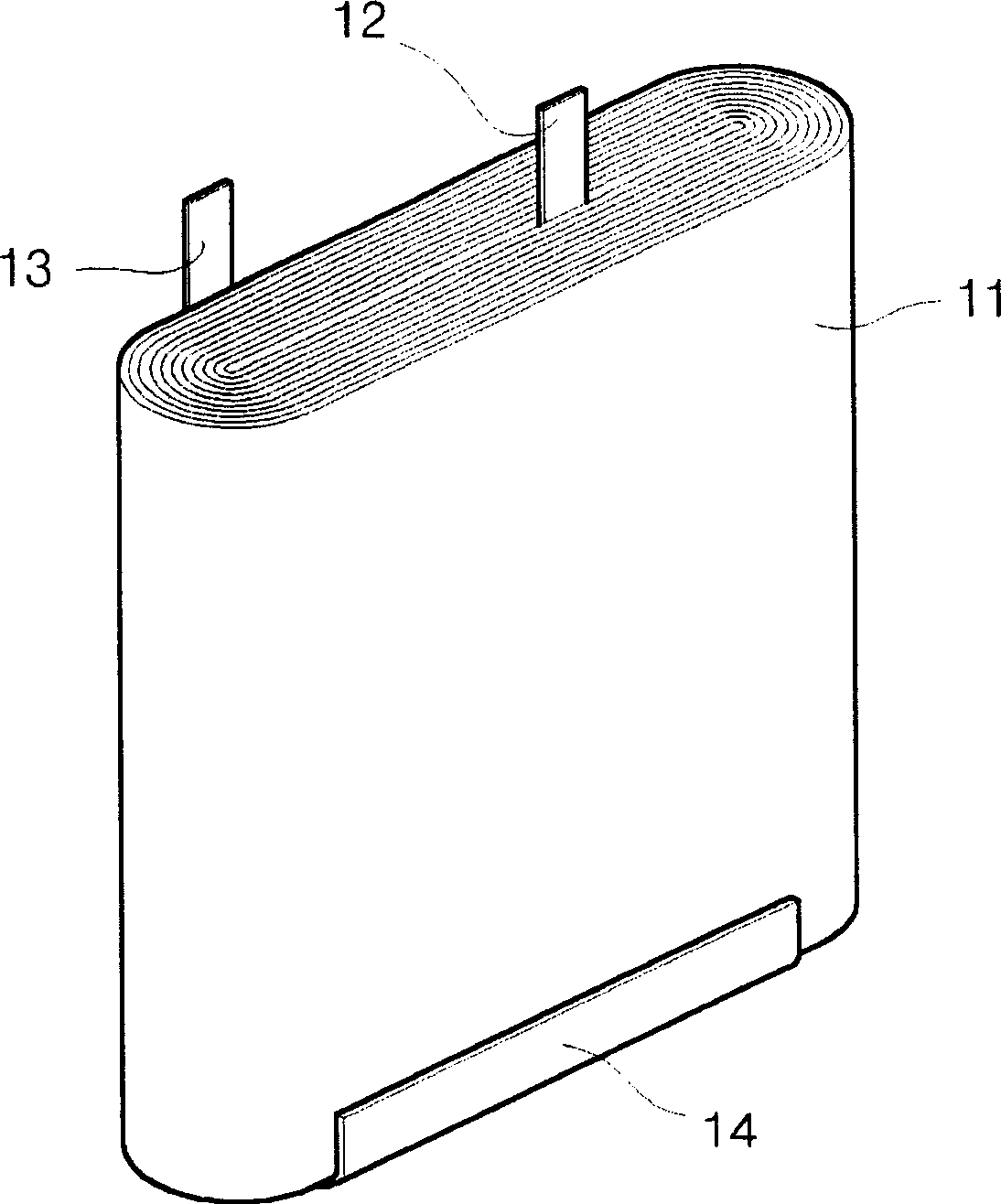

[0030] To manufacture the electrode assembly 11, an active material is applied to both surfaces of the collector. Then, the collector electrode is dried and subjected to roll processing so that the collector electrode is cut into anode plates and cathode plates. In this state, the anode plate and the cathode plate are wound with a separator interposed between the anode plate and the cathode plate to form the electrode assembly 11 . That is, after anode plates and cathode plates are alternately arranged around the separator, an electrode assembly is formed by winding the anode plates and cathode plates in a spiral pattern using an elliptical winding mandrel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com