Air exhausting pipe check valve with natural ventilating and speed variable function

A technology of natural ventilation and exhaust ducts, applied in the direction of functional valves, control valves, valve devices, etc., can solve the problems of no gaps, backflow, and loose closure of valve plates and valve bodies, etc., achieving low cost and convenient use , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

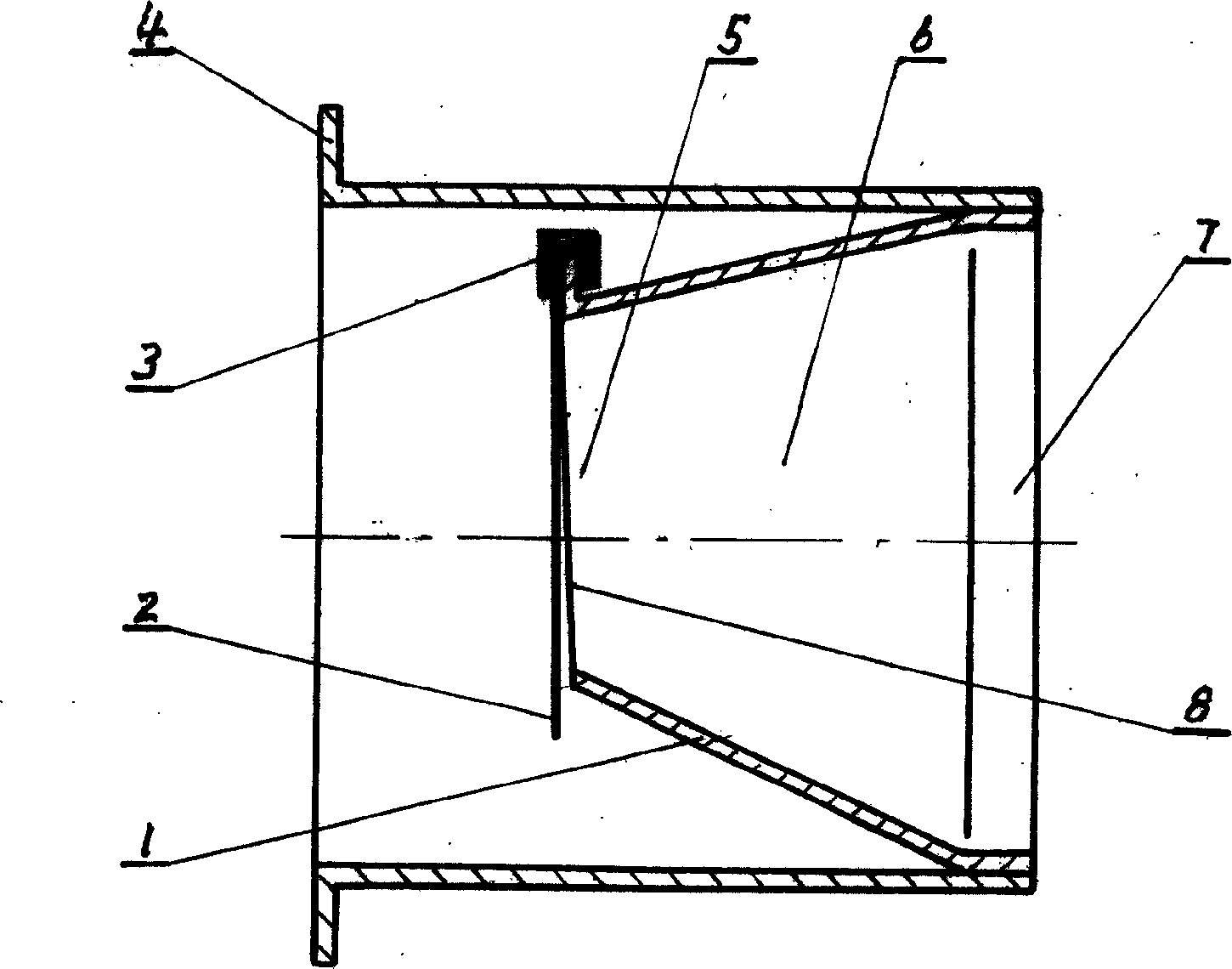

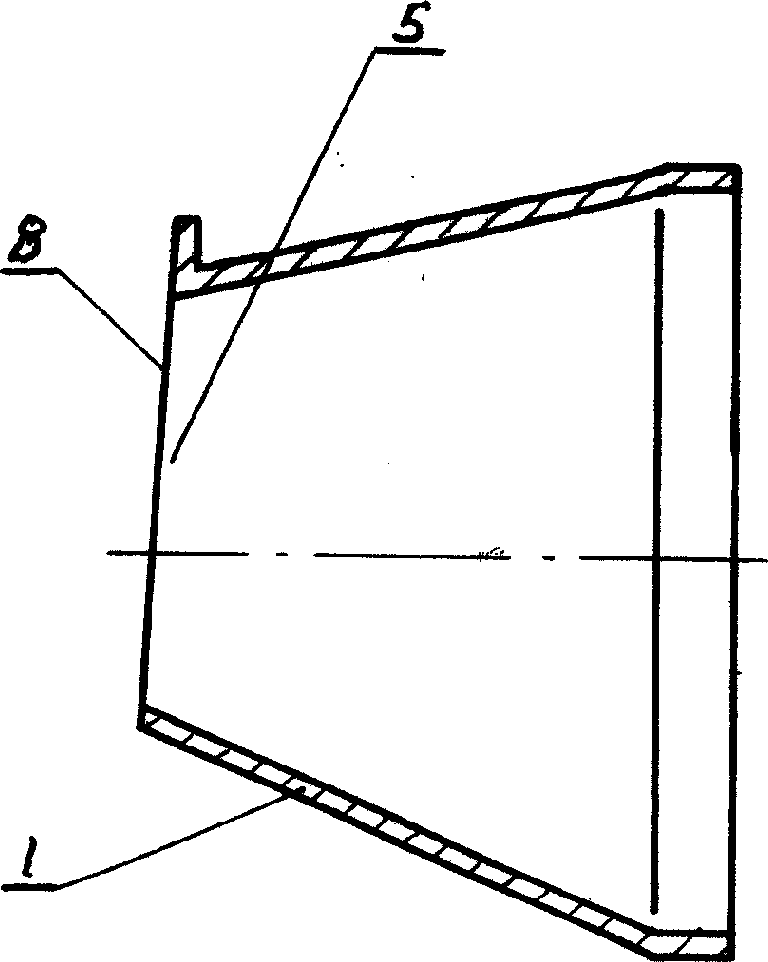

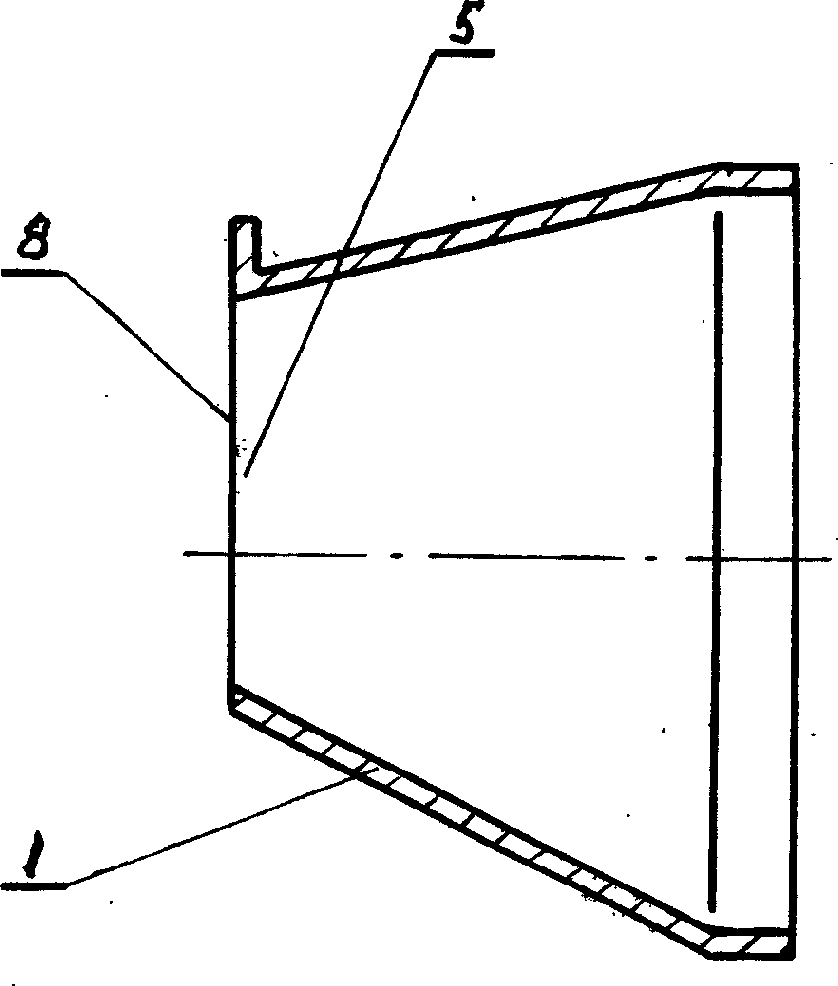

[0013] Such as figure 1 As shown, the present invention includes an interface 4, a valve body 1, and a valve plate 2 that are arranged on the wall of the kitchen exhaust duct and communicate with the exhaust outlet of the exhaust duct and are used to socket the exhaust hose of the range hood. Valve body 1, the airflow passage 6 of valve body 1 is a variable speed hole 6 with 7 large air inlets and 5 small air outlets. The 5 ends of the air outlet of valve body 1 are provided with valve plate 2, and valve plate 2 covers the outlet of valve body 1. There are 8 places on the end face of the tuyere 5.

[0014] The valve sheet 2 is made of flexible material, and the external dimensions of the valve sheet 2 are larger than the external dimensions of the end surface 8 of the air outlet 5 of the valve body 1 .

[0015] The arrangement of the valve plate 2 at the air outlet 5 of the valve body 1 is that the valve plate 2 is fastened to the upper end of the air outlet 5 of the valve bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com