Optical device and movable reflector

A technology of optical parts and light reflection, applied in optical components, optics, light guides, etc., can solve problems such as signal light waveform distortion, communication errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

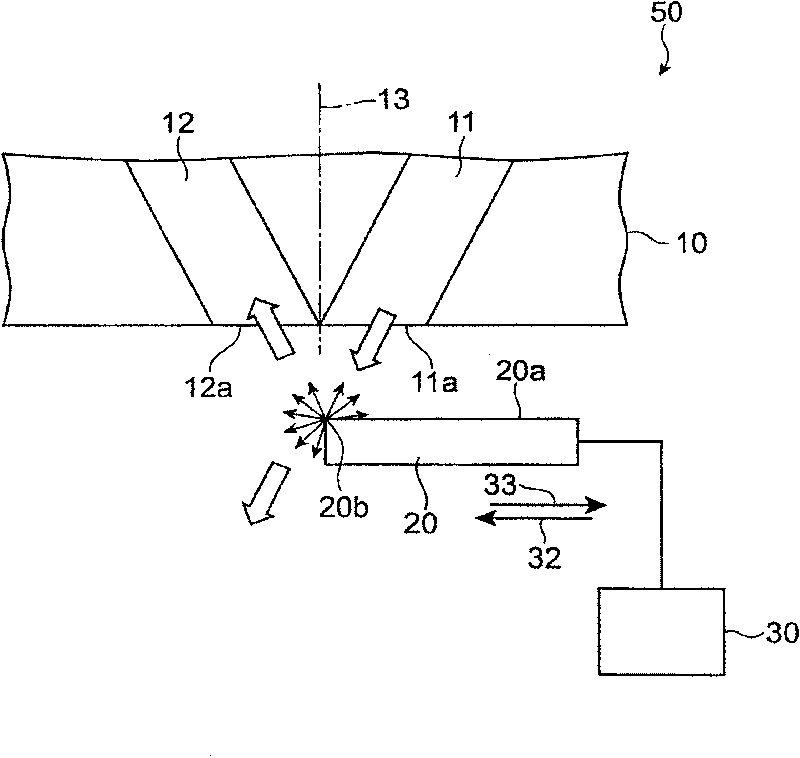

[0054] Figure 4 It is a schematic plan view showing the optical component of Embodiment 1. The optical component is a variable optical attenuator 100 . The variable optical attenuator 100 has a planer lightwave circuit (Planer Lightwave Circuit: PLC) 10 , a movable mirror 21 , and a mirror driving device 30 . The mirror 21 and the mirror driving device 30 constitute a movable reflecting device 91 . These components are housed in a housing (not shown).

[0055] PLC10 has two optical waveguides 11 and 12. The optical waveguides 11 and 12 are along Figure 4 A planar waveguide that extends parallel to the paper surface. The optical waveguides 11 and 12 are made of quartz glass, for example. The optical waveguides 11 and 12 are such as Figure 4 As shown, the reference plane 13 perpendicular to the paper surface has symmetrical (in this embodiment, mirror symmetrical) end portions. These end portions extend linearly with an inclination of an angle α with respect to the refere...

Embodiment approach 2

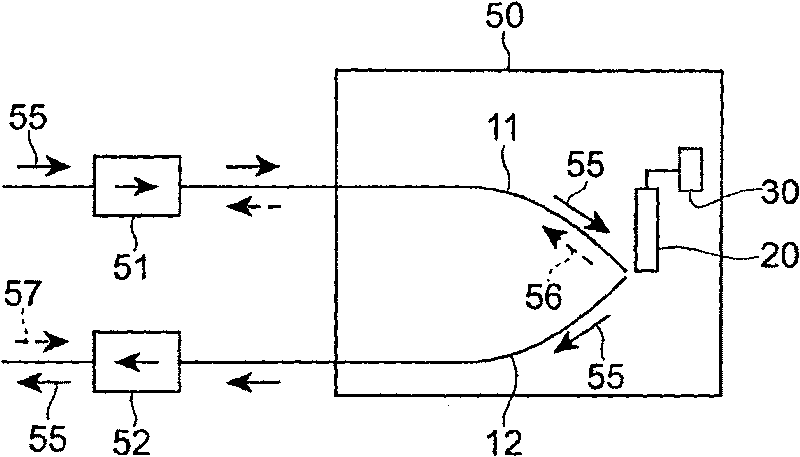

[0068] Figure 8 It is a schematic plan view showing the variable optical attenuator 200 of the second embodiment. The variable optical attenuator 200 includes a PLC 60 instead of the PLC 10 in the variable optical attenuator 100 of the first embodiment. Another configuration of the variable optical attenuator 100 is the same as that of the first embodiment.

[0069] The PLC 60 has three optical waveguides 61 , 62 and 63 . These optical waveguides are compatible with Figure 8 A planar waveguide that extends parallel to the surface of the paper is made of, for example, quartz glass. The optical waveguides 61 and 62 have an optical axis 68 including the optical waveguide 63, and are relatively Figure 8 The reference plane perpendicular to the plane of the paper is arranged as symmetrical (mirror symmetrical in this embodiment) ends. These end portions each extend in a straight line with an inclination of an angle α with respect to the optical axis 68 . These ends therefo...

Embodiment approach 3

[0074] Figure 9 It is a schematic plan view showing the variable optical attenuator 300 of the third embodiment. The variable optical attenuator 300 has a movable mirror 22 instead of the movable mirror 21 in the variable optical attenuator 100 of the first embodiment. The mirror 22 and the mirror driving device 30 constitute a movable reflecting device 92 . Other configurations of the variable optical attenuator 300 are the same as those of the first embodiment.

[0075] The movable mirror 22 is a light reflector having a light reflection surface 22a. Movable mirror 22 is with Figure 9 A columnar body that extends vertically to the plane of the paper and has a section along the same vertical direction as the plane of the paper. The light reflection surface 22a has an extremely high reflectance (for example, 90% or more) with respect to light of a predetermined wavelength propagating through the optical waveguides 11 and 12 . The light reflection surface 22 a faces the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com