Preparation method of high stability adhesive

A high-stability, adhesive technology, applied in the direction of protein waste adhesives, etc., can solve the problems of bone glue easy to mildew, viscosity drop, loss of bonding performance, etc., to achieve neutrality, enhanced adhesion, and enhanced The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

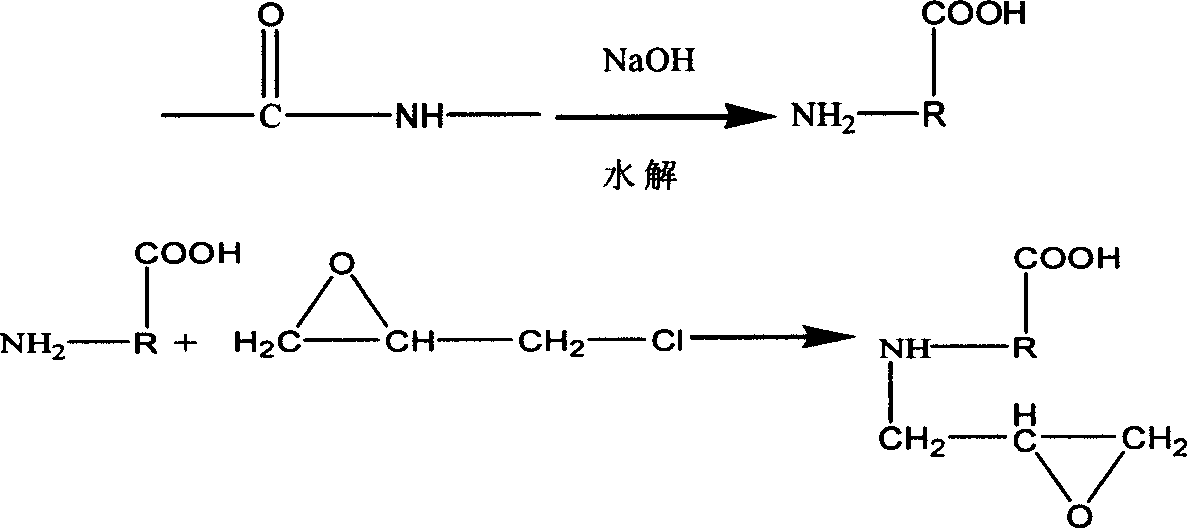

Method used

Image

Examples

Embodiment 1

[0006] Example 1: first mix the bone glue and water in a mass ratio of 1:1, so that the bone glue is fully swollen to form a glue solution; when the water bath is at a constant temperature of 65°C, add 0.5 parts of 20% by mass concentration to every 100 parts of the glue solution NaOH, stir for 40 minutes; cool down to 50°C, slowly add 1.2 parts of epichlorohydrin dropwise to every 100 parts of the glue with NaOH added, and stir until the viscosity increases significantly; add 0.2 parts to every 100 parts of the glue Preservative sodium benzoate was added, and the pH value was adjusted to pH=8 with glacial acetic acid, and the reaction was continued for 25 minutes to obtain a yellow-brown viscous liquid.

Embodiment 2

[0007] Example 2: first mix the bone glue and water at a mass ratio of 1:1.3, so that the bone glue is fully swollen to form a glue; when the water bath is kept at a constant temperature of 58°C, add 1.5 parts of 20% of the mass percentage concentration to every 100 parts of the glue NaOH, stir for 36 minutes; cool down to 46°C, slowly add 1.1 parts of epichlorohydrin dropwise to every 100 parts of the above glue with NaOH added, stir until the viscosity increases significantly; add 0.1 parts to every 100 parts of the glue Preservative sodium benzoate was added, and the pH value was adjusted to pH=8 with glacial acetic acid, and the reaction was continued for 35 minutes to obtain a yellow-brown viscous liquid.

Embodiment 3

[0008] Example 3: first mix the bone glue with water at a mass ratio of 1:1.1, so that the bone glue is fully swollen to form a glue solution; when the temperature of the water bath is constant at 55°C, add 1.2 parts of 20% glucosinolate to every 100 parts of the glue solution NaOH, stir for 30 minutes; cool down to 40°C, slowly add 1.0 parts of epichlorohydrin dropwise to every 100 parts of the glue with NaOH added, stir until the viscosity increases significantly; add 0.1 parts to every 100 parts of the glue Preservative sodium benzoate was added, and the pH value was adjusted to pH=8 with glacial acetic acid, and the reaction was continued for 32 minutes to obtain a yellow-brown viscous liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com