System for influencing the rheological properties of a transportable material

A rheological property, transmission direction technology, applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problem of reducing the quality of processed/handled materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

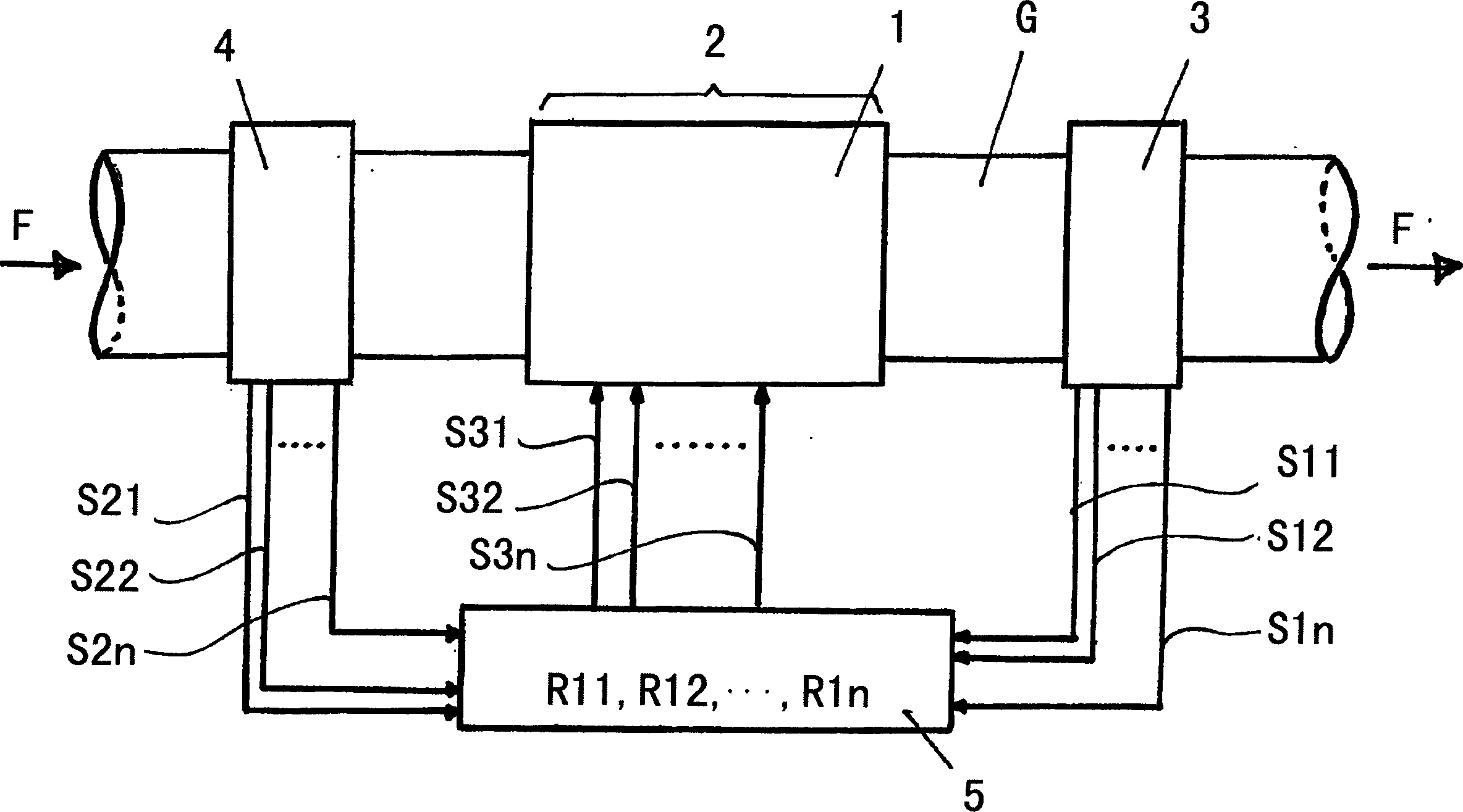

[0045] figure 1 is the system of the present invention as a schematic block diagram. The conveyed material whose rheological properties are influenced by the system according to the invention flows along the conveying direction F through the plant part with the housing part G. At one end thereof, the controllable crash system 1 is arranged on the housing part G of the processing part located in the region of the processing part 2 of the plant. The first detection system 3 and the second detection system 4 are arranged upstream and downstream of the housing part G, respectively, with respect to the processing part 2 of the plant. The first and second detection systems 3 , 4 are used to acquire the rheological properties of the conveyed material upstream and downstream of the processing section 2 . The first detection system 3 is used to generate first signals S11 , S12 , . The second detection system 4 is used to generate second signals S21 , S22 , .

[0046] The first sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com