Cross-section fiber containing metal-modified cross-shaped ester compound and preparation method thereof

A metal modification, cross-shaped technology, applied in the chemical characteristics of fibers, rayon manufacturing, fire-retardant and flame-retardant filament manufacturing, etc., can solve problems such as poor moisture absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A method for preparing a cross-section fiber containing a metal-modified cross-shaped ester compound, the steps are as follows:

[0065] (1) prepare metal-modified cruciform ester compound;

[0066] (a1) preparing a cruciform ester compound;

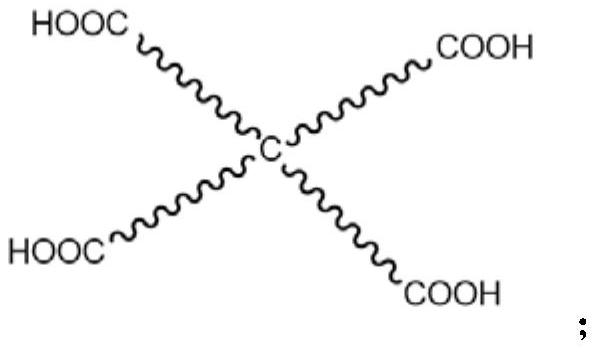

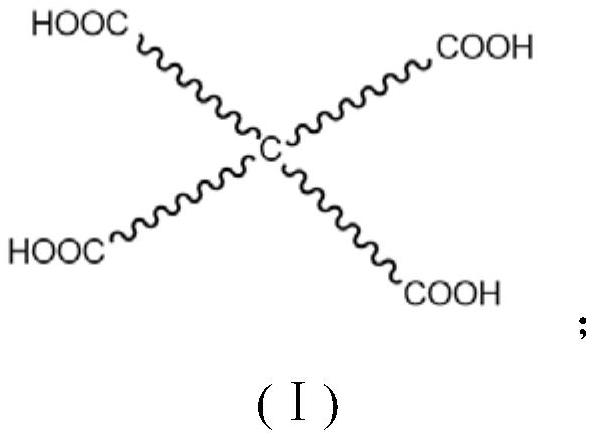

[0067] (a11) Dibasic acid A 2 Mix with pentaerythritol at a molar ratio of 4:1, carry out melt esterification reaction under nitrogen protection and mechanical stirring at a stirring speed of 300rpm, collect the product, obtain DAPER through dissolution, filtration and drying, wherein the temperature of the melt esterification reaction is 200°C, the reaction time is 3h, A 2 The structural formula is:

[0068]

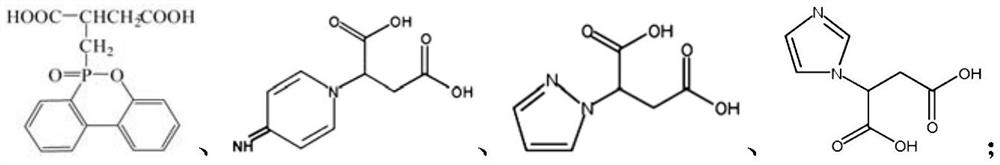

[0069] (a12) Dibasic carboxylic acid B 2 Mix with ethylene glycol at a molar ratio of 1:1, add 4-methylbenzenesulfonic acid, and carry out melt condensation reaction under nitrogen protection and mechanical stirring at a stirring speed of 500rpm to obtain DADA, wherein B 2 The molar ratio with 4-methylbenzenesulfoni...

Embodiment 2

[0088] A method for preparing a cross-section fiber containing a metal-modified cross-shaped ester compound, the steps are as follows:

[0089] (1) prepare metal-modified cruciform ester compound;

[0090] (a1) preparing a cruciform ester compound;

[0091] (a11) Dibasic acid A 2 Mix with pentaerythritol at a molar ratio of 4:1, carry out melt esterification under argon protection and mechanical stirring at a stirring speed of 350rpm, collect the product, dissolve, filter and dry to obtain DAPER, wherein the melt esterification The temperature is 185°C, the reaction time is 1h, A 2 The structural formula is:

[0092]

[0093] (a12) Dibasic carboxylic acid B 2 Mix with propylene glycol at a molar ratio of 1:1, add 4-methylbenzenesulfonic acid, and carry out melt condensation reaction under nitrogen protection and mechanical stirring at a stirring speed of 300rpm to obtain DADA, wherein B 2 The molar ratio with 4-methylbenzenesulfonic acid is 1:0.01, the temperature of t...

Embodiment 3

[0112] A method for preparing a cross-section fiber containing a metal-modified cross-shaped ester compound, the steps are as follows:

[0113](1) prepare metal-modified cruciform ester compound;

[0114] (a1) preparing a cruciform ester compound;

[0115] (a11) Dibasic acid A 2 Mix with pentaerythritol at a molar ratio of 4:1, carry out melt esterification under the condition of helium protection and mechanical stirring at a stirring speed of 400rpm, collect the product, obtain DAPER through dissolution, filtration and drying, wherein the melt esterification The temperature is 180°C, the reaction time is 2h, A 2 The structural formula is:

[0116]

[0117] (a12) Dibasic carboxylic acid B 2 Mix with 1,4-butanediol at a molar ratio of 1:1, add 4-methylbenzenesulfonic acid, and carry out melt condensation reaction under argon protection and mechanical stirring at a stirring speed of 500rpm to obtain DADA, wherein B 2 The molar ratio with 4-methylbenzenesulfonic acid is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com