Friction-reducing agent for oil-based drilling fluid

An oil-based drilling fluid, a technology for reducing friction and drag, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of stuck drilling tools, large friction resistance, dragging pressure, etc. Simple method and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

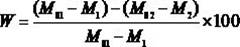

Method used

Image

Examples

Embodiment 1

[0014] Add 40g of Group II base oil, 50g of sulfonated castor oil, and 5g of tricresyl phosphate into the reaction kettle in turn, raise the temperature to 35°C, add 5g of monosuccinimide, and stir evenly to obtain a friction reducing agent for oil-based drilling fluid .

Embodiment 2

[0016] Add 50g of Group II base oil, 40g of sulfonated tall oil, and 5g of di-n-butyl phosphite to the reaction kettle in sequence, raise the temperature to 40°C, add 5g of bis-succinimide, and stir evenly to obtain a friction-reducing oil-based drilling fluid. Drag reducer.

Embodiment 3

[0018] Add 60g of Group II base oil, 30g of sulfurized triglycerides, and 5g of tricresyl phosphate into the reaction kettle in sequence, raise the temperature to 45°C, add 5g of polysuccinimide, and stir evenly to obtain friction and drag reduction for oil-based drilling fluids agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com