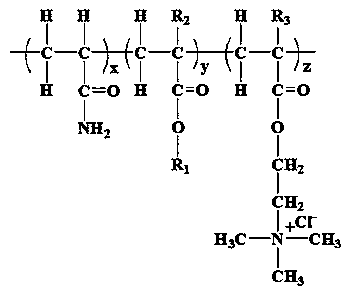

A kind of high temperature resistant cationic polyacrylamide inhibitor and its preparation method and application

A technology of polyacrylamide and acrylamide, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of high temperature resistance and low resistance, and achieve good inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

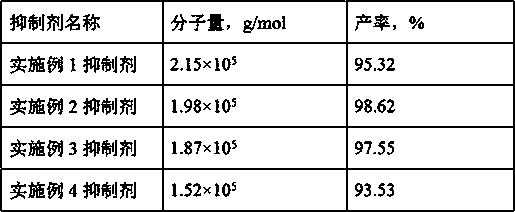

Examples

Embodiment 1

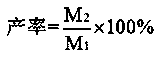

[0027] Method for preparing high temperature resistant cationic polyacrylamide inhibitor

[0028] At 25°C, according to the mass percentage of monomers, 60% of acrylamide, 38% of methacryloyloxyethyltrimethylammonium chloride, and 2% of lauryl methacrylate were dissolved in 70% free In the solvent formed by water ethanol and 30% butyl acetate by volume percentage, a reaction liquid with a concentration of 5% of the total mass percentage of monomers was prepared; after the reaction liquid was passed through nitrogen to remove oxygen for 10-30 minutes, azobisisobutyronitrile was added The mass concentration of the ethanol solution is 5%, and the addition amount of azobisisobutyronitrile is 0.2% of the total mass of the monomer; then the temperature is raised to 70°C, and the reaction is carried out for 7 hours; after the reaction is completed, the reaction solution is filtered or centrifuged to obtain Powdered solid, namely high temperature resistant cationic polyacrylamide inhi...

Embodiment 2

[0030] Method for preparing high temperature resistant cationic polyacrylamide inhibitor

[0031] At 25°C, according to the mass percentage of monomers, 60% of acrylamide, 38% of methacryloyloxyethyltrimethylammonium chloride, and 2% of lauryl methacrylate were dissolved in 80% free In the solvent formed by water ethanol and 20% butyl acetate by volume percentage, a reaction liquid with a total mass percentage concentration of monomers of 5% was prepared; after the reaction liquid was purged with nitrogen for 10-30 minutes, azobisisobutyronitrile was added The mass concentration of the ethanol solution is 5%, and the addition amount of azobisisobutyronitrile is 0.2% of the total mass of the monomer; then the temperature is raised to 70°C, and the reaction is carried out for 7 hours; after the reaction is completed, the reaction solution is filtered or centrifuged to obtain Powdered solid, namely high temperature resistant cationic polyacrylamide inhibitor.

Embodiment 3

[0033] Method for preparing high temperature resistant cationic polyacrylamide inhibitor

[0034] At 25°C, according to the mass percentage of monomers, 60% of acrylamide, 39% of acryloyloxyethyltrimethylammonium chloride, and 2% of hexadecyl methacrylate were dissolved in 80% free In the solvent formed by water ethanol and 20% butyl acetate by volume percentage, the reaction liquid with the total mass percentage concentration of the monomers being 4% is prepared; Ethanol solution with a mass concentration of 5%, the amount of benzoyl peroxide added is 0.2% of the total mass of the monomer; then the temperature is raised to 80°C, and the reaction is carried out for 4 hours; after the reaction, the reaction solution is filtered or centrifuged to obtain a powder Solid, that is, high temperature resistant cationic polyacrylamide inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com